Nov . 27, 2024 00:35 Back to list

Preparation Methods for HPMC Solutions in Pharmaceutical Applications

HPMC Solution Preparation A Comprehensive Guide

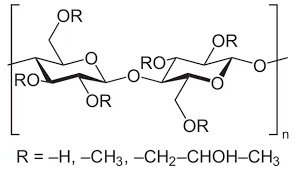

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used in various industrial applications, including pharmaceuticals, food, cosmetics, and construction. It acts as a thickening agent, emulsifier, and stabilizer, making it essential in formulating a variety of products. Preparing an HPMC solution requires careful attention to detail to ensure the desired viscosity and consistency. This article outlines the step-by-step process of preparing an HPMC solution effectively.

Understanding HPMC

HPMC is a cellulose derivative that is non-toxic, biodegradable, and forms a clear, gel-like solution when mixed with water. The degree of substitution and molecular weight of HPMC can vary, impacting its solubility and thickening properties. Understanding these characteristics is crucial when selecting the appropriate HPMC grade for your specific application.

Materials Required

To prepare an HPMC solution, you will need

1. Hydroxypropyl Methylcellulose (HPMC) Powder Choose the grade based on the desired viscosity and application. 2. Distilled Water To ensure purity and prevent contamination. 3. Mixing Vessel Preferably a container made of stainless steel or glass to avoid chemical reactions. 4. Stirring Device A mechanical stirrer or a high-shear mixer will ensure uniform dispersion of HPMC in water. 5. Heat Source (if necessary) Depending on the grade of HPMC, slight heating may be required for solubility.

Step-by-Step Preparation

1. Determine Concentration Decide the concentration of HPMC needed for your application. Typical concentrations range from 0.5% to 2% w/v, but this can vary based on the required viscosity.

2. Measure HPMC and Water Accurately weigh the desired amount of HPMC powder and measure the corresponding amount of distilled water. It is important to maintain the correct ratio for optimal results.

hpmc solution preparation

3. Pre-Mixing To avoid clumping, add the HPMC powder slowly to the water while stirring continuously. This step is crucial as it helps to disperse the powder and prevents agglomeration.

4. Hydration Allow the mixture to sit undisturbed for about 15-30 minutes. This step allows the HPMC particles to absorb water and swell, leading to better solubility.

5. Stirring After the hydration period, use a mechanical stirrer or a high-shear mixer to mix the solution thoroughly. Aim for a consistent and homogeneous mixture without lumps. If you notice any clumps, continue mixing until they are fully dispersed.

6. Heating (if necessary) If preparing a solution with high viscosity or using a grade of HPMC that requires heat for full solubility, gently warm the solution to about 60°C. Avoid boiling to prevent degradation of the polymer. Stir continuously during this process.

7. Cooling Once the HPMC is fully dissolved and the solution has reached the desired viscosity, allow it to cool to room temperature.

8. Storage Transfer the prepared HPMC solution into a clean, labeled container. Store the solution in a cool, dry place. Proper storage is essential to maintain the stability and effectiveness of the solution.

Troubleshooting Common Issues

1. Clumping If clumps form during initial mixing, consider increasing the stirring speed or changing the mixing technique. 2. Insufficient Viscosity If the solution is not as viscous as expected, you may need to adjust the concentration of HPMC or ensure complete dissolution. 3. Foaming To minimize foaming, avoid excessive stirring and consider using an anti-foaming agent if necessary.

Conclusion

Preparing an HPMC solution, while straightforward, requires precision and attention to detail to achieve optimal results. By following the outlined steps and understanding the properties of HPMC, you can create a stable and effective solution suitable for various applications. Whether in the pharmaceutical industry or food production, HPMC continues to be a crucial ingredient in enhancing the quality and performance of products across multiple sectors.

-

HPMC for Tile Adhesive: Superior Bonding & Workability

NewsAug.30,2025

-

Premium Cellulose Ether: Effective Liquid Thickener Solutions

NewsAug.29,2025

-

HPMC for Tile Adhesive: Enhanced Bonding & Workability

NewsAug.28,2025

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025

-

trusted-hec-supplier

NewsAug.22,2025