Dec . 07, 2024 16:40 Back to list

Applications and Benefits of Redispersible Polymer Powders in Various Industries

The Versatile Uses of Redispersible Polymer Powder

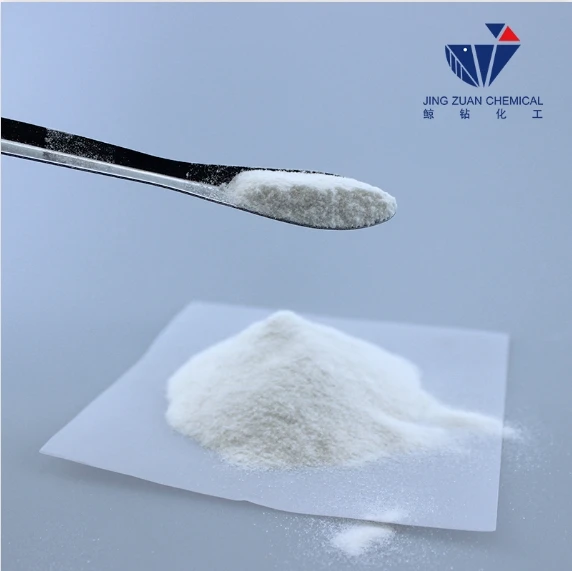

Redispersible polymer powder (RDP) is an innovative material widely used in construction and building applications, offering excellent performance characteristics that enhance the properties of various formulations. Ideally, RDP is produced by spray-drying a polymer emulsion, leading to a fine powder. When mixed with water, it redisperses back into its original emulsion form, enabling the polymers to form a continuous film. This unique property makes RDP a favored additive across multiple industries, primarily in construction, adhesive manufacturing, and specialty coatings.

One of the primary applications of redispersible polymer powder is in cement-based formulations such as tile adhesives and grouts. In these applications, RDP enhances workability, flexibility, and adhesion strength. The addition of RDP improves the open time, enabling easier application, ensuring that the tile adhesive maintains its tackiness for extended periods. Furthermore, it enhances the water resistance and reduces the likelihood of cracking or delamination, which is crucial for maintaining longevity in high-stress environments such as floors and walls.

The Versatile Uses of Redispersible Polymer Powder

RDP is also a critical component in the production of self-leveling underlayments. In these applications, it helps to ensure better flow properties while also contributing to the setting time and final hardness of the mixture. The result is a smoother, more uniform surface that sets quickly but retains adequate strength. Its inclusion boosts the resilience of the underlayment, making it less prone to early-age cracking.

redispersible polymer powder uses

Besides its applications in flooring and wall systems, redispersible polymer powder is a popular additive in the manufacture of paints and coatings. RDP imparts superior adhesion and flexibility to paint products, making them suitable for a wide range of substrates, including metal, wood, and plastic. The incorporation of RDP can enhance the durability and weather resistance of paints, making them ideal for exterior applications subjected to harsh conditions.

Another noteworthy application is in the production of dry-mix mortars. These pre-blended powder products benefit immensely from the addition of RDP, which improves the mortar's performance characteristics. Enhanced adhesion, workability, and reduced water absorption are some of the advantages that RDP brings to dry-mix systems. As such, it is a common ingredient in façade systems, repair mortars, and other specialized formulations.

The construction industry is not the only sphere benefiting from redispersible polymer powder. It is increasingly finding its way into the highway and infrastructure sectors. In applications such as asphalt pavements and concrete repair, RDP enhances adhesion and flexibility, ensuring long-lasting durability in demanding environments such as roads and bridges.

In conclusion, the versatility of redispersible polymer powder makes it an invaluable material across various industries, particularly in construction. Its ability to improve adhesion, flexibility, water resistance, and overall durability makes it an essential additive in a multitude of products ranging from adhesives to coatings. As innovation continues in the polymer chemistry field, the use of RDP is expected to expand further, offering new solutions to meet the growing demands of modern construction and manufacturing challenges.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025