Dec . 25, 2024 13:06 Back to list

Hydroxyethyl Cellulose Production and Applications in Various Industries

Understanding Hydroxyethyl Cellulose The Role of Manufacturers in the Industry

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer that has garnered significant attention across various industries, including pharmaceuticals, cosmetics, food, and construction. As a derivative of cellulose, HEC possesses unique properties that make it an indispensable component in numerous applications. This article explores the significance of hydroxyethyl cellulose manufacturers and their contributions to various sectors.

What is Hydroxyethyl Cellulose?

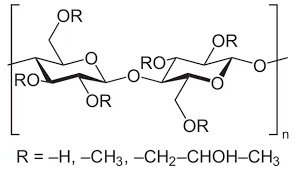

Hydroxyethyl cellulose is synthesized from natural cellulose through a process of etherification. The introduction of hydroxyethyl groups to the cellulose backbone enhances its solubility in water and improves its viscoelastic properties. As a result, HEC is frequently used as a thickening and stabilizing agent, providing desirable rheological characteristics to formulations. Its versatility, safety, and compatibility with other materials make it ideal for numerous applications.

Applications of Hydroxyethyl Cellulose

1. Pharmaceuticals HEC is widely used in drug formulations, particularly in topical creams, gels, and ointments. It acts as a thickener and film-forming agent, enhancing the product's texture and stability. Additionally, HEC can help control the release of active ingredients, making it an essential component in controlled-release formulations.

2. Cosmetics The cosmetic industry has embraced HEC for its ability to provide a smooth consistency and improve the spreadability of lotions, shampoos, and conditioners. It helps retain moisture and offers a pleasant feel to skin and hair care products. Manufacturers leverage HEC to create products that cater to diverse consumer preferences, from lightweight gels to rich creams.

3. Food Industry Hydroxyethyl cellulose serves as a food additive, improving texture and mouthfeel in various products. It is commonly found in sauces, dressings, and dairy products where it acts as a stabilizer and emulsifier. HEC is also embraced for its ability to provide a gluten-like texture in gluten-free formulations, catering to the growing demand for gluten-free products.

4. Construction In the construction industry, HEC is utilized in tile adhesives, paints, and coatings. It enhances workability, extends open time, and improves adhesion on surfaces. The inclusion of HEC in construction materials ensures optimal performance, meeting the demands of modern construction practices.

hydroxyethyl cellulose manufacturer

Role of Manufacturers

Hydroxyethyl cellulose manufacturers play a crucial role in ensuring the quality, availability, and innovation of HEC products. Here are several key responsibilities they undertake

1. Quality Control Manufacturers are responsible for producing HEC that meets stringent quality standards. This involves rigorous testing of raw materials and final products to ensure consistency in performance and compliance with regulatory requirements.

2. Innovation Research and development are integral to the success of HEC manufacturers. By exploring new production methods and applications, manufacturers can develop specialized grades of HEC that meet specific market needs. Innovations may include tailoring the viscosity, solubility, and other properties to suit different applications.

3. Sustainability As environmental concerns rise, manufacturers are increasingly focusing on sustainable practices. This includes sourcing raw materials responsibly and minimizing waste during production. Eco-friendly approaches resonate with consumers and businesses alike, driving demand for sustainably produced HEC.

4. Customer Support Effective communication and support are vital aspects of a manufacturer’s role. They provide technical assistance, product knowledge, and formulation advice to customers, ensuring that clients can optimize the use of HEC in their formulations. Building strong relationships with clients enhances customer satisfaction and fosters loyalty.

5. Global Expansion With globalization, manufacturers are seeking to expand their reach into emerging markets. By establishing distribution networks and partnerships in various regions, HEC manufacturers can tap into new opportunities, bringing their products to a broader audience.

Conclusion

The significance of hydroxyethyl cellulose manufacturers cannot be overstated. Their contributions to maintaining quality, driving innovation, and ensuring sustainability are essential for the continued growth and success of industries relying on HEC. As diverse applications continue to evolve, the adaptability and performance of hydroxyethyl cellulose will undoubtedly position it as a crucial ingredient for the future. With a focus on quality and sustainability, manufacturers will continue to play a pivotal role in shaping the landscape of this valuable polymer, ultimately benefiting consumers and industries alike.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025