Dec . 07, 2024 13:37 Back to list

Understanding the Viscosity Characteristics of Hydroxyethyl Cellulose for Various Applications

Understanding Hydroxyethyl Cellulose Viscosity Properties, Applications, and Implications

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from natural cellulose, widely used in various industries due to its unique rheological properties. One of the key characteristics that define its usability is viscosity. In this article, we will explore the significance of HEC viscosity, its influencing factors, applications, and the implications of viscosity in practical scenarios.

What is Hydroxyethyl Cellulose?

Hydroxyethyl cellulose is produced through the etherification of cellulose, where ethylene oxide reacts with hydroxyl groups on the cellulose chain. This modification not only enhances its solubility in water but also improves the polymer's film-forming and thickening capabilities. As a result, HEC is utilized in numerous formulations across various sectors, including pharmaceuticals, cosmetics, food, and construction.

Understanding Viscosity

Viscosity is a measure of a fluid's resistance to flow. In the context of HEC, viscosity plays a critical role in determining how a product behaves under different conditions. It is typically measured in centipoise (cP) and can vary greatly depending on several factors, including the concentration of the HEC solution, the temperature, and the shear rate applied during measurement.

Factors Affecting HEC Viscosity

1. Concentration The concentration of HEC in solution is one of the primary determinants of viscosity. Generally, as the concentration increases, the viscosity of the solution also rises. This relationship is essential for formulating products that require specific flow characteristics.

2. Temperature Viscosity is also temperature-dependent. Higher temperatures usually result in decreased viscosity due to increased molecular movement, making the solution more fluid. Conversely, cooling the solution increases viscosity as the molecular interaction becomes stronger.

3. Shear Rate The application of shear forces can alter the viscosity of HEC solutions. At low shear rates, HEC exhibits a higher viscosity due to the entanglement of polymer chains. However, under high shear conditions, the viscosity decreases as the chains are aligned and disentangled, enabling easier flow. This property is particularly crucial in industries like paints and coatings, where the application process involves varying shear conditions.

hydroxyethyl cellulose viscosity

4. Molecular Weight The molecular weight of HEC also significantly influences its viscosity. Higher molecular weight HEC results in a more viscous solution owing to greater chain entanglements. This aspect must be considered when selecting HEC grades for specific applications.

Applications of Hydroxyethyl Cellulose Based on Viscosity

Given its versatile viscosity characteristics, HEC is used in a wide variety of formulations

- Pharmaceuticals In drug formulations, HEC serves as a thickening agent, stabilizer, and controlled-release agent. Its viscosity properties are crucial for ensuring the effective delivery of active pharmaceutical ingredients.

- Cosmetics In the cosmetic industry, HEC is commonly found in lotions, creams, and gels. Its ability to create a pleasant texture while maintaining stability under varying conditions is highly valued.

- Food Industry HEC is often employed as a thickening and stabilizing agent in food applications. Its viscosity can impact mouthfeel and product consistency, making it an essential ingredient in sauces and dressings.

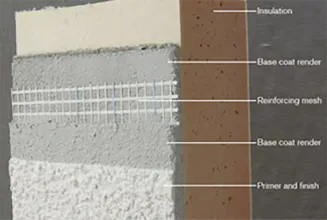

- Construction In the construction industry, HEC is used in dry mixes such as cement and plaster to improve workability and water retention. The viscosity of HEC influences the application and performance of these materials.

Conclusion

Hydroxyethyl cellulose viscosity plays a pivotal role across multiple industries, influencing product formulations and performance. By understanding the factors that affect HEC viscosity—such as concentration, temperature, shear rate, and molecular weight—formulators can optimize products for specific applications. As industries continue to innovate, the demand for tailored HEC solutions will likely increase, underscoring the importance of viscosity as a critical property. Thus, the study of hydroxyethyl cellulose and its viscosity characteristics remains a fascinating and essential part of material science and industrial applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025