Nov . 04, 2024 17:16 Back to list

HPMC Producers and Their Role in Various Industries and Applications

Understanding HPMC Manufacturers A Key Component in Modern Industry

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used product in various industries, including pharmaceuticals, food, construction, and personal care. As a cellulose ether, HPMC is synthesized from natural cellulose and modified to enhance its properties, leading to diverse applications. The role of HPMC manufacturers is crucial in the supply chain, ensuring that high-quality products meet the specific needs of different industries.

The Role of HPMC Manufacturers

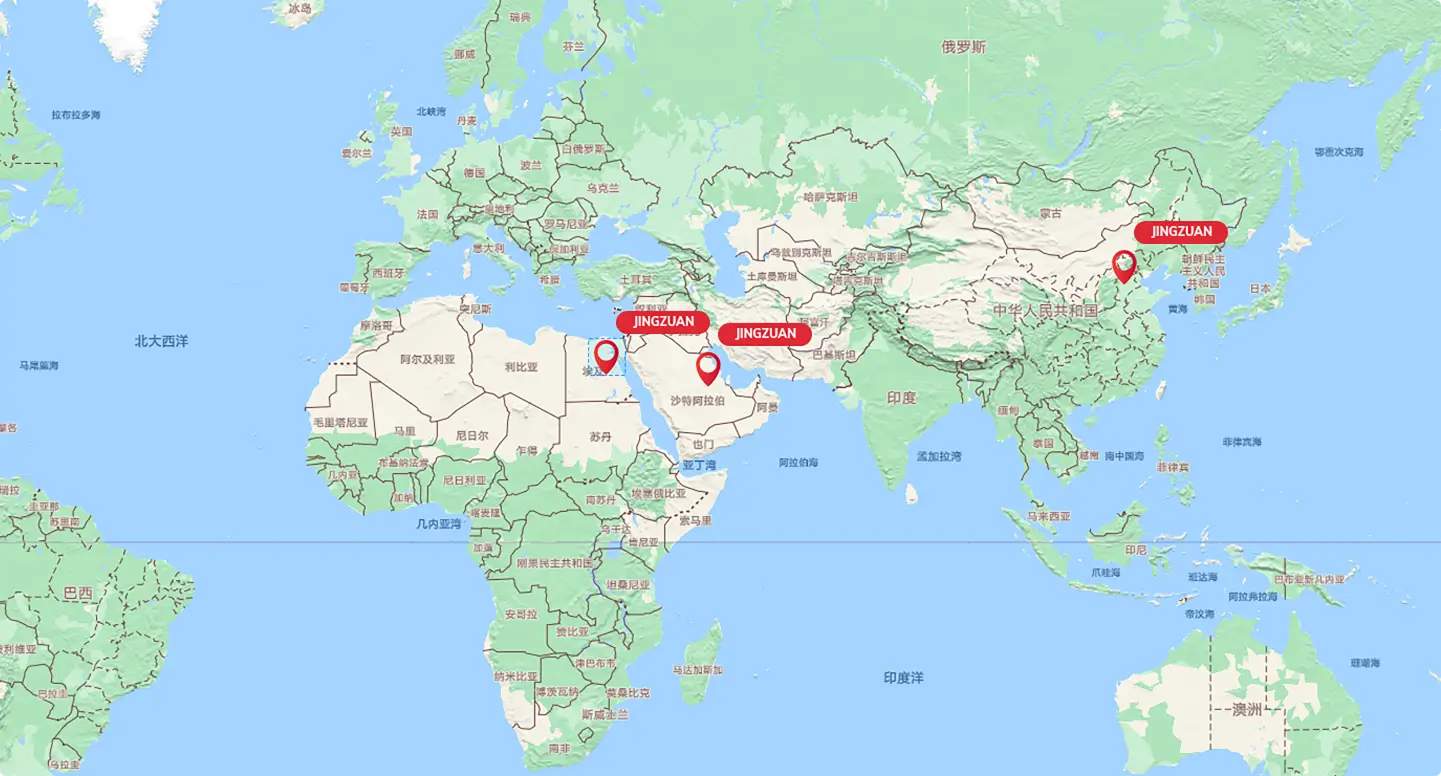

HPMC manufacturers are responsible for producing and supplying this essential component to markets around the globe. They utilize advanced technologies and rigorous quality control processes to ensure that their products meet international standards. The manufacturing process typically involves the alkalization of cellulose, followed by etherification with propylene oxide and methyl chloride. This multi-step process requires precision and expertise, underscoring the importance of skilled labor and modern facilities in the industry.

Quality assurance is paramount in the production of HPMC. Renowned manufacturers conduct extensive testing on their products, adhering to stringent industry regulations. This includes evaluating viscosity, appearance, and moisture content to ensure consistency and reliability. By maintaining high standards, manufacturers not only build trust with their clients but also contribute to the overall safety and efficacy of the end products in which HPMC is used.

Applications of HPMC

The versatility of HPMC makes it suitable for a vast array of applications. In the pharmaceutical industry, it acts as a binder, thickener, and controlled-release agent in tablet formulations. Its ability to form gels and retain moisture makes it an invaluable ingredient in various formulations, enhancing the effectiveness of medicines.

In the construction sector, HPMC serves as a crucial additive in cement-based products like mortar and plaster. By improving workability and water retention, HPMC enhances the performance of these materials, leading to stronger and more durable structures. Additionally, its use in tile adhesives ensures proper adhesion and flexibility, which are vital in preventing damage in varying environmental conditions.

hpmc manufacturer

In the food industry, HPMC is employed as a thickening agent, emulsifier, and stabilizer. Its ability to improve the texture and shelf life of food products makes it a popular choice among food manufacturers. Moreover, HPMC is often highlighted in the production of gluten-free products, where it plays a critical role in replicating the texture of gluten-containing foods.

The personal care industry also benefits from HPMC, as it is incorporated into a variety of cosmetics and toiletries. Its properties allow for improved viscosity and stability in products like lotions, shampoos, and gels. HPMC not only enhances the sensory feel of these products but also extends their shelf life, making it a preferred choice for formulators.

The Future of HPMC Manufacturing

As consumer demands evolve and industries prioritize sustainability, HPMC manufacturers are expected to innovate and adapt. The shift towards eco-friendly practices has prompted manufacturers to explore sustainable sources for cellulose and reduce waste in their production processes. Additionally, advancements in technology may lead to more efficient manufacturing techniques, further lowering costs and enhancing product quality.

Furthermore, as global markets expand, HPMC manufacturers will face the challenge of meeting diverse regional regulations and standards. This requires a commitment to continuous improvement and investment in research and development to tailor products to specific market needs.

Conclusion

In summary, HPMC manufacturers play a vital role in the modern industrial landscape. Their commitment to quality, innovation, and sustainability ensures that HPMC remains a valuable component across various sectors. As industries continue to evolve, the importance of reliable and high-quality HPMC will only grow, making these manufacturers key players in the future of multiple applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025