Sep . 28, 2024 18:08 Back to list

redispersible polymer powder manufacturers

Understanding Redispersible Polymer Powder Manufacturers

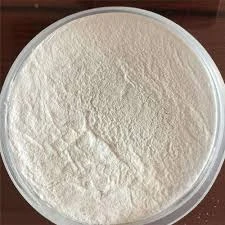

Redispersible polymer powders (RPP) have revolutionized the construction industry, providing significant benefits in terms of performance, workability, and sustainability. These versatile materials are essentially dry powders that can be easily redispersed in water to create a stable, polymer-modified solution. This article explores the role of manufacturers in producing high-quality redispersible polymer powders and their impact on various applications, particularly in construction materials.

RPP is primarily used in cement and gypsum-based formulations, improving adhesion, flexibility, and water resistance of mortars and plasters. This is especially crucial in construction, where the durability and longevity of materials are paramount. Manufacturers have developed various formulations of polymer powders, tailored to meet specific requirements of application, climate, and substrate types.

One of the main considerations for manufacturers is the raw materials used in the production of redispersible polymer powders. Typically, these powders are made from polyvinyl acetate (PVAc), styrene-butadiene (SB), and acrylic polymers. The choice of polymer influences the end product's properties, such as adhesion strength, elasticity, and thermal stability. Therefore, manufacturers often invest in extensive research and development (R&D) to create formulations that meet the demanding standards of the construction industry.

redispersible polymer powder manufacturers

Quality control is another critical aspect of production for redispersible polymer powder manufacturers. The powders must undergo rigorous testing to ensure consistency, performance, and compliance with international standards. This includes tests for particle size distribution, dispersion properties, and compatibility with various binders and additives. Reliable manufacturers implement stringent quality assurance measures to guarantee that their products perform as advertised, providing peace of mind for contractors and builders.

Sustainability is becoming increasingly vital for consumers and manufacturers alike. Many redispersible polymer powder manufacturers are now focusing on eco-friendly production processes and formulations. This includes sourcing renewable raw materials, reducing energy consumption during manufacturing, and developing products that contribute to the sustainability of construction projects. By prioritizing environmental considerations, manufacturers enhance their marketability and align with the growing demand for greener construction solutions.

In addition to construction applications, redispersible polymer powders find uses in a range of other industries, such as coatings, adhesives, and automotive sectors. The adaptability of these powders makes them a valuable resource for manufacturers in various fields. As technology advances, the market is likely to see further innovations in polymer powder formulations, enhancing performance while reducing environmental impact.

In conclusion, redispersible polymer powder manufacturers play a crucial role in the construction industry and beyond. By prioritizing quality, innovation, and sustainability, these manufacturers contribute to the development of advanced materials that improve performance, durability, and environmental responsibility in construction practices. As awareness of these benefits grows, the demand for high-quality RPP is expected to continue its upward trajectory, driving further advancements in this essential industry.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025