Nov . 11, 2024 21:49 Back to list

redispersible latex powder

Understanding Redispersible Latex Powder A Comprehensive Overview

Redispersible latex powder (RDP) is an innovative material widely used in various industries, particularly in construction, adhesives, paints, and coatings. It plays a crucial role in enhancing the performance of construction materials, making it a valuable component in modern building and renovation practices. This article explores the composition, properties, applications, and advantages of redispersible latex powder, shedding light on its importance in contemporary formulations.

What is Redispersible Latex Powder?

Redispersible latex powder is a fine white powder that is created by the spray-drying of polymer emulsions. It consists of polymers that, when mixed with water, can be redispersed to form a stable emulsion. This capability allows RDP to improve the adhesion, flexibility, and durability of various substrates in applications such as cement-based products, tile adhesives, and finishing coats.

The main types of polymers used in RDP include vinyl acetate ethylene (VAE), styrene-butadiene (SB), and acrylics, among others. The choice of polymer significantly impacts the properties of the final product, making it essential to select the appropriate type for specific applications.

Properties of Redispersible Latex Powder

RDP is characterized by several key properties that contribute to its effectiveness in various applications

1. Adhesion RDP enhances the bonding strength of materials, making it ideal for applications where strong adhesion is required, such as in tile adhesives and thin-set mortars.

2. Flexibility The incorporation of RDP into formulations imparts flexibility to the hardened products, allowing them to withstand thermal expansion and contraction without cracking.

3. Water Resistance Many redispersible latex powders provide excellent water resistance, making them suitable for external applications and areas with high humidity.

4. Durability RDP contributes to the overall durability of the products, improving resistance to weathering, UV radiation, and mechanical stress.

5. Workability The addition of RDP improves the workability of mixtures, allowing for easier application and enhanced performance during installation.

Applications of Redispersible Latex Powder

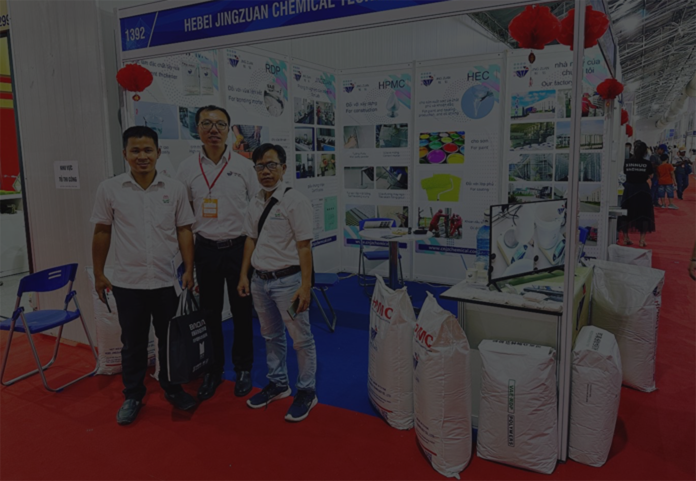

redispersible latex powder

The versatility of redispersible latex powder makes it applicable in a wide range of formulations

- Cement-Based Products RDP is commonly used in cement and mortar formulations to improve adhesion, flexibility, and water resistance. It is particularly beneficial in products such as tile adhesives, grout, and plaster.

- Paints and Coatings In the paint industry, RDP is utilized to enhance the performance of coatings, providing better adhesion to surfaces and improving the durability of the paint film.

- Adhesives RDP is used in various adhesive formulations, improving the bonding strength and flexibility of the final product, ensuring reliable performance in different environments.

- Self-Leveling Compounds The addition of RDP in self-leveling formulations ensures better flowability and adhesion, making it easier to achieve a smooth and level surface.

Advantages of Using Redispersible Latex Powder

Incorporating redispersible latex powder into formulations offers numerous advantages

1. Cost-Effectiveness RDP can enhance the performance of products while potentially reducing the need for additional expensive additives, leading to cost savings in formulation.

2. Sustainability Many manufacturers produce environmentally friendly RDP options, allowing companies to offer sustainable products that meet consumer demand for green building practices.

3. Enhanced Product Performance The properties imparted by RDP lead to the production of superior quality products that perform better in various conditions, satisfying customer expectations.

4. Customization The versatility of RDP allows for formulations tailored to specific application requirements, enabling manufacturers to create specialized products for their target markets.

Conclusion

Redispersible latex powder is a vital component in modern construction and manufacturing, significantly enhancing the performance of various materials. Its unique properties and versatility make it an invaluable addition to a wide range of applications, from construction to coatings. As industries continue to evolve, the role of RDP will undoubtedly expand, offering opportunities for innovations that prioritize efficiency, sustainability, and high-quality outcomes. Understanding and utilizing RDP can lead to the development of advanced materials that meet the demands of both current and future markets.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025