Dec . 17, 2024 09:34 Back to list

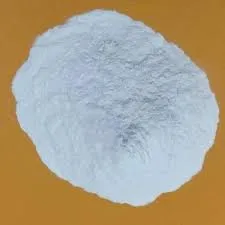

hydroxyethyl cellulose manufacturers

Exploring Hydroxyethyl Cellulose Manufacturers The Key to Quality and Innovation

Hydroxyethyl cellulose (HEC) is a water-soluble cellulose ether that has gained immense popularity across various industries, particularly in construction, personal care, pharmaceuticals, and food processing. Its versatility stems from its thickening, binding, and film-forming properties, making it an essential ingredient in numerous applications. As demand continues to rise, the role of hydroxyethyl cellulose manufacturers has become increasingly significant in delivering high-quality products that meet industry standards.

The Importance of Hydroxyethyl Cellulose

HEC is valued for its ability to modify the viscosity and texture of a wide array of formulations during production. For example, in the construction industry, HEC acts as a thickener in cement-based products such as adhesives, mortars, and grouts. By improving the workability and water retention of these products, manufacturers can ensure that their formulations perform effectively under various conditions, ultimately enhancing durability and user satisfaction.

In the cosmetics and personal care sector, hydroxyethyl cellulose serves to stabilize emulsions, improve the texture of creams and lotions, and enhance the overall sensory experience for consumers. Similarly, in pharmaceuticals, HEC is used as an excipient to control the release of active ingredients, ensuring that medications have the desired bioavailability and efficacy.

The Growing Market for Hydroxyethyl Cellulose

The global market for hydroxyethyl cellulose is projected to experience significant growth, driven by the increasing demand for sustainable and eco-friendly products. As industries shift towards environmentally responsible formulations, manufacturers of HEC are adapting to meet these new expectations.

One major trend is the rising interest in bio-based ingredients

. HEC is derived from natural cellulose, making it a preferred choice for companies looking to minimize their carbon footprint. Manufacturers are not only focusing on sustainable sourcing but are also investing in innovative production processes that reduce waste and energy consumption.Key Considerations for Choosing HEC Manufacturers

When selecting a hydroxyethyl cellulose manufacturer, several key factors must be taken into account to ensure product quality and reliability.

hydroxyethyl cellulose manufacturers

1. Quality Assurance It is critical to work with manufacturers that adhere to stringent quality control measures. This can include certifications such as ISO 9001, which demonstrates a commitment to maintaining high standards throughout the production process.

2. Research and Development Innovative manufacturers actively invest in R&D to develop new grades of HEC that cater to specific application requirements. This capacity for innovation directly impacts the performance of the products they offer.

3. Technical Support A valuable partner in any industry is a manufacturer that provides comprehensive technical support. This includes assistance with formulation and troubleshooting, helping clients optimize the performance of HEC in their products.

4. Sustainability Practices As more companies aim for sustainable practices, aligning with HEC manufacturers that prioritize eco-friendly production methods can enhance brand reputation and consumer loyalty.

5. Geographical Location The location of the manufacturer can influence shipping costs and delivery times. Choosing a locally-based supplier can facilitate faster turnaround times, ensuring that production schedules are maintained.

Prominent Hydroxyethyl Cellulose Manufacturers

Several well-established companies are recognized leaders in the hydroxyethyl cellulose market. These manufacturers offer a range of product grades and formulations designed to meet the specific needs of different industries. Companies such as Ashland, Dow, and Nouryon have gained prominence for their commitment to quality, innovation, and customer service.

Emerging manufacturers are also entering the market, often bringing fresh ideas and sustainable practices to their operations. Collaborating with these new players can provide companies with access to novel products that set them apart in a competitive landscape.

Conclusion

Hydroxyethyl cellulose manufacturers play a pivotal role in the supply chain of various industries, providing essential materials that enhance product performance. As the market continues to evolve, these manufacturers are embracing innovation and sustainability to meet the ever-changing needs of their clients. By carefully selecting a reliable HEC supplier, businesses can not only improve their formulations but also contribute to a more sustainable future. Whether in construction, personal care, or pharmaceuticals, the right HEC manufacturer can be a catalyst for quality and innovation.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025