Nov . 25, 2024 17:50 Back to list

hpmc manufacturer

The Role of HPMC Manufacturers in the Pharmaceutical Industry

Hydroxypropyl Methylcellulose (HPMC) is a cellulose derivative that has gained significant traction across various industries, particularly in pharmaceuticals. As a crucial excipient, HPMC is utilized in various formulations, including oral tablets, capsules, and topical applications. Understanding the importance of HPMC manufacturers is essential to recognize how they contribute to the pharmaceutical landscape.

The Role of HPMC Manufacturers in the Pharmaceutical Industry

The demand for HPMC has surged in recent years, and this trend is largely driven by the rising need for effective and efficient drug delivery systems. As patients increasingly seek medications that are easier to consume and have fewer side effects, HPMC has emerged as a favored excipient. This shift has prompted pharmaceutical companies to partner with HPMC manufacturers to ensure a consistent supply of high-quality material that meets stringent regulatory standards.

hpmc manufacturer

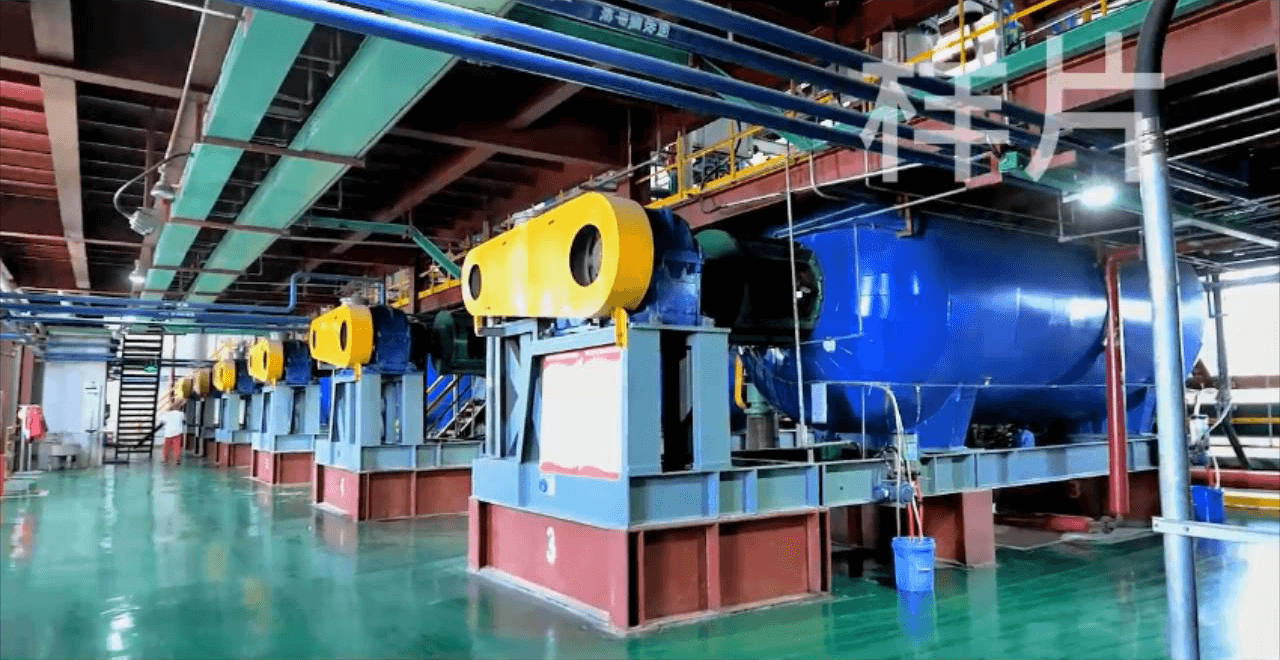

HPMC manufacturers play a pivotal role in the production process. They are responsible for the synthesis of hydroxypropyl methylcellulose through controlled chemical processes that ensure the desired molecular weight and viscosity. The purity of HPMC is paramount, and manufacturers must adhere to Good Manufacturing Practices (GMP) to ensure that the product is free from contaminants and suitable for pharmaceutical use. The rigorous quality control protocols adopted by reputable HPMC manufacturers result in products that pharmaceutical companies can trust.

Moreover, the customization of HPMC is an essential service provided by manufacturers. Different formulations require varying grades of HPMC based on viscosity, molecular weight, and solubility. Manufacturers often collaborate with their pharmaceutical clients to develop tailored solutions that meet specific formulation challenges. This level of cooperation fosters innovation and enables the development of novel drug delivery systems, such as controlled-release tablets and gel formulations.

Another critical aspect to consider is the environmental impact of HPMC production. Many HPMC manufacturers have adopted sustainable practices, such as using renewable raw materials and reducing waste. As the pharmaceutical industry is increasingly prioritizing sustainability, working with HPMC manufacturers that value eco-friendly practices can be beneficial for companies looking to improve their overall environmental footprint.

In conclusion, HPMC manufacturers are instrumental in the pharmaceutical sector, providing essential materials that enhance drug formulation and delivery. With their ability to produce high-quality, customizable HPMC that complies with industry regulations, these manufacturers enable pharmaceutical companies to innovate and meet the evolving needs of patients. As demand for HPMC continues to grow, the collaboration between manufacturers and pharmaceutical firms will be crucial in shaping the future of drug delivery systems, making HPMC an indispensable component in the ever-evolving pharmaceutical landscape.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025