Oct . 01, 2025 01:30 Back to list

Redispersible Powder - Hebei Jingzuan Chemical | Construction Adhesive, Anti-Cracking, Strength Enhancement

Redispersible Powder (RDP) is a revolutionary construction additive that has transformed modern building practices. Developed by Hebei Jingzuan Chemical Technology Co., Ltd., RDP enhances the performance of cement mortars, wall putty, and other construction materials, offering superior bonding, durability, and flexibility. This article explores the features, advantages, technical specifications, and applications of RDP, along with insights into the company behind this innovative product.

Understanding Redispersible Powder (RDP)

Redispersible Powder (RDP) is a polymer-based additive designed to improve the workability, adhesion, and structural integrity of construction materials. Commonly referred to as RDP, it is widely used in cement mortar, wall putty, EIFS (Exterior Insulation and Finish Systems) mortar, and tile bonding applications. The key to RDP's effectiveness lies in its ability to re-disperse in water, forming a stable film that enhances the mechanical properties of construction materials.

Key Features of RDP

- Exceptional Bonding Ability: RDP significantly improves the adhesion of mortars and putty to surfaces, ensuring long-lasting results.

- Anti-Cracking Properties: It reduces the risk of cracks in finished surfaces, contributing to structural stability.

- Enhanced Strength: RDP increases the compressive and tensile strength of construction materials, making them more resilient.

- Improved Workability: It enhances the coating and spreading rate of mortars, making application more efficient.

Advantages of Using RDP in Construction

Redispersible Powder offers numerous benefits that make it a preferred choice in the construction industry. One of its primary advantages is its ability to enhance bonding strength, which is critical for applications like tile bonding and wall putty. This ensures that materials adhere firmly to surfaces, reducing the likelihood of detachment or delamination over time.

Another significant advantage is its anti-cracking properties. By incorporating RDP into mortars and putty, construction professionals can minimize the formation of cracks caused by thermal expansion, contraction, or structural stress. This is particularly important in regions with extreme weather conditions, where materials are subjected to frequent temperature fluctuations.

RDP also boosts the mechanical strength of construction materials. The polymer film formed by RDP acts as a reinforcing agent, increasing the durability of cement-based products. This makes RDP ideal for applications where high load-bearing capacity is required, such as in EIFS systems or industrial flooring.

Additionally, RDP improves the workability of mortars and putty. Its ability to enhance the coating and spreading rate allows for smoother and more uniform application, reducing labor time and material waste. This efficiency is especially valuable in large-scale construction projects where productivity is a key concern.

Technical Specifications of RDP

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C₂H₄)ₓ(C₄H₆O₂)ᵧ |

| Moisture (%) | ≤5 |

| Residue (Ash) (%) | 12-25 |

| Fineness (Mesh) | 80-120 |

| Min Film-forming Temperature (°C) | 0-5 |

Application Scenarios of RDP

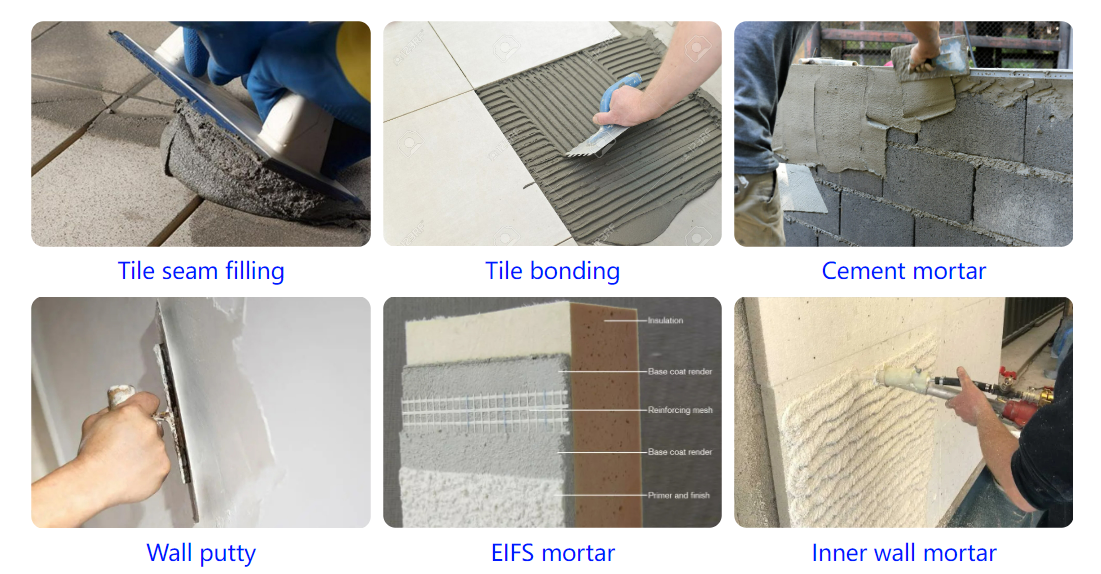

Redispersible Powder is a versatile additive with a wide range of applications in the construction industry. Its primary uses include:

- Cement Mortar: RDP enhances the bonding strength and workability of cement mortar, making it suitable for masonry and plastering applications.

