Nov . 29, 2024 19:55 Back to list

Understanding HPMC Grades and Their Applications in Pharmaceutical Formulations

Understanding HPMC Grades A Comprehensive Overview

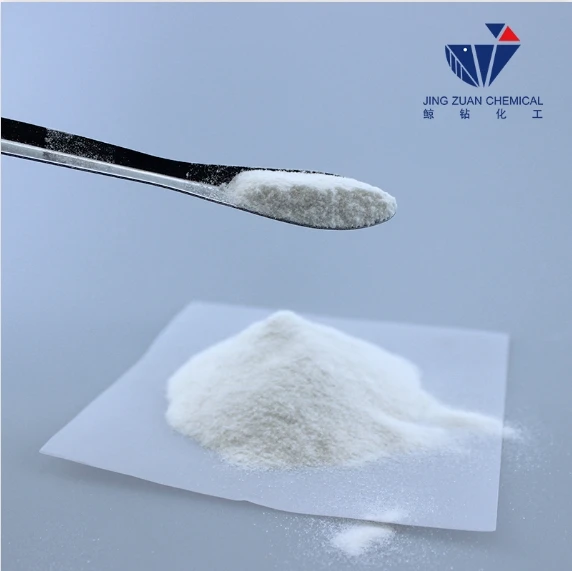

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used in various industries, including pharmaceuticals, food, and construction. Its different grades are tailored for specific applications, making it crucial to understand their characteristics and uses. This article explores the various HPMC grades and their significance.

Understanding HPMC Grades A Comprehensive Overview

One of the most common applications of HPMC is in the pharmaceutical industry. It is used as a binder in tablet formulations, aiding in the cohesion of the ingredients and ensuring uniformity. In this context, HPMC grades such as E, K, and M are frequently utilized, with 'E' grades typically having lower viscosity, making them suitable for quick-dissolving tablets, while 'K' grades, with higher viscosity, are ideal for sustained-release formulations. The selection of the appropriate grade is pivotal in achieving the desired release profiles and therapeutic outcomes.

hpmc grades pdf

In the food industry, HPMC serves as a thickening agent and emulsifier. It helps improve texture and stability in various products, including sauces, dressings, and baked goods. Here, lower-viscosity grades are often preferred to maintain a desirable mouthfeel without affecting the overall product consistency. The food-grade HPMC is high-purity, ensuring that it is safe for consumption, thus adhering to strict regulatory standards.

Construction is another field where HPMC plays a vital role. It is commonly used in tile adhesives, patching compounds, and drywall joint compounds. The ability of HPMC to retain water and improve workability while providing excellent adhesive properties makes it an invaluable component in construction materials. In this sector, higher-viscosity grades are typically used to enhance performance and ensure effective application.

The versatility and adaptability of HPMC grades across various applications underscore its importance in multiple industries. Each grade offers unique properties, making it essential for manufacturers to select the appropriate type based on their specific needs. As ongoing research continues to expand the understanding and capabilities of HPMC, its relevance is expected to grow, further establishing it as a critical ingredient in both existing and emerging applications.

In conclusion, HPMC grades represent a fundamental aspect of material science, with their diverse functionalities significantly impacting product development in pharmaceuticals, food, and construction. Understanding these grades is essential for optimizing formulations and maximizing performance in various industries.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025