- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

About Jing Zuan

Jingzuan chemical technology is specialized in the production of HPMC, HEC, HEMC and RDP for more than 15 years. We are located in Shijiazhuang city, north China, about 300 km to Beijing, also about 300 km to Tianjin sea port.

We were established by 2008, with annual capacity of 30,000 tons. Through development of a decade, supported and welcomed by our customers all over the world. We then invested 23 million dollars on the new production line with Germany technology in 2021. With production annual capacity of 60,000 tons for HPMC, 15,000 tons for HEC, 15,000 tons for HEMC and 20,000 tons for RDP.

We have strict quality control system, and acquired the ISO 9001 certificate, CE certificate and accept all types of test by third party. We have a professional team, composed of production and application engineers. And equipped by whole set of advanced laboratory equipment and devices. Which ensures stable and best quality products to be supplied.

Our goal is sparing no efforts to make all our users and customers competitive in the market, and together with all our friends, make our the best contribution to the construction field.

Jingzuan will always keep the quality and the concerns of our buyers in mind, will only and always make the best quality product that is suitable to certain applications for the buyers. We are not only supplying the products, but also supplying our services, and experienced chemical solutions to each of our buyers.

Jingzuang Chemical was established since 2006. With the rapid developing these years, we newly invested a brand new production line with the production capacity of 60,000 tons per year. With German equipment and technology,we can provide very stable and high quality products with very short lead time. Here please let me take you for a tour around our factory.

-

This is our refined cotton storage warehouse. We consume about 40,000 tons of refined cotton each year. To ensure our quality stability, we have strict raw material check and quality control. From the livestreams you may witness the change and consumption of the cottons clearly.

-

These tanks are the chemical gas tanks. Mainly storaging liquid alkali, methane and propylene oxide.

-

Refined cotton feeding and crushing progress.

-

Temporary storage silos for ready crushed cotton.

-

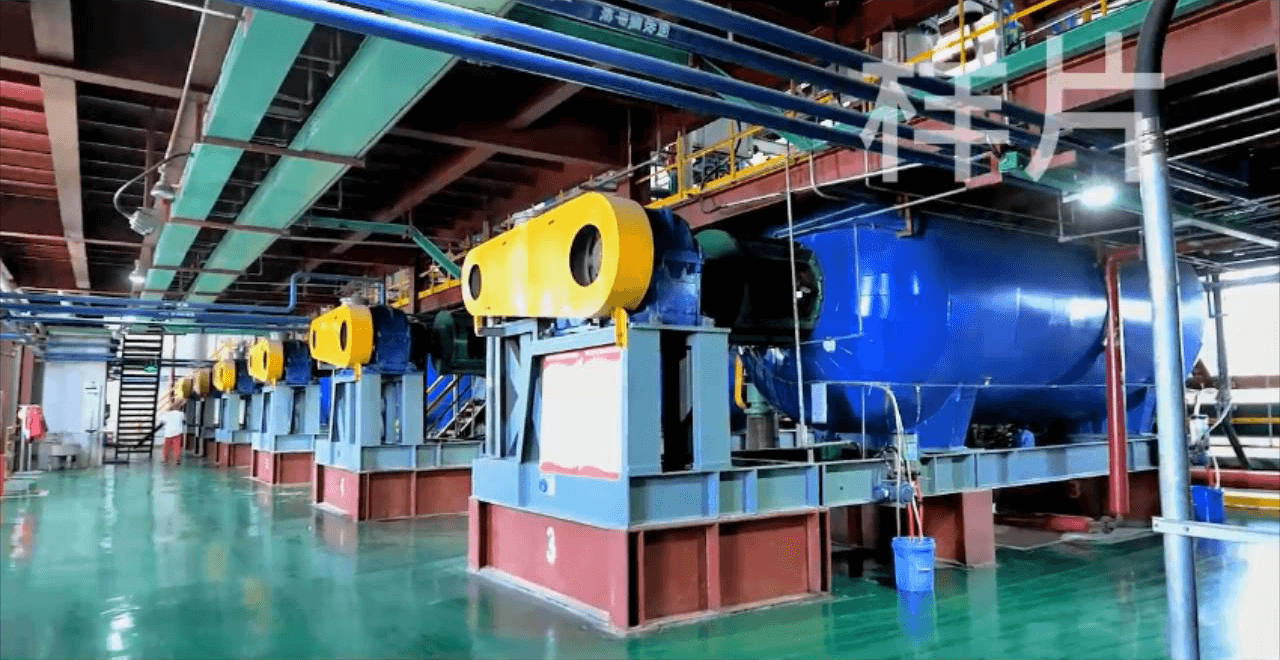

Reaction kettles. We've got 10 sets of reaction kettles, which ensures the annual capacity of 60,000 tons.

-

Gas recycling tanks.

-

Dust collectors.

-

Viberators.

-

Bagging-off.

-

Pallet wrapping.

-

Central control room.

-

Water treatment. With full set of water treatment, we can ensure the lead time and won't be delaied by the environmental inspection issues.

-

Our lab. We can test the purity, viscosity, liquid transmittance rate and water retention etc. We will keep samples for each batch before delivery after test and check.