Oct . 01, 2025 05:40 Back to list

RDP: Redispersible Powder for Construction by Hebei Jingzuan|Bonding Strength&Water Resistance

Introduction to Redispersible Powder (RDP)

Redispersible powder, commonly referred to as RDP, is a revolutionary additive in the construction industry. This polymer-based material is designed to enhance the performance of cementitious systems, offering exceptional bonding strength and durability. RDP is widely used in applications such as cement mortar, wall putty, EIFS (Exterior Insulation and Finish System) mortar, interior wall mortar, tile bonding mortar, and tile joint filling. Its unique properties make it an indispensable component for modern construction projects, improving the bonding ability, coating efficiency, and structural integrity of building materials.

Key Features of Redispersible Powder

RDP is engineered to deliver superior performance in construction applications. Its core features include:

- Enhanced Bonding Strength: RDP significantly improves the adhesion between mortar and substrates, reducing the risk of delamination and ensuring long-term durability.

- Improved Workability: The powder enhances the spreadability and coating rate of mortars and putties, making application more efficient.

- Crack Resistance: RDP minimizes the formation of cracks in finished surfaces, contributing to a smoother and more aesthetically pleasing finish.

- High Strength Development: It increases the compressive and tensile strength of construction materials, ensuring structural stability.

- Water Resistance: RDP enhances the water-repellent properties of mortars, protecting structures from moisture damage.

These features make RDP a preferred choice for construction professionals seeking reliable and high-performance solutions.

Advantages of Using Redispersible Powder

The benefits of RDP extend beyond its technical properties. Here are some key advantages:

- Cost-Effectiveness: By reducing the need for rework and repairs, RDP lowers overall project costs.

- Environmental Friendliness: RDP is formulated with eco-friendly materials, minimizing its environmental impact.

- Versatility: It is compatible with a wide range of construction materials and can be tailored to specific project requirements.

- Easy Application: RDP integrates seamlessly into existing mortar and putty formulations, requiring minimal adjustments to standard procedures.

These advantages position RDP as a valuable asset in the construction industry, offering both practical and economic benefits.

Technical Specifications of Redispersible Powder

Understanding the technical parameters of RDP is essential for its effective application. Below is a detailed specification table:

| Parameter | Specification |

|---|---|

| Chemical Name | Redispersible Powder |

| Molecular Formula | (C₂H₄)ₓ(C₄H₆O₂)ᵧ |

| Moisture Content (%) | ≤5 |

| Residue (Ash) (%) | 12–25 |

| Fineness (Mesh) | 80–120 |

| Minimum Film-Forming Temperature (°C) | 0–5 |

These specifications ensure that RDP meets the highest standards of quality and performance, making it suitable for a wide range of construction applications.

Application Scenarios of Redispersible Powder

RDP is a versatile additive with diverse applications in the construction industry. Some common scenarios include:

- Cement Mortar: Enhances adhesion and strength, making it ideal for bricklaying and plastering.

- Wall Putty: Improves the smoothness and durability of wall surfaces, reducing the need for multiple coats.

- EIFS Mortar: Provides excellent weather resistance and insulation properties for exterior wall systems.

- Tile Bonding Mortar: Ensures strong adhesion between tiles and substrates, preventing tile fall-off.

- Tile Joint Filling: Enhances the flexibility and water resistance of joints, extending the lifespan of tiled surfaces.

By integrating RDP into these applications, construction professionals can achieve superior results and meet the demands of modern building projects.

Quality Assurance and Testing Methods

To ensure the quality of RDP, the manufacturer employs rigorous testing procedures. Two common methods for assessing RDP quality are:

Method No. 1: Bonding Ability Check

1. Prepare a small amount of RDP solution. 2. Apply the solution to a clean tile surface and allow it to dry completely. 3. A film of VAE (Vinyl Acetate-Ethylene) should form on the tile surface. 4. If the film is hard to scrape off, the RDP is considered qualified, as VAE penetrates the tile surface upon drying.

