Oct . 19, 2024 01:24 Back to list

hydroxyethyl cellulose manufacturing process

Hydroxyethyl Cellulose Manufacturing Process

Hydroxyethyl cellulose (HEC) is a water-soluble polymer derived from cellulose, widely used in various industries, including pharmaceuticals, cosmetics, and food. Its unique properties, such as thickening, binding, and film-forming capabilities, make it an essential ingredient in numerous formulations. The manufacturing process of hydroxyethyl cellulose involves several key steps designed to ensure high purity and performance.

The process begins with the selection of high-quality cellulose sources, typically derived from wood pulp or cotton linters. The cellulose is first treated with an alkaline solution to create alkali cellulose, which enhances its reactivity. This step is crucial as it prepares the cellulose for the subsequent etherification process, where the hydroxyethyl groups will be introduced.

After the formation of alkali cellulose, the next stage involves etherification. In this step, ethylene oxide is used as the etherifying agent. Ethylene oxide reacts with the hydroxyl groups of cellulose to form hydroxyethyl groups, resulting in hydroxyethyl cellulose. The reaction takes place under controlled conditions of temperature and pressure, often in the presence of a catalyst to enhance the efficiency of the reaction. The degree of substitution, which indicates how many hydroxyethyl groups are added to the cellulose backbone, can be controlled by adjusting the reaction conditions, thereby customizing the properties of the final product.

hydroxyethyl cellulose manufacturing process

Once the etherification reaction is complete, the product is neutralized to remove any residual alkali and unreacted ethylene oxide. This neutralization is typically achieved by washing the product with water or an acid solution. The resulting hydroxyethyl cellulose is then precipitated from the reaction mixture, often using alcohol or another solvent to achieve this separation.

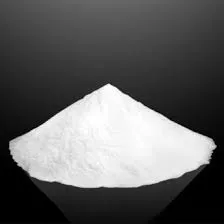

Following precipitation, the hydroxyethyl cellulose undergoes purification to remove any impurities and unreacted materials. This purification process may include filtration, washing, and drying steps, which are crucial for obtaining high-purity HEC. After drying, the product is milled into a fine powder, allowing for easy handling and incorporation into various formulations.

The final product is then packaged and stored under conditions that prevent moisture absorption, which can affect its performance. Quality control measures, including viscosity testing and biological assessments, are implemented to ensure that the hydroxyethyl cellulose meets industry standards and customer specifications.

In summary, the manufacturing process of hydroxyethyl cellulose involves converting cellulose into a hydroxyethyl derivative through a series of carefully controlled chemical reactions. The result is a versatile polymer that plays a critical role in enhancing the performance of products across multiple industries, showcasing the importance of precision in chemical manufacturing processes.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025