Oct . 06, 2024 05:23 Back to list

hydroxypropyl methyl cellulose cas no

Hydroxypropyl Methylcellulose A Versatile Polymer with Diverse Applications

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic, non-ionic polymer derived from cellulose, which is one of the most abundant organic polymers on Earth. The compound is widely recognized for its unique chemical properties and its expansive applications across various industries, including pharmaceuticals, construction, food, and cosmetics. This article explores the characteristics, production methods, and applications of HPMC, highlighting its significance in contemporary manufacturing and formulations.

Chemical Structure and Properties

HPMC is produced by the etherification of cellulose with propylene oxide and methyl chloride. This chemical process introduces hydroxypropyl and methyl groups into the cellulose structure, leading to a modified polymer with improved solubility, thermal stability, and film-forming capabilities. The degree of substitution (DS) influences its properties, with higher values indicating more modifications and enhanced solubility in water.

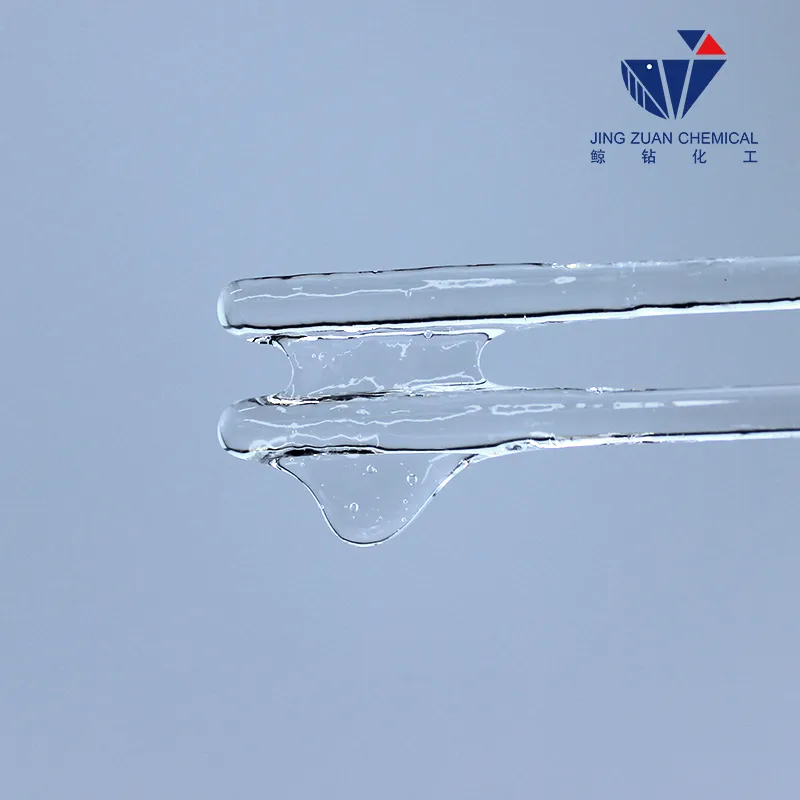

One of the most attractive features of HPMC is its ability to dissolve in cold water, forming a clear, viscous solution without the need for heating. This characteristic makes HPMC an excellent thickening agent, stabilizer, and emulsifier across various applications. Additionally, its low toxicity and biocompatibility make it suitable for use in pharmaceutical formulations and food products.

Applications in Pharmaceuticals

In the pharmaceutical industry, HPMC is extensively used as an excipient—a substance that aids in the processing or function of a drug formulation without providing therapeutic effects. It serves multiple roles, including

1. Binders HPMC is used in tablet formulations to enhance the binding of powder particles, improving the mechanical strength of tablets. 2. Thickening Agents It is often added to liquid formulations to achieve desired viscosities in suspensions and solutions, ensuring uniformity and stability.

hydroxypropyl methyl cellulose cas no

4. Controlled Release Due to its hydrophilic nature, HPMC is a popular choice for developing controlled-release formulations, where the drug is released over an extended period, enhancing therapeutic effectiveness.

Use in the Food Industry

HPMC is also widely used in the food industry as a food additive. As an emulsifier and thickening agent, HPMC helps stabilize food products, improve texture, and increase shelf life. It is particularly beneficial in gluten-free formulations, where it provides the necessary viscosity and mouthfeel that gluten typically offers. HPMC is found in various food products, including sauces, dressings, and baked goods, contributing both functionality and sensory appeal.

Applications in Construction

In the construction sector, HPMC is used as a crucial additive in cement-based products. It enhances water retention, workability, and adhesion of mortars and cement mixtures. This results in improved application and longevity of construction materials. For example, HPMC helps prevent cracking and shrinkage in cement during the drying process, thus enhancing the durability of structures.

Cosmetics and Personal Care

HPMC’s versatility extends to the cosmetics and personal care industry, where it is utilized as a thickener, emulsifier, and stabilizer in various formulations. It ensures a smooth texture in creams, lotions, and gels while providing a pleasant sensory experience. Its compatibility with a wide range of ingredients makes HPMC an ideal choice for formulating products aimed at moisturizing, cleansing, and protecting the skin.

Conclusion

Hydroxypropyl Methylcellulose is an indispensable polymer with a wealth of applications across multiple industries. Its unique properties—such as excellent solubility, non-toxicity, and versatility—make it a preferred choice for formulators seeking effective excipients and additives. As industries continue to innovate and demand new formulations, the role of HPMC is expected to expand, further emphasizing its importance in modern manufacturing and product development. Whether in pharmaceuticals, food, construction, or cosmetics, HPMC remains a key player in enhancing product performance and consumer satisfaction.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025