Nov . 21, 2024 17:09 Back to list

hpmc solution preparation

HPMC Solution Preparation A Comprehensive Guide

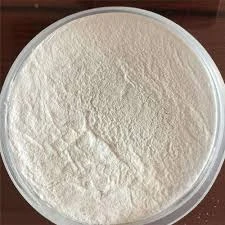

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used in pharmaceutical, cosmetic, and food industries due to its properties as a thickening agent, emulsifier, and film-former. Proper preparation of HPMC solutions is crucial for ensuring the desired viscosity and performance in various applications. This article outlines the key steps and considerations for preparing HPMC solutions.

HPMC Solution Preparation A Comprehensive Guide

Once the HPMC grade is determined, the next step involves measuring the required amount of HPMC powder. The concentration of HPMC in the solution will influence its thickening properties and viscosity. Typical concentrations range from 0.5% to 5%, depending on the intended use. Precision in measurement is vital to achieving consistency in the final product.

hpmc solution preparation

HPMC is not immediately soluble in water; thus, it requires careful dispersion to avoid clumping. To do this, it is recommended to slowly sprinkle the HPMC powder into room-temperature or lukewarm water while continuously stirring. Using a high-shear mixer or a vortex mixer can facilitate better dispersion and prevent agglomeration.

Once the HPMC is fully dispersed, the solution can be heated gently to promote complete dissolution. It is important to avoid boiling the solution, as excessive heat can degrade the polymer. After heating, the solution should be allowed to cool gradually while continuing to stir. This process helps achieve a uniform consistency and enhances the solubility of the polymer.

After the solution has cooled, it is essential to check the pH if the application requires it, as HPMC can be sensitive to pH changes. Adjustments can be made using appropriate buffering agents. Finally, the prepared HPMC solution should be stored in a clean, airtight container to prevent contamination and maintain its stability.

In conclusion, the successful preparation of HPMC solutions involves careful selection of the polymer grade, accurate measurements, effective dispersion, controlled heating, and proper storage. By following these guidelines, manufacturers can ensure high-quality HPMC solutions suitable for a wide range of industrial applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025