Sep . 30, 2025 07:30 Back to list

Redispersible Powder-Hebei Jingzuan Chemical|Enhancing Construction Performance&Improving Material Durability

Redispersible Powder (RDP), also known as Redispersible Powder, is a revolutionary additive in the construction industry. Developed by Hebei Jingzuan Chemical Technology Co., Ltd., this innovative product enhances the performance of cement mortars, wall putty, and other construction materials. This article explores the features, advantages, technical specifications, and applications of RDP, while also highlighting the company's commitment to quality and innovation.

Understanding Redispersible Powder

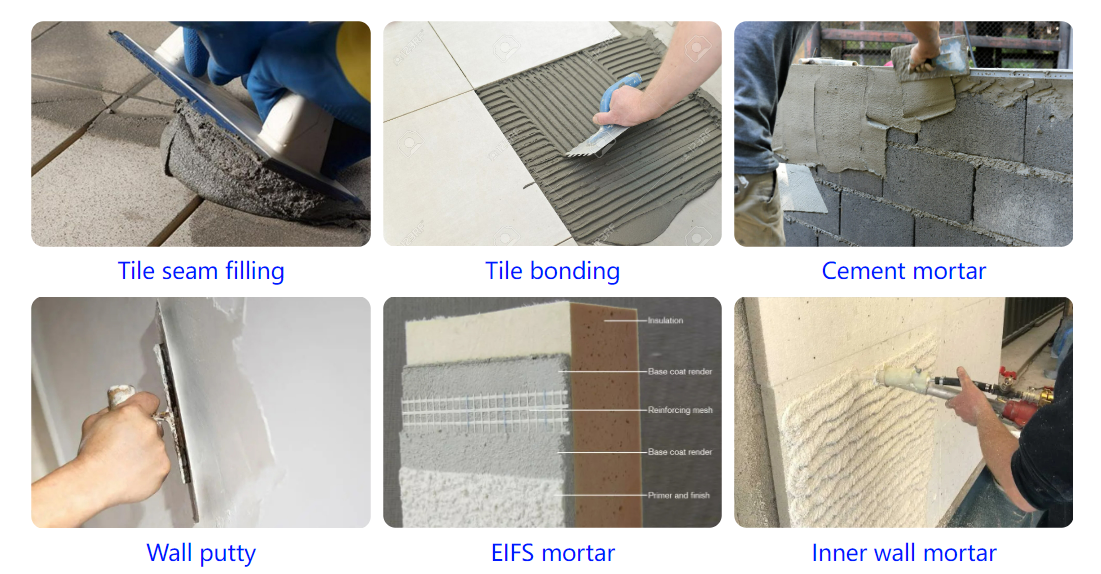

Redispersible Powder is a fine, white powder that, when mixed with water, reconstitutes into a stable emulsion. This unique property makes it an essential component in various construction applications. The chemical formula of RDP is (C2H4)x(C4H6O2)y, which contributes to its excellent bonding and dispersibility characteristics. RDP is widely used in cement mortar, wall putty, EIFS mortar, inner wall mortar, tile bonding mortar, and tile seam filling. Its ability to improve the bonding strength and workability of these materials has made it a preferred choice among construction professionals.

Key Features and Advantages

Redispersible Powder offers several advantages that make it a valuable addition to construction materials. One of its primary benefits is its exceptional bonding ability. When incorporated into mortar or putty, RDP enhances the adhesion between the material and the surface, reducing the risk of cracking and improving the overall durability of the structure. Additionally, RDP improves the coating and spreading rate of the mixture, making it easier to apply and ensuring a more uniform finish.

Another significant advantage of RDP is its ability to enhance the strength of construction materials. By improving the cohesion of the mixture, RDP helps to prevent cracking and increase the load-bearing capacity of the structure. This makes it ideal for use in high-stress applications such as tile bonding and wall putty. Furthermore, RDP's water retention properties ensure that the mixture remains workable for a longer period, reducing the risk of premature drying and improving the overall quality of the finished product.

Technical Specifications

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C2H4)x(C4H6O2)y |

| Moisture (%) | ≤5 |

| Residue (Ash) (%) | 12-25 |

| Fineness (mesh) | 80-120 |

| Min Film-forming Temperature (°C) | 0-5 |

The technical specifications of Redispersible Powder highlight its high quality and performance. With a moisture content of ≤5%, RDP ensures that the mixture remains stable and workable. The residue (ash) content of 12-25% contributes to the strength and durability of the final product. The fineness of 80-120 mesh ensures that the powder disperses evenly in the mixture, while the low minimum film-forming temperature of 0-5°C allows for effective application in a wide range of environmental conditions.

