Dec . 04, 2024 10:26 Back to list

Understanding the Composition of HPMC and Its Uses in Various Applications

What is HPMC Made From?

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether widely used in various industries, including pharmaceuticals, food, cosmetics, and construction. Understanding what HPMC is made from is crucial for its application and its properties. This article aims to delve into the composition, production process, and applications of HPMC.

Composition of HPMC

HPMC is derived from cellulose, which is a naturally occurring polymer found in the cell walls of plants. Cellulose itself is made up of long chains of glucose molecules linked together by β-1,4-glycosidic bonds, forming a structure that is non-soluble in water due to its strong hydrogen bonding. To create HPMC, cellulose undergoes several chemical modifications.

The production process begins with the extraction of cellulose from natural sources, such as wood pulp or cotton. This cellulose is then subjected to a process known as etherification, which involves reacting the cellulose with propylene oxide and methyl chlorine in the presence of an alkaline catalyst. This reaction introduces hydroxypropyl and methyl groups onto the cellulose chain, which changes the solubility and viscosity of the product.

The extent of hydroxypropyl and methyl substitution can be varied, which allows manufacturers to produce HPMC with different physical properties and solubility characteristics. For instance, the degree of substitution affects the viscosity, transparency, and thickness of the resulting product, making HPMC suitable for a wide range of applications.

Production Process

The production of HPMC is a multi-step chemical process that can be broken down into several key phases

1. Cellulose Extraction The first step involves extracting cellulose from natural sources. This is usually done through the pulping and bleaching of wood or cotton fibers to ensure high purity.

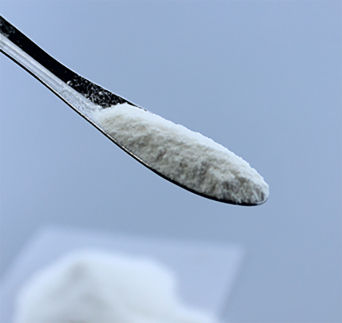

what is hpmc made from

2. Pre-treatment The purified cellulose fibers are treated with a series of chemicals to prepare them for etherification. This usually includes drying and milling the cellulose to obtain a fine powder that increases the surface area for the subsequent reactions.

3. Etherification The critical step in HPMC production, where the dry cellulose is reacted with propylene oxide and methyl chloride. This reaction can take place in an organic solvent or in an aqueous environment, depending on the desired characteristics of the final product.

4. Neutralization and Drying After the etherification reaction, the products are neutralized to remove any unreacted chemicals, and the resulting HPMC is filtered and dried. The final product is a white, odorless powder that is soluble in cold water.

Applications of HPMC

HPMC has a broad range of applications due to its unique properties. In the pharmaceutical industry, it is commonly utilized as a binder, thickener, and film-forming agent in drug formulations. Its ability to control the release of active ingredients makes it a crucial component in controlled-release medications.

In the food industry, HPMC is used as a food additive, emulsifier, and stabilizer. It helps improve the texture and shelf-life of various food products. Additionally, in the cosmetics industry, HPMC acts as a thickening and gelling agent, enhancing the consistency and feel of creams and lotions.

In construction, HPMC is valued for its water-retaining properties and is widely used in cement-based products to improve workability and adhesion.

Conclusion

In summary, HPMC is made from cellulose through a specialized process of etherification. Its unique chemical structure allows it to serve various functions across many industries, contributing to advancements in pharmaceuticals, food technology, cosmetic formulations, and construction materials. The versatility and effectiveness of HPMC make it an indispensable material in modern applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025