Sep . 29, 2024 05:48 Back to list

Current Market Trends for Methyl Hydroxyethyl Cellulose Pricing Analysis

The Price of Methyl Hydroxyethyl Cellulose An Overview

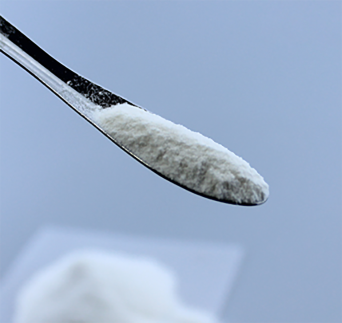

Methyl Hydroxyethyl Cellulose (MHEC) is a widely used non-ionic cellulose ether, recognized for its various applications across numerous industries, including construction, pharmaceuticals, food, and personal care. Its versatility stems from its ability to improve the texture, consistency, and stability of formulations. Given its importance, understanding the pricing dynamics of MHEC is crucial for manufacturers, suppliers, and end-users alike.

One of the primary factors influencing the price of MHEC is raw material costs. MHEC is derived from natural cellulose sources, typically wood pulp or cotton, which may be affected by fluctuations in global pulp prices. As the demand for sustainable and eco-friendly products increases, the sourcing of cellulose materials has become more competitive, impacting overall costs.

The Price of Methyl Hydroxyethyl Cellulose An Overview

Market demand is also a critical determinant. The construction industry, for example, is a major consumer of MHEC, particularly in the production of cement, mortars, and adhesives. As global construction activities surge, spurred by urbanization and infrastructure development, the demand for MHEC is expected to rise. Increased demand can drive up prices, especially if supply cannot keep pace.

methyl hydroxyethyl cellulose price

Geopolitical factors and trade policies may further affect MHEC prices. Tariffs on imported raw materials or finished products can impact production costs, leading to higher prices for consumers. Additionally, global economic conditions, such as recession or inflation, can indirectly influence purchasing power and, subsequently, demand for MHEC, thus affecting its market price.

Furthermore, technological advancements in the production and application of MHEC can lead to fluctuations in pricing. Innovations that improve yield or reduce waste in the manufacturing process can enable producers to offer competitive prices. Conversely, any disruption in technology or increased regulation concerning production processes—particularly those related to environmental concerns—may lead to increased costs.

When examining the price of MHEC, it is also vital to consider the quality and grade of the product. Higher-purity MHEC, which provides superior performance in demanding applications, often commands a higher price. End-users must balance their need for quality against cost considerations, making it essential to understand the specific requirements of their applications.

In conclusion, the price of Methyl Hydroxyethyl Cellulose is shaped by a confluence of factors, including raw material costs, production complexities, market demand, and technological developments. As industries continue to innovate and evolve, understanding these dynamics will be imperative for stakeholders to navigate the MHEC market effectively. Those involved in the production or application of MHEC must stay informed about market trends, supply chain fluctuations, and advancements in technology to make strategic decisions that align with their financial and operational goals.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025