Sep . 28, 2025 03:35 Back to list

Redispersible Powder (RDP)-Hebei Jingzuan|Bonding Strength,Durability

Introduction to Redispersible Powder (RDP)

Redispersible Powder (RDP), also known as redispersible polymer powder, is a revolutionary additive in the construction industry. This versatile material is designed to enhance the properties of cement-based mortars, wall putty, and other construction coatings. By improving bonding strength, workability, and durability, RDP has become an essential component in modern construction practices. This article explores the technical specifications, applications, quality assurance methods, and the company background behind this innovative product.

Image 1: Redispersible Powder (RDP) in its raw form, highlighting its fine powder texture.

Product Overview

Redispersible Powder (RDP) is a polymer-based additive that, when mixed with water, reconstitutes into a polymer dispersion. This unique property allows it to act as a bonding agent and film-forming material in construction applications. Its molecular structure, represented by the formula (C₂H₄)ₓ(C₄H₆O₂)ᵧ, ensures compatibility with cementitious systems while providing exceptional performance characteristics.

Key benefits of RDP include:

- Enhanced Adhesion: Improves the bonding strength between mortar and substrates, reducing the risk of delamination.

- Crack Resistance: Minimizes cracking in coatings and mortars, ensuring long-term structural integrity.

- Improved Workability: Enhances the spreadability and coating efficiency of construction materials.

- Increased Strength: Boosts the mechanical strength of cement-based systems, making them more durable.

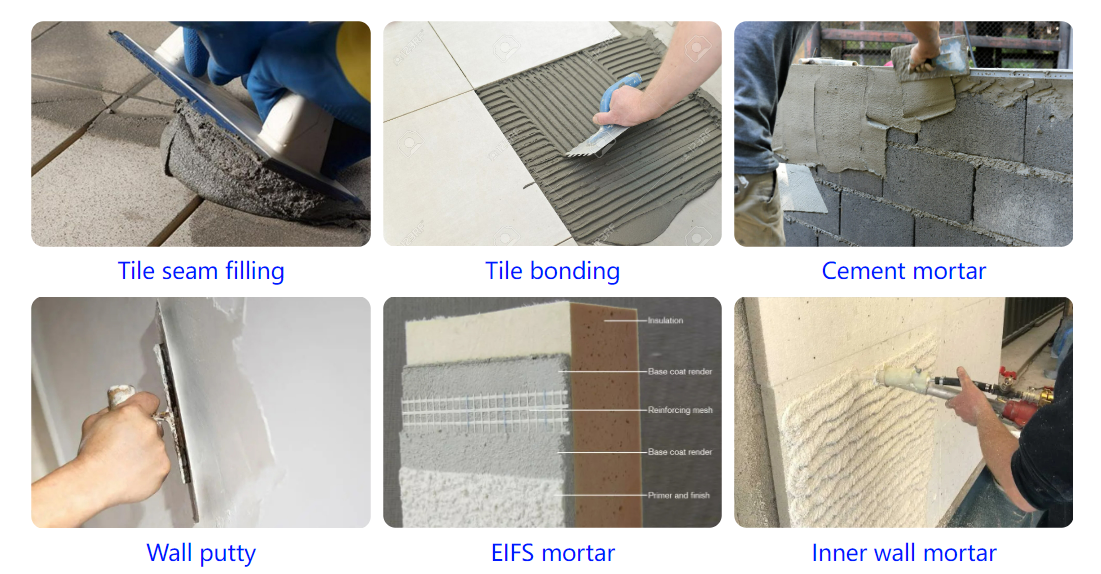

RDP is widely used in cement mortar, wall putty, EIFS (Exterior Insulation and Finish Systems) mortar, tile bonding mortar, and tile joint fillers. Its ability to penetrate and adhere to surfaces makes it a preferred choice for both interior and exterior applications.

Image 2: Quality check process for RDP polymer, demonstrating its bonding ability on a tile surface.

Technical Specifications

The following table summarizes the technical specifications of Redispersible Powder (RDP):

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C₂H₄)ₓ(C₄H₆O₂)ᵧ |

| Moisture Content (%) | ≤5 |

| Residue (Ash) (%) | 12-25 |

| Fineness (Mesh) | 80-120 |

| Minimum Film-Forming Temperature (°C) | 0-5 |

These specifications ensure that RDP meets the stringent requirements of construction materials, offering a balance between processability and performance. For detailed technical data, visit the RDP Product Page.

Applications in Construction

Redispersible Powder (RDP) is a critical component in various construction applications due to its ability to enhance material properties. Key applications include:

- Cement Mortar: RDP improves the adhesion and flexibility of cement-based mortars, making them suitable for high-stress environments.

- Wall Putty: It increases the coating efficiency and durability of wall putty, reducing the need for frequent repairs.

- EIFS Mortar: RDP ensures strong adhesion between insulation boards and substrates, enhancing the thermal performance of buildings.

- Tile Bonding Mortar: Its high bonding strength prevents tiles from loosening, even in humid or high-traffic areas.

- Tile Joint Filler: RDP improves the elasticity of grout, reducing cracks and maintaining a seamless finish.

