Dec . 18, 2024 21:04 Back to list

hydroxypropyl methyl cellulose manufacturers

The Role of Hydroxypropyl Methyl Cellulose (HPMC) and Its Manufacturers

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile, non-ionic cellulose ether that has become increasingly important in various industries, ranging from pharmaceuticals and food to construction and personal care. As a manufacturer of HPMC, one is not only contributing to the production of a highly sought-after product but also helping to innovate and enhance numerous applications that rely on its unique properties.

What is HPMC?

HPMC is derived from natural cellulose and is modified through a chemical process to enhance its properties. It is particularly known for its thickening, binding, and emulsifying capabilities. Its solubility in both cold and hot water makes it an excellent choice for applications that require controlled viscosity and stability. In the pharmaceutical industry, HPMC is often used as a thickening agent in gels and as a coating in tablets, providing a controlled-release mechanism that improves absorption. In the construction industry, HPMC is widely used as an additive in mortars and plasters, enhancing their workability and performance.

Key Properties of HPMC

1. Thickening Agent HPMC can increase the viscosity of aqueous solutions, making it a meticulous choice for formulating products ranging from lotions to food sauces. 2. Film-forming Ability When applied, HPMC creates a flexible and transparent film, which is critical for many pharmaceutical applications, including controlled drug release.

3. Emulsification The ability to stabilize oil-in-water emulsions is another critical property of HPMC, making it invaluable in cosmetic formulations and food products.

4. Biocompatibility As a cellulose derivative, HPMC is generally recognized as safe for consumption, making it an ideal additive in food and pharmaceutical products.

Manufacturing Processes

hydroxypropyl methyl cellulose manufacturers

The process of manufacturing HPMC involves several key steps, beginning with the extraction of cellulose from various plant sources. This cellulose is then etherified with propylene oxide and methyl chloride to produce HPMC. The production process must be well-controlled to meet the highest standards of purity and performance.

Quality control is paramount in HPMC manufacturing, as the consistency of the end product can significantly impact its applications. It is common for manufacturers to employ rigorous testing protocols, ensuring that the HPMC produced meets both national and international standards for quality and safety.

Market Demand and Trends

The demand for HPMC is on the rise, driven by the expansion of the food and pharmaceutical sectors, as well as increased construction activities globally. Manufacturers of HPMC are continually innovating to create products that meet the evolving needs of these industries. The trend toward sustainable development is also influencing HPMC manufacturing, with many companies exploring eco-friendly sourcing of raw materials and environmentally friendly production methods.

Moreover, the rise of bio-based products has stimulated interest in HPMC solutions that are derived from sustainable sources. This shift not only addresses environmental concerns but also caters to a market that is increasingly focused on sustainability.

Challenges Faced by Manufacturers

While the demand for HPMC continues to grow, manufacturers face several challenges, including maintaining the high quality of raw materials and ensuring compliance with stringent regulations. Additionally, the competitive landscape is becoming more challenging with the entry of new players into the market. Manufacturers must also invest in research and development to stay ahead of trends and meet customer expectations.

Conclusion

Hydroxypropyl Methyl Cellulose (HPMC) manufacturers play a crucial role in a multitude of industries by providing a product with unique and valuable properties. As demand continues to grow, manufacturers must focus on quality, innovation, and sustainability to remain competitive. The future looks promising for HPMC, as its applications expand and new formulations are developed, paving the way for exciting advancements in various fields. As industry demands evolve, HPMC manufacturers will be at the forefront, pushing the boundaries of what this versatile compound can achieve.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

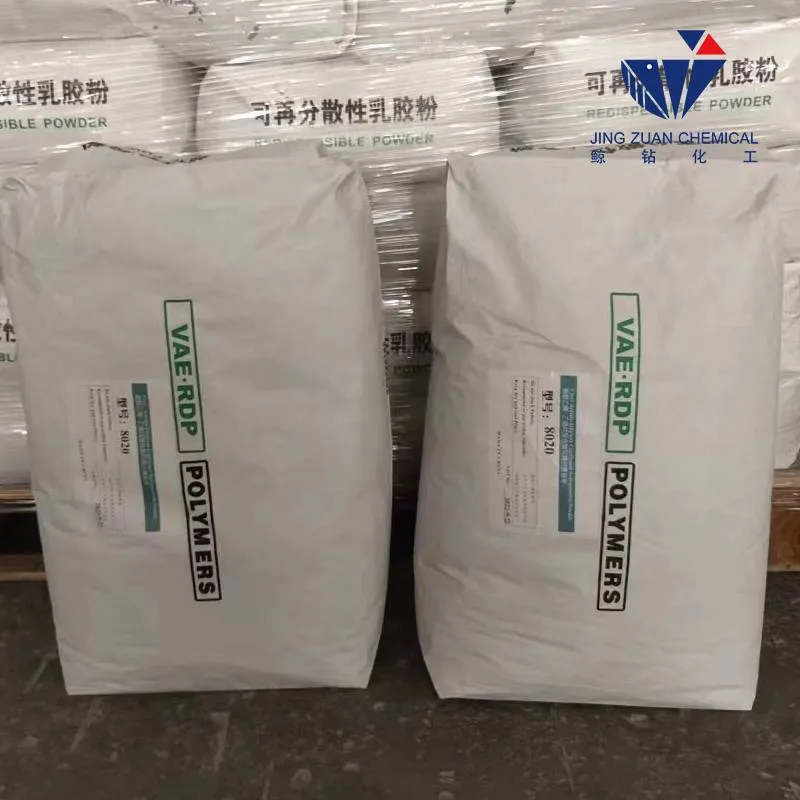

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025