Nov . 27, 2024 08:03 Back to list

Exploring Applications and Benefits of Hydroxypropyl Methyl Cellulose in Various Industries

Understanding Hydroxypropyl Methyl Cellulose (HPMC) Uses, Properties, and Applications

Hydroxypropyl methyl cellulose (HPMC), known by its CAS number 9004-65-3, is a semi-synthetic polymer derived from cellulose. It is a versatile compound widely used across various industries due to its exceptional properties. From construction to pharmaceuticals, HPMC finds numerous applications, enhancing product performance and efficiency.

Properties of HPMC

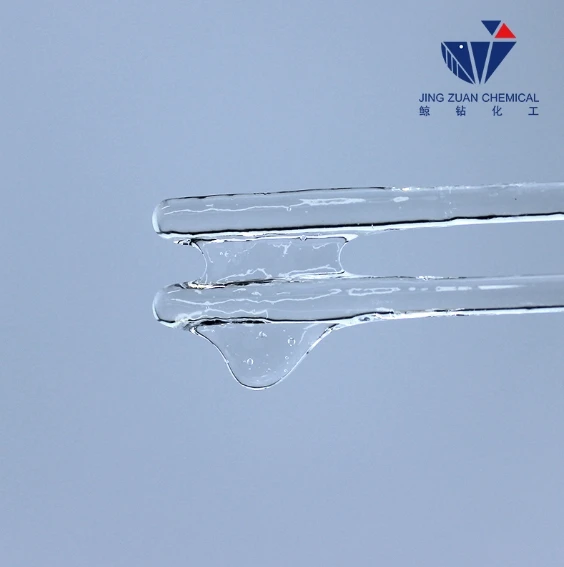

HPMC is characterized by its ability to form gels, emulsions, and films, making it a valuable additive. The compound is soluble in cold water, unlike traditional cellulose derivatives, and has a range of viscosity characteristics that can be tailored to meet specific needs. It is non-toxic and does not possess any intrinsic taste or odor, which makes it suitable for use in food products and pharmaceuticals.

This polymer is unique due to its ability to create a thickening or stabilizing effect in aqueous solutions. The degree of substitution of hydroxypropyl and methyl groups determines the solubility and viscosity of the HPMC, allowing manufacturers to customize the product for specific applications. Whether a low or high viscosity is required, HPMC offers flexibility tailored to particular industrial demands.

Applications of HPMC

1. Pharmaceutical Industry In pharmaceuticals, HPMC is predominantly used as a binder, coating agent, and thickening agent in formulations. Its ability to control release rates in controlled-release tablets highlights its significance. HPMC creates a hydrogel layer around the tablet, which regulates the dissolution and absorption of the drug, ensuring that it is released slowly into the body. This facilitates improved therapeutic efficacy while reducing side effects.

hydroxypropyl methyl cellulose cas number

2. Food Industry HPMC is utilized as a food additive, enhancing the texture, appearance, and stability of various food products. It serves as a thickening agent in sauces, dressings, and soups, improving the mouthfeel and consistency. Additionally, HPMC is employed in gluten-free formulations as an excellent substitute for gluten, providing structural integrity and elasticity to products like bread and pasta.

3. Construction and Building Materials The construction industry benefits significantly from HPMC's properties. It is a key additive in cement-based products, such as mortars and tile adhesives. HPMC improves workability, water retention, and adhesion, ensuring that these materials can be applied smoothly and bond effectively to surfaces without excessive sagging or cracking.

4. Cosmetics and Personal Care In the cosmetics and personal care industry, HPMC functions as a thickener, stabilizer, and emulsifier. It is commonly found in lotions, creams, and gels, enhancing texture and preventing the separation of ingredients. Its ability to form films is also desirable in many cosmetic formulations, providing a smoother application and improved wearer comfort.

5. Agricultural Applications HPMC is used in agriculture as a soil conditioner and as part of seed coating formulations. It improves soil structure and moisture retention, leading to enhanced crop yields. Moreover, when used in herbicides and pesticides, HPMC helps in suspending active ingredients, ensuring even distribution and improved efficacy.

Conclusion

In conclusion, hydroxypropyl methyl cellulose (HPMC) is a remarkable polymer with a wide array of applications across industries. Its unique properties, including solubility in cold water, film-forming capabilities, and thickening characteristics, make it an essential ingredient in pharmaceuticals, food, construction, cosmetics, and agriculture. The adaptability of HPMC allows manufacturers to customize its form and properties to meet the specific requirements of each application, ensuring consistency and reliability in product performance.

With ongoing research and development, the potential applications of HPMC are likely to expand, paving the way for innovative uses and enhanced formulations. As industries continue to seek effective solutions for product formulation and stability, HPMC will remain a key player, contributing to advances in technology and materials science.

-

HPMC for Tile Adhesive: Superior Bonding & Workability

NewsAug.30,2025

-

Premium Cellulose Ether: Effective Liquid Thickener Solutions

NewsAug.29,2025

-

HPMC for Tile Adhesive: Enhanced Bonding & Workability

NewsAug.28,2025

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025

-

trusted-hec-supplier

NewsAug.22,2025