Oct . 07, 2025 07:30 Back to list

Redispersible Powder (RDP): Enhancing Construction with Advanced Adhesive Technology - HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD.

Redispersible Powder (RDP), also known as redispersible polymer powder, is a revolutionary additive in the construction industry. Developed by HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD., this product is designed to enhance the performance of cement mortars, wall putty, and various construction materials. With its exceptional bonding properties and versatility, RDP has become a critical component in modern construction practices. This article explores the features, advantages, technical specifications, application scenarios, and company background of RDP, supported by authoritative references and practical insights.

What is Redispersible Powder?

Redispersible powder is a polymer-based additive that improves the adhesion, workability, and durability of construction materials. When mixed with water, it forms a stable emulsion that enhances the bonding strength of mortars and coatings. This technology is particularly valuable in applications where high-performance adhesion is required, such as in tile bonding mortar and EIFS (Exterior Insulation and Finish System) mortar. According to the National Institute of Standards and Technology (NIST), polymer-modified mortars have demonstrated significant improvements in mechanical properties and long-term durability.

Key Features and Advantages

RDP offers a range of benefits that make it indispensable in construction projects. Its primary advantages include:

- Enhanced Bonding Ability: RDP significantly improves the adhesion of mortars and coatings to substrates, reducing the risk of delamination and cracking.

- Improved Workability: The polymer content enhances the spreadability and coating rate of construction materials, making them easier to apply.

- Crack Resistance: By increasing the flexibility of the mortar, RDP helps prevent micro-cracks caused by thermal expansion and contraction.

- Strength Enhancement: RDP contributes to the overall structural integrity of buildings by boosting the compressive and tensile strength of mortars.

These features make RDP an ideal solution for both residential and commercial construction projects. For a deeper understanding of polymer-based construction materials, refer to the NIST Standards and Technology Database.

Technical Specifications

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C₂H₄)ₓ(C₄H₆O₂)ᵧ |

| Moisture Content (%) | ≤5 |

| Residue (Ash) (%) | 12-25 |

| Fineness (Mesh) | 80-120 |

| Minimum Film-Forming Temperature (℃) | 0-5 |

| Date | 2019-09-18 |

Application Scenarios

RDP is widely used in the following construction applications:

- Cement Mortar: Enhances adhesion and durability in concrete structures.

- Wall Putty: Improves the smoothness and adhesion of wall coatings.

- EIFS Mortar: Provides flexibility and resistance to weathering.

- Tile Bonding Mortar: Ensures strong adhesion of tiles to surfaces.

- Tile Seam Filling: Prevents cracking and improves water resistance.

For more information on construction material standards, visit the NIST Construction Materials Research Page.

Quality Assurance Methods

To ensure the quality of RDP, the following methods are recommended:

Method No. 1: Bonding Ability Check

Prepare a small amount of RDP solution and apply it to a clean tile surface. After drying, a VAE (Vinyl Acetate-Ethylene) film should form. If the film is hard to scrape off, the product is qualified. This test verifies the polymer's ability to adhere to surfaces, as noted in NIST research on polymer adhesion.

Method No. 2: Film Formation and Dispersibility Check

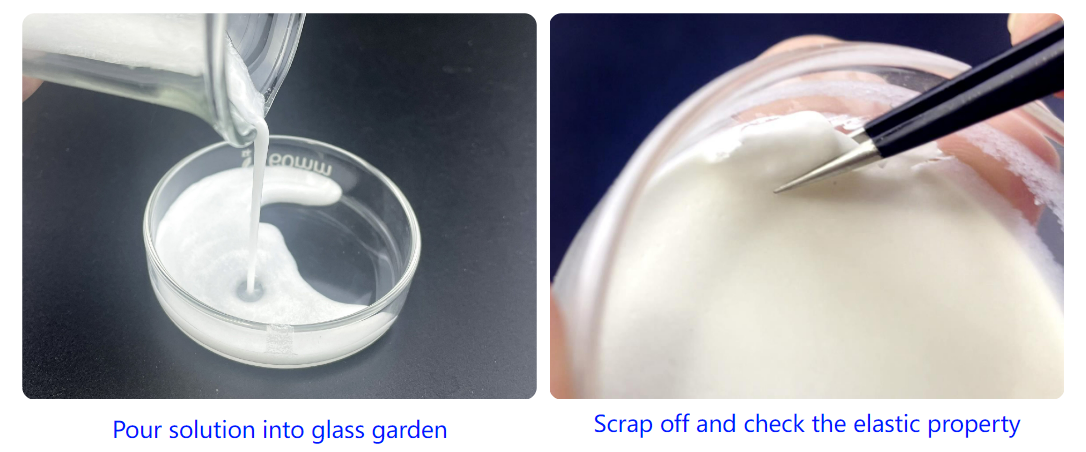

Prepare an RDP solution and pour it into a glass container111. After drying, the solution should form a smooth, elastic film. The film should be stretchable and tear-resistant, indicating proper dispersibility. This method ensures the polymer's ability to re-disperse in water, a critical factor for its performance in construction applications.

For a visual guide, watch the RDP Quality Check Video.

Free Samples and Customization

HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD. offers free samples to potential customers, allowing them to test the product's quality before placing a bulk order. The company also provides samples from different batches to ensure consistent performance. This approach aligns with industry standards for quality control, as highlighted by NIST's guidelines on material testing.

Packaging and Shipping

RDP is packaged in airtight container111s to maintain its stability and prevent moisture absorption. The company offers flexible shipping options, including air freight, to accommodate customer needs. The packaging design ensures the product remains intact during transit, as demonstrated in the images below:

About HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD.

HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD. is a leading manufacturer of construction chemicals, specializing in the production of redispersible powder and VAE powder. With over a decade of experience, the company has established itself as a trusted supplier in the global market. Their commitment to quality and innovation ensures that their products meet the highest industry standards. For more information, visit the HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD. Product Page.

Conclusion

Redispersible Powder (RDP) is a game-changer in the construction industry, offering unparalleled bonding strength, workability, and durability. Its applications span across various construction materials, making it an essential component for modern building projects. By adhering to strict quality control measures and leveraging advanced polymer technology, HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD. continues to set benchmarks in the industry. For further details, explore the NIST Research on Polymer-Based Construction Materials.

References

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025