- Wall Putty: It improves the adhesion of wall putty to surfaces, ensuring a smooth and durable finish.

- EIFS Mortar: RDP is used in Exterior Insulation and Finish Systems to provide thermal insulation and structural support.

- Tile Bonding Mortar: The high bonding ability of RDP ensures that tiles adhere firmly to substrates, reducing the risk of detachment.

- Tile Seam Filling: RDP enhances the flexibility and durability of tile joints, preventing cracks and water penetration.

Quality Assurance: How to Check RDP Quality

Ensuring the quality of Redispersible Powder is crucial for its performance in construction applications. Here are two simple methods to verify its quality:

Method 1: Bonding Ability Check

To test the bonding ability of RDP, create a small solution and pour it onto a clean tile surface. After it dries, a film of VAE (Vinyl Acetate-Ethylene) should remain on the tile. If the film is difficult to scrape off, it indicates high-quality RDP.

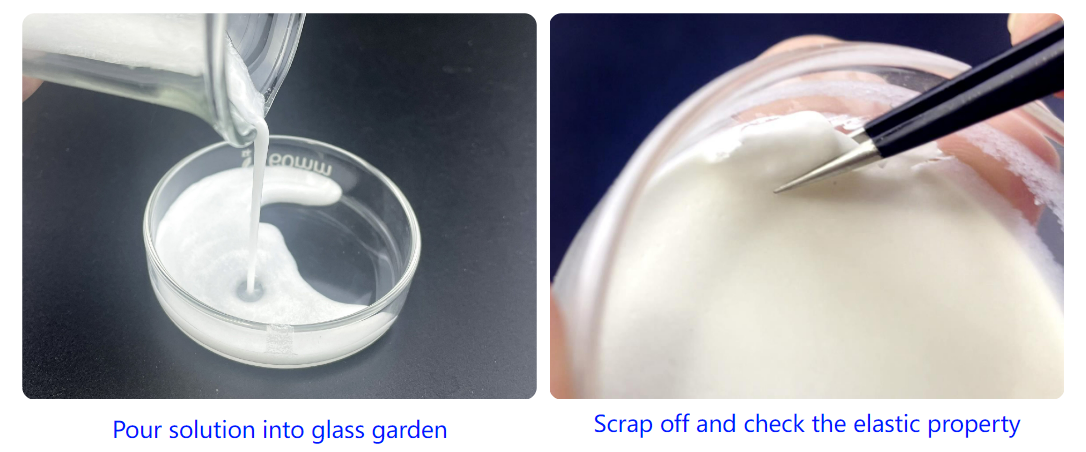

Method 2: Film Formation and Dispersibility Check

Prepare a small amount of RDP solution and pour it into a glass dish. Allow it to dry, forming a smooth film. When the film is stretched, it should exhibit elasticity and tensile strength.

For a visual demonstration of these tests, refer to the video tutorial.

Free Samples and Quality Stability

Hebei Jingzuan Chemical Technology Co., Ltd. offers free samples of RDP to potential customers. Before placing a bulk order, it is recommended to test the quality with samples. The company covers the air shipping cost, and samples from different batches are available to ensure quality consistency.

VAE Application in RDP

Vinyl Acetate-Ethylene (VAE) is a critical component of RDP, contributing to its film-forming properties. VAE ensures that RDP adheres effectively to surfaces, enhancing the durability of construction materials.

Package and Shipping

RDP is available in various packaging options to suit different needs. The product is shipped in standard container111s, ensuring safe and efficient delivery.

About Hebei Jingzuan Chemical Technology Co., Ltd.

Hebei Jingzuan Chemical Technology Co., Ltd. is a leading manufacturer of construction chemicals, specializing in the production of Redispersible Powder (RDP) and other polymer-based additives. With over a decade of experience in the industry, the company is committed to delivering high-quality products that meet international standards. Their state-of-the-art facilities and rigorous quality control processes ensure that every batch of RDP meets the highest performance criteria.

Authoritative Citations and References

While specific NIST standards for RDP were not found during the search, the technical specifications of RDP align with general industry standards for construction chemicals. For further information on material testing and quality assurance, refer to the National Institute of Standards and Technology (NIST). Although no direct citations were found for RDP, the principles of material testing and quality control outlined by NIST provide a framework for evaluating the performance of construction additives.

References:

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025