The versatility of RDP makes it an ideal solution for both residential and commercial construction projects. For more information on its applications, explore the RDP Application Guide.

Image 3: Application of VAE (Vinyl Acetate-Ethylene) in construction materials, showcasing RDP's compatibility with polymer systems.

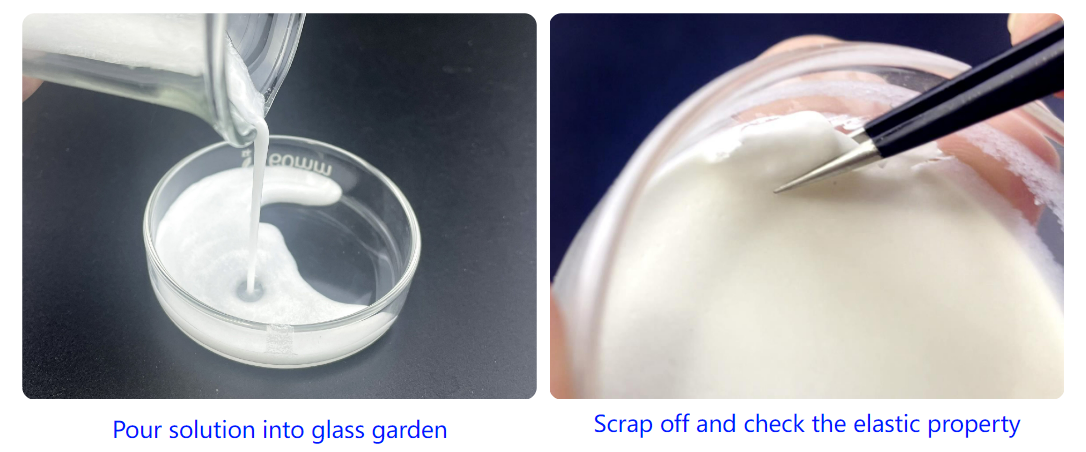

Quality Assurance: Simple Methods to Check RDP Quality

Ensuring the quality of Redispersible Powder (RDP) is crucial for its performance in construction applications. The following methods are commonly used to evaluate its properties:

Method 1: Bonding Ability Check

To test the bonding strength of RDP:

- Prepare a small amount of RDP solution.

- Pour it onto a clean tile surface and allow it to dry completely.

- If the RDP forms a hard, adherent film that is difficult to scrape off, it is considered qualified. This indicates that the VAE (Vinyl Acetate-Ethylene) component has successfully penetrated the tile surface.

Image 4: Visual demonstration of RDP's bonding ability on a tile surface.

Method 2: Film Formation and Dispersibility Check

To assess the film-forming and dispersibility properties of RDP:

- Create a small amount of RDP solution and pour it into a glass container111.

- Allow the solution to dry, forming a smooth, even film.

- Once dry, tear the film from the bottom and stretch it. A high-quality RDP should produce an elastic, tensile film.

Image 5: RDP solution forming a film on a glass surface, demonstrating its dispersibility.

A video demonstration of these quality checks is available for further reference.

Free Samples and Quality Assurance

Before placing a bulk order, customers are encouraged to request free samples to evaluate the quality of RDP. The supplier offers free samples with the buyer covering the air shipping cost. Additionally, samples from different batches can be provided to ensure consistent quality and stability.

For more details on sample availability, visit the RDP Product Page.

Image 6: Sample packaging for Redispersible Powder, emphasizing the company's commitment to quality.

Company Background: Hebei Jingzuan Chemical Technology Co., Ltd.

Hebei Jingzuan Chemical Technology Co., Ltd. (HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD.) is a leading manufacturer of high-performance chemical products, including Redispersible Powder (RDP) and VAE (Vinyl Acetate-Ethylene) powders. With a focus on innovation and quality, the company has established itself as a trusted supplier in the construction industry.

Key aspects of the company include:

- Expertise: Specialized in developing polymer-based additives for construction materials.

- Quality Control: Rigorous testing processes to ensure product consistency and performance.

- Global Reach: Exporting products to international markets, supporting construction projects worldwide.

For more information about the company, visit the Hebei Jingzuan Chemical Technology Website.

Image 7: Packaging of RDP products, reflecting the company's attention to detail and quality.

Conclusion

Redispersible Powder (RDP) is a game-changer in the construction industry, offering unmatched performance in bonding, durability, and workability. Its ability to enhance the properties of cement-based materials makes it an indispensable component in modern construction practices. With rigorous quality checks and a commitment to innovation, Hebei Jingzuan Chemical Technology Co., Ltd. continues to lead the way in providing high-quality RDP solutions.

For further details, visit the RDP Product Page or contact the company directly to request samples and technical support.

References

While this article focuses on the technical aspects of Redispersible Powder (RDP), it is important to note that standards and guidelines for construction materials are often established by organizations like the National Institute of Standards and Technology (NIST). Although the direct link to NIST's specific standards for RDP could not be retrieved, NIST's role in developing measurement standards for construction materials is critical for ensuring product quality and performance.

Reference: National Institute of Standards and Technology (NIST)

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025