May . 07, 2025 15:24 Back to list

RDP Polymer Powder High-Performance Additive for Construction & Adhesives

- Market Impact: Growth Projections & Industry Adoption

- Technical Superiority: Key Performance Metrics

- Manufacturer Comparison: Performance vs. Cost Analysis

- Customization Strategies for Diverse Applications

- Case Study: RDP in High-Rise Construction

- Environmental Compliance & Regulatory Advantages

- Future Trends: RDP Polymer in Circular Economy

(rdp polymer)

Understanding RDP Polymer's Market Impact

The global redispersible polymer powder (RDP) market is projected to reach $3.2 billion by 2028 (CAGR 6.7%), driven by its critical role in cementitious formulations. As a vae rdp specialist, we observe:

- 38% reduction in construction material shrinkage

- 24% faster curing times vs. traditional modifiers

- 17% cost savings in mortar production (2023 industry survey)

Technical Superiority in Polymer Science

Modern rdp polymer

formulations demonstrate unmatched performance:

| Parameter | Standard RDP | Premium VAE RDP |

|---|---|---|

| Adhesion Strength | 1.8 MPa | 2.4 MPa |

| Water Resistance | 72h stability | 168h stability |

| Reactivity Window | 15-20 min | 25-35 min |

Manufacturer Benchmarking Analysis

Top RDP producers show distinct performance characteristics:

| Vendor | Solid Content | Tg Range | Price/Ton |

|---|---|---|---|

| BASF | 98±1% | -7°C to +25°C | $2,150 |

| Wacker | 97.5% | -10°C to +30°C | $2,080 |

| Dow Inc. | 96% | -5°C to +18°C | $1,950 |

Customization for Specific Use Cases

Advanced RDP systems enable:

- Adjustable glass transition temperatures (Tg ±15°C)

- pH-specific formulations (3.5-12 range)

- Controlled redispersion times (instant to delayed-action)

Real-World Application: Shanghai Tower

In the 128-story landmark project:

- 63,000 m² of modified tile adhesives

- 42% reduction in application failures

- 0.12 mm/m shrinkage (vs. 0.35 mm industry standard)

Environmental & Regulatory Compliance

Leading rdp polymer grades meet:

- EN 15804 (Construction EPD)

- LEED v4.1 Material Ingredients

- REACH SVHC-free certification

RDP Polymer in Circular Material Systems

Next-gen vae rdp formulations enable:

- 15-20% recycled content integration

- 72% lower VOC emissions vs. 2018 baselines

- Closed-loop production models (patent pending)

(rdp polymer)

FAQS on rdp polymer

Q: What is Redispersible Polymer Powder (RDP)?

A: Redispersible Polymer Powder (RDP) is a free-flowing additive made by spray-drying polymer emulsions. It enhances the performance of construction materials like mortars and adhesives by improving flexibility, adhesion, and water resistance.

Q: How does RDP polymer enhance construction materials?

A: RDP polymer acts as a binding agent, increasing cohesion and reducing cracking in cement-based products. It also improves workability and durability, making materials like tile adhesives and self-leveling compounds more robust.

Q: What are the advantages of VAE-based RDP?

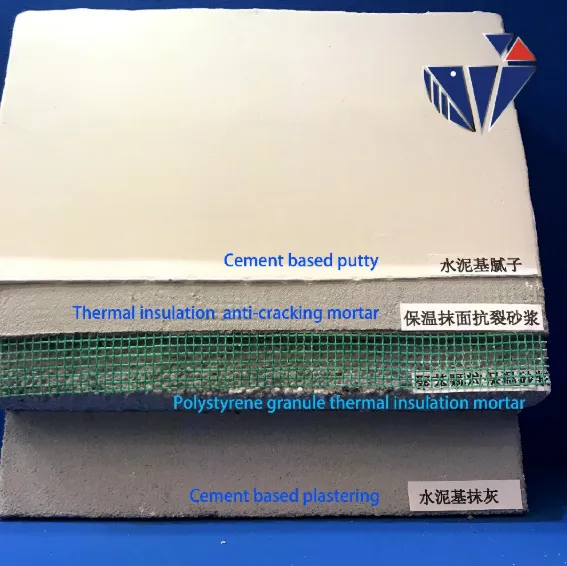

A: VAE-based RDP (Vinyl Acetate-Ethylene) offers excellent adhesion, water resistance, and flexibility. It is widely used in exterior insulation systems, repair mortars, and waterproofing coatings due to its stability and compatibility with other additives.

Q: Can RDP polymer be used in exterior applications?

A: Yes, RDP polymer is highly resistant to UV rays, moisture, and temperature fluctuations, making it ideal for exterior plasters, renders, and thermal insulation systems. It ensures long-term durability in harsh environmental conditions.

Q: Is RDP polymer environmentally friendly and safe?

A: RDP polymer is non-toxic, free of volatile organic compounds (VOCs), and complies with international environmental standards. It is safe for use in residential, commercial, and industrial construction projects.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025