Applications in Construction

Redispersible Powder is used in a variety of construction applications, including cement mortar, wall putty, EIFS mortar, inner wall mortar, tile bonding mortar, and tile seam filling. In cement mortar, RDP improves the bonding strength and workability, making it easier to apply and ensuring a more durable finish. For wall putty, RDP enhances the adhesion of the putty to the surface, reducing the risk of cracking and peeling. In EIFS mortar, RDP helps to create a smooth and even finish, while in tile bonding mortar, it ensures a strong bond between the tiles and the surface.

One of the most significant applications of RDP is in tile bonding and seam filling. The exceptional bonding ability of RDP ensures that tiles remain securely in place, even under heavy use. Additionally, RDP's ability to improve the spreading rate of the mortar makes it easier to apply, reducing the time and effort required for installation. This makes RDP an ideal choice for both residential and commercial construction projects.

Quality Assurance and Testing Methods

Ensuring the quality of Redispersible Powder is crucial for its performance in construction applications. The following methods are commonly used to check the quality of RDP:

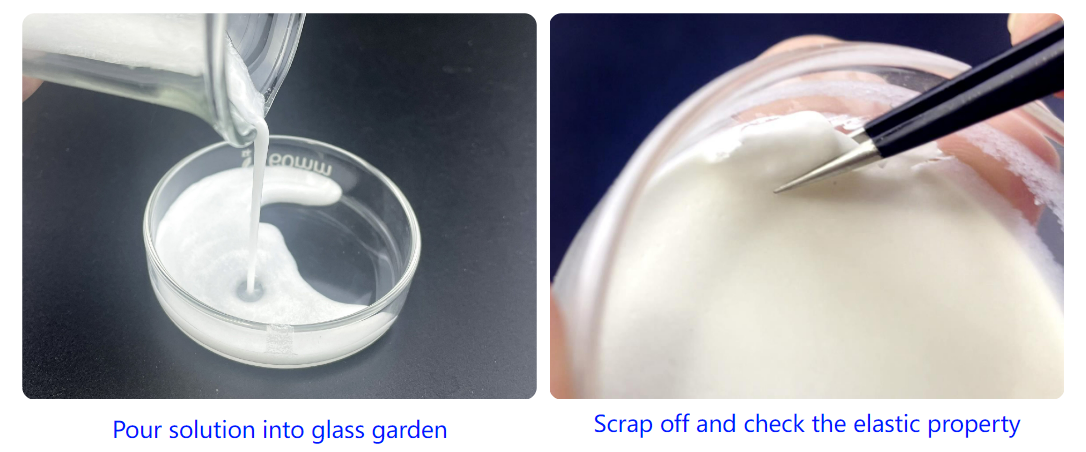

Method No. 1: Bonding Ability Checking

To test the bonding ability of RDP, a small amount of the solution is poured onto a clean tile surface and allowed to dry. A film of VAE (Vinyl Acetate-Ethylene) should remain on the surface, and if it is difficult to scrape off, the RDP is considered qualified. VAE penetrates the tile surface when dried, ensuring a strong bond.

Method No. 2: Film and Dispersibility Checking

To check the film-forming and dispersibility properties of RDP, a small amount of the solution is poured into a glass dish and allowed to dry. A smooth, even film should form, and when torn off, it should be elastic and tensile. This test ensures that the RDP can effectively disperse and form a stable film in the mixture.

For a visual demonstration of these quality checks, refer to the video below:

Free Samples and Quality Stability

Before placing a bulk order, Hebei Jingzuan Chemical Technology Co., Ltd. recommends checking the quality of RDP through free samples. The company provides free samples with the air shipping cost covered by the buyer. This allows customers to evaluate the product's performance and ensure it meets their requirements. Additionally, the company offers samples from different batches to assess the quality stability of RDP, ensuring consistent performance across all shipments.

Company Background: Hebei Jingzuan Chemical Technology Co., Ltd.

Founded in 2019, Hebei Jingzuan Chemical Technology Co., Ltd. is a leading manufacturer of high-quality chemical products, including Redispersible Powder and VAE Powder. The company is committed to innovation, quality, and customer satisfaction, providing reliable solutions for the construction industry. With a focus on research and development, Hebei Jingzuan Chemical Technology Co., Ltd. continues to set new standards in the chemical manufacturing sector.

Package and Shipping

Redispersible Powder is available in various packaging options to meet the needs of different customers. The company ensures that the product is securely packaged to prevent damage during transportation. Shipping options include air and sea freight, with the company providing detailed guidance to ensure timely delivery.

Authoritative Citations and References

According to the National Institute of Standards and Technology (NIST), the development of high-performance construction materials is critical for ensuring the safety and durability of structures. NIST's research on cement and mortar testing methods highlights the importance of additives like RDP in improving the mechanical properties of construction materials. For more information, refer to the NIST publication on Standard Reference Materials.

References:

Hebei Jingzuan Chemical Technology Co., Ltd. continues to lead the way in providing innovative solutions for the construction industry. With a commitment to quality and customer satisfaction, the company ensures that its products meet the highest standards of performance and reliability.

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025