Nov . 10, 2024 18:36 Back to list

Exploring HPMC Grades and Their Applications in Pharmaceutical Formulations

Understanding HPMC Grades A Comprehensive Overview

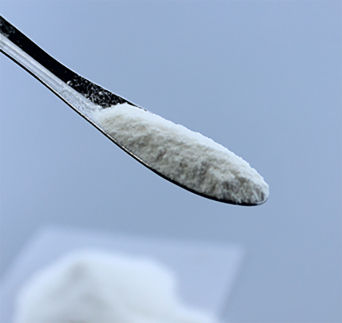

Hydroxypropyl methylcellulose (HPMC) is a versatile polymer widely used in pharmaceutical, food, and construction industries. Its unique properties such as water solubility, gelling ability, and film-forming capacity make it a popular choice for various applications. This article explores the different grades of HPMC, their characteristics, and their specific applications.

What is HPMC?

HPMC is a non-ionic, cellulose-based polymer that is derived from natural cellulose. The hydroxylpropyl and methyl substitutions along the cellulose backbone contribute to its unique functional properties. HPMC is primarily used as a thickening agent, emulsifier, and film-former, serving as an essential ingredient in many formulations.

Classification of HPMC Grades

HPMC comes in various grades, each designed for specific functions based on its viscosity, degree of substitution, and molecular weight. These factors influence its performance in applications such as drug delivery, food thickening, and construction materials. Here are some of the common grades of HPMC

1. Low Viscosity Grades These grades have a lower molecular weight and are typically used in applications requiring quick viscosity build-up and rapid solubility. They are ideal for dry mixes, particularly in the food industry, where they help maintain consistency without significantly increasing the weight or viscosity of the final product.

2. Medium Viscosity Grades These grades provide a balance between thickening and film-forming capabilities. They are widely utilized in pharmaceutical applications, particularly in tablet formulations, where they improve binding and control the release of active ingredients.

3. High Viscosity Grades Designed for more demanding applications, high viscosity grades offer superior thickening and stabilizing properties. These are particularly useful in formulations requiring a stable gel or high viscosity, making them popular in both personal care products and construction adhesives.

Characteristics of HPMC

hpmc grades pdf

Each HPMC grade offers unique characteristics, influencing its applicability

- Solubility HPMC is soluble in cold or hot water, which makes it an excellent choice for applications that require a thermoreversible gel or solution. - Thermal Stability It maintains stability under a wide range of pH and temperature conditions, allowing for its use across various formulations. - Bio-compatibility HPMC is regarded as safe for human consumption, making it a frequently utilized ingredient in the food and pharmaceutical sectors.

Applications of HPMC Grades

1. Pharmaceutical In drug formulations, HPMC grades are crucial for controlling drug release profiles, improving stability, and enhancing patient adherence. Various forms of tablets and capsules incorporate medium to high viscosity grades for optimal performance.

2. Food Industry Low viscosity HPMC grades are used in a variety of food products as thickeners or stabilizers, enhancing texture without altering flavor profiles. It is also used in gluten-free baking to improve the structure and moisture retention of baked goods.

3. Construction High viscosity HPMC grades are incorporated in tile adhesives, plaster, and paints to improve workability and adhesion properties, accommodating the demands of construction applications.

4. Cosmetics and Personal Care HPMC is often included in creams, lotions, and gels to improve texture, provide moisture retention, and offer a pleasing sensory profile.

Conclusion

The versatility and functional properties of HPMC make it a valuable ingredient across various industries. Understanding the different grades of HPMC and their respective applications play a crucial role in selecting the right product for specific needs. As innovation continues in formulation science, HPMC is likely to evolve and adapt, continuing to meet the demands of diverse applications in the future.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025