Nov . 07, 2024 09:12 Back to list

Understanding HPMC Grades and Their Applications in Various Industries

Understanding HPMC Grades Properties and Applications

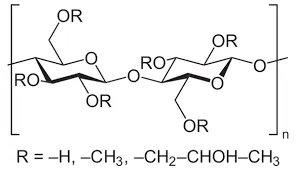

Hydroxypropyl Methylcellulose (HPMC) is a synthetic polymer derived from cellulose. It is widely used as a thickening agent, emulsifier, and stabilizer across various industries, including pharmaceuticals, food, and cosmetics. The different grades of HPMC are categorized based on their chemical composition, viscosity, and physical properties, allowing users to select the appropriate grade for their specific application.

What are HPMC Grades?

HPMC is available in several grades, differentiated primarily by their viscosity, degree of substitution, and the molecular weight of the polymer. The viscosity of HPMC solutions can range from low to high, with low viscosity grades being used for applications requiring less thickening, and high viscosity grades providing enhanced thickening and gel-forming properties.

1. Low Viscosity Grades These grades are typically used in applications that require fast dissolution and a smoother texture. Examples include low-calorie food products or certain pharmaceutical formulations that demand rapid release of active ingredients.

2. Medium Viscosity Grades Medium viscosity HPMC grades strike a balance between thickness and fluidity. They are commonly found in products such as cosmetics, where a cream or gel-like consistency is desirable without being overly viscous.

3. High Viscosity Grades High viscosity HPMC grades are characterized by their ability to form thick gels and provide excellent stability. These grades are often employed in building materials and pharmaceuticals, where high viscosity is crucial for product performance.

Key Properties of HPMC

The properties of HPMC that make it indispensable in various applications include

- Hydrophilicity HPMC is soluble in water, making it an excellent choice for applications requiring water retention and moisture regulation. Its hydrophilic nature allows for improved texture in food products and smoothness in cosmetic formulations.

- Thermal Stability HPMC exhibits good thermal stability, allowing it to maintain its properties even under high-temperature conditions. This characteristic is particularly important in some food processing and pharmaceutical applications.

hpmc grades

- Controlled Release In pharmaceutical formulations, HPMC can be used to create controlled-release drug delivery systems. Its gel-forming ability helps in sustaining the release of active ingredients over extended periods, leading to improved therapeutic outcomes.

- Biocompatibility As a cellulose derivative, HPMC is considered safe for various applications, including those involving food and pharmaceuticals. Its biocompatibility is crucial for consumer safety and regulatory compliance.

Applications of HPMC

HPMC is versatile and finds applications across multiple sectors

1. Pharmaceuticals In the pharmaceutical industry, HPMC is used as a binder in tablet formulations, as well as a thickener in suspensions and emulsions. Its ability to control the release of drugs is particularly valuable in extended-release formulations.

2. Food Industry HPMC is commonly employed