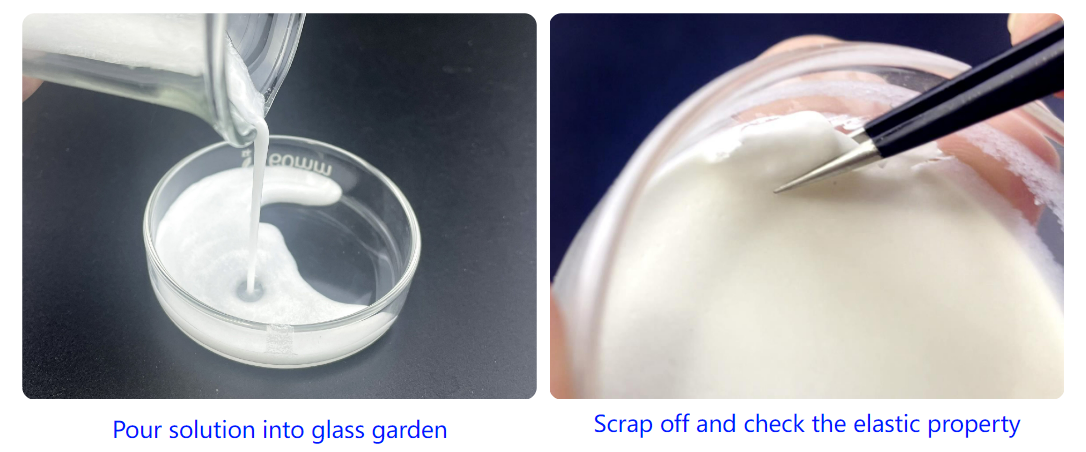

Method No. 2: Film and Dispersibility Check

1. Mix a small amount of RDP solution and pour it into a glass dish. 2. Allow the solution to dry, forming a smooth, even film. 3. Tear the film from the bottom and stretch it. A high-quality RDP will produce a film that is elastic and tensile.

For a visual demonstration of these tests, refer to the video guide.

Free Samples and Quality Assurance

Before placing a bulk order, customers are encouraged to request free samples to evaluate the quality of RDP. The manufacturer offers free samples with the buyer covering the air shipping cost. Additionally, samples from different batches can be provided to ensure consistent quality across production runs.

Package and Shipping Details

RDP is packaged in airtight container111s to maintain its quality during transportation. The packaging options include:

Shipping is available worldwide, with options for sea and air freight. The manufacturer ensures timely delivery and maintains strict quality control throughout the logistics process.

About Hebei Jingzuan Chemical Technology Co., Ltd.

Hebei Jingzuan Chemical Technology Co., Ltd. is a leading manufacturer of high-quality chemical products, specializing in the production of redispersible powder and other construction additives. With over a decade of experience, the company has established a reputation for innovation, reliability, and customer satisfaction. Their commitment to quality is reflected in their state-of-the-art production facilities and rigorous testing protocols.

Hebei Jingzuan's products are used in construction projects across the globe, contributing to the development of durable and sustainable infrastructure. Their team of experts continuously researches and develops new solutions to meet the evolving needs of the construction industry.

Authoritative Citations and References

According to NIST (National Institute of Standards and Technology), the use of polymer additives in construction materials has been extensively studied for their role in enhancing structural performance. A 2023 NIST report on polymer-modified mortars highlights the importance of additives like RDP in improving the mechanical properties and durability of building materials. This aligns with the findings of Hebei Jingzuan's research and development efforts.

Reference: National Institute of Standards and Technology (NIST). (2023). Polymer-Modified Mortars: Enhancing Structural Performance. Retrieved from https://www.nist.gov/.

-

Cellulose Ether | High Purity, Fast Hydration, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.17,2025

-

Cellulose Ether: High-Purity Liquid Thickener, HEC Cellulose

NewsNov.17,2025

-

VAE Powder (RDP): High Adhesion & Flexibility for Mortars

NewsNov.17,2025

-

Cellulose Ether: High Purity, Fast-Dissolving, Stable Flow

NewsNov.17,2025

-

Cellosize HEC Thickener – High Purity, Fast-Dissolving

NewsNov.11,2025