Sep . 28, 2024 21:21 Back to list

HPMC Varieties and Their Applications in Various Industries and Products

Understanding HPMC Grades and Uses

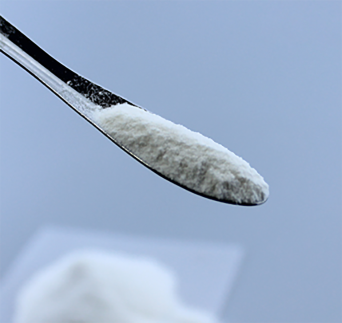

Hydroxypropyl Methylcellulose (HPMC) is a cellulose ether that has gained immense popularity across various industries due to its versatile properties. This compound is synthesized through the modification of cellulose, a naturally occurring polymer, to enhance its functionality in diverse applications. HPMC is widely utilized in pharmaceuticals, food, cosmetics, and construction, primarily for its thickening, emulsifying, and film-forming capabilities. To effectively employ HPMC, it is imperative to understand its different grades and their respective uses.

HPMC Grades

The classification of HPMC is predominantly based on its viscosity, degree of substitution, and the solubility in water. The viscosity of HPMC solutions can range from low to high, affecting the rheological properties that make it suitable for various applications. Common grades include

1. Low Viscosity Grades These grades exhibit rapid dissolution in water, forming low-viscosity solutions. They are typically used as dispersants, aiding in the uniform mixing of powders in various formulations.

2. Medium Viscosity Grades This category strikes a balance between ease of handling and thickening ability. The medium viscosity HPMC is predominantly used in adhesive formulations, paints, and bakery products, where a moderate thickening effect is desired without altering texture.

3. High Viscosity Grades High viscosity HPMC grades form thick, gel-like solutions, making them ideal for applications such as coatings, construction materials, and personal care products. Their ability to provide superior texture, stability, and moisture retention makes them essential in these industries.

4. Specialty Grades Some HPMC grades are tailored for specific applications, such as those with enhanced thermal stability or modified release properties. These specialty grades address unique functional requirements in various high-performance formulations.

hpmc grades and uses

Uses of HPMC

1. Pharmaceuticals In the pharmaceutical sector, HPMC is extensively used as a binder, coating agent, and controlled release agent in tablet manufacturing. Its ability to form a film enhances the stability of active pharmaceutical ingredients while providing controlled drug release properties. Additionally, HPMC is utilized in ophthalmic preparations and as a suspending agent in liquid formulations.

2. Food Industry HPMC is commonly found in food products as a food additive, often labeled as E464. It serves multiple functions, including acting as a thickener, emulsifier, and stabilizer in sauces, dressings, and creams. Its plant-based origins make it a preferred choice for vegetarian and vegan formulations.

3. Cosmetics and Personal Care The cosmetic industry leverages HPMC for its thickening and emulsifying properties. It is incorporated into creams, lotions, and gels to enhance texture and improve product stability. HPMC is also used in hair care products for providing a smooth feel without greasiness.

4. Construction In the construction sector, HPMC acts as a water-retaining agent in cement-based formulations like tile adhesives and plasters. It improves workability, extends drying time, and enhances adhesion properties, making it an essential component in construction materials.

5. Other Applications HPMC's versatility extends to various other applications, including adhesives, paints, and coatings. Its non-toxic nature and ability to modify viscosity make it valuable in industries seeking sustainable and environmentally friendly solutions.

Conclusion

HPMC represents a critical ingredient across numerous industries, driven by its unique properties and adaptability. Understanding the different grades of HPMC and their specific applications enables industries to select the ideal formulation for their needs. As demand for natural and effective alternatives continues to grow, HPMC is poised to remain at the forefront of innovation in various sectors, from pharmaceuticals to construction, emphasizing its role as a multifaceted and indispensable material in modern applications. With research and advancements in production techniques, the scope of HPMC is likely to expand, further enhancing its utility across different fields.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025