Sep . 28, 2025 13:25 Back to list

Redispersible Powder - Hebei Jingzuan|Bonding Strength&Anti-Cracking Properties

Introduction to Redispersible Powder (RDP)

Redispersible powder, commonly referred to as RDP, is a specialized additive used extensively in the construction industry. This innovative material is designed to improve the properties of cement mortars, wall putty, and various other construction compounds. Its unique ability to redisperse in water upon mixing makes it an essential component for enhancing bonding strength, workability, and durability in construction applications. Learn more about RDP.

Key Features and Benefits of RDP

RDP is renowned for its exceptional bonding capabilities, which significantly improve the adhesion of mortars and putties to surfaces. This makes it ideal for applications such as tile bonding mortar, EIFS mortar, and inner wall mortar. The addition of RDP enhances the coating and spreading rate of construction materials, ensuring a more uniform application. Furthermore, it contributes to the anti-cracking properties of structures, thereby increasing their overall strength and longevity.

One of the standout features of RDP is its redispersibility—a property that allows it to reconstitute into a stable dispersion when mixed with water. This characteristic is crucial for maintaining the integrity of construction materials during storage and transportation. The VAE (Vinyl Acetate-Ethylene) content in RDP plays a vital role in this process, as it forms a durable film that adheres strongly to surfaces upon drying.

Quality Assurance: Testing Methods for RDP

Ensuring the quality of RDP is critical for its performance in construction applications. Two primary methods are used to evaluate its quality:

Method No. 1: Bonding Ability Check

To test the bonding ability of RDP, a small amount of the solution is applied to a clean tile surface and allowed to dry. A VAE film should form on the surface, which should be difficult to scrape off. This indicates that the VAE has successfully penetrated the tile surface, ensuring strong adhesion.

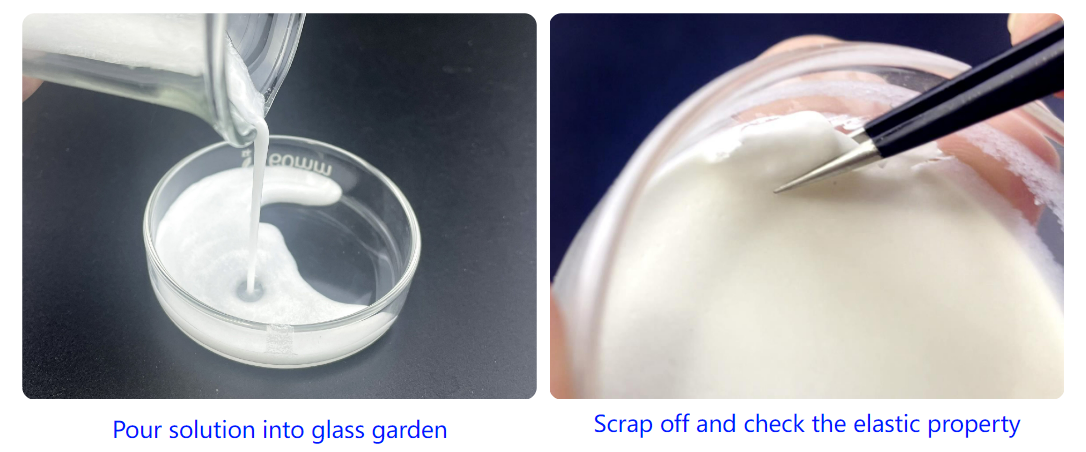

Method No. 2: Film and Dispersibility Check

This method involves creating a small amount of RDP solution and pouring it into a glass dish. After drying, the resulting film should be smooth, even, and elastic. When torn from the bottom and stretched, the film should exhibit tensile strength, confirming its dispersibility and quality.

A video demonstration of these tests is available to provide a clearer understanding of the quality assurance process.

Free Samples and Quality Stability

Before placing a bulk order, customers are encouraged to check the quality of RDP using free samples. The supplier offers free samples with the buyer covering the air shipping cost. This allows clients to evaluate the product's performance and ensure it meets their specific requirements. Additionally, samples from different batches are provided to assess the quality stability of the product.

Applications of RDP in Construction

RDP is a versatile additive with a wide range of applications in the construction industry. It is commonly used in the following areas:

- Cement Mortar: Enhances bonding strength and workability.

- Wall Putty: Improves coating and spreading properties.

- EIFS Mortar: Provides excellent adhesion and durability.

- Tile Bonding Mortar: Ensures strong adhesion to surfaces.

- Tile Seam Filling: Offers superior anti-cracking properties.

The anti-cracking and strength-enhancing properties of RDP make it an indispensable component in modern construction practices. For more information on its applications, visit RDP Product Page.

Technical Specifications of RDP

The technical specifications of RDP are crucial for understanding its performance characteristics. Below is a detailed table outlining the key parameters:

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C₂H₄)ₓ(C₄H₆O₂)ᵧ |

| Moisture Content (%) | ≤5 |

| Residue (Ash) (%) | 12-25 |

| Fineness (Mesh) | 80-120 |

| Minimum Film-forming Temperature (°C) | 0-5 |

These specifications highlight the high-quality standards of RDP, ensuring its effectiveness in various construction scenarios. For detailed technical data, refer to the RDP Technical Specifications.

Company Background: Hebei Jingzuan Chemical Technology Co., Ltd.

Hebei Jingzuan Chemical Technology Co., Ltd. (HEBEI JINGZUAN CHEMICAL TECHNOLOGY CO., LTD.) is a leading manufacturer of chemical products, specializing in the production of RDP and other construction additives. With a commitment to quality and innovation, the company has established itself as a reliable supplier in the global market. Their expertise in chemical formulations ensures that their products meet the highest industry standards.

For more information about the company, visit Hebei Jingzuan Chemical Technology Co., Ltd..

Conclusion: The Role of RDP in Modern Construction

RDP plays a pivotal role in enhancing the performance of construction materials. Its superior bonding ability, anti-cracking properties, and versatile applications make it an essential component in modern construction practices. As highlighted by NIST (National Institute of Standards and Technology), the importance of precise measurements and standardized testing in the construction industry cannot be overstated. The quality assurance methods for RDP align with these principles, ensuring that the product meets the required performance standards.

For further information on RDP and its applications, visit RDP Product Page.

References

NIST (National Institute of Standards and Technology) provides critical standards and research that support the construction industry. For more information on NIST's role in construction standards, visit their official website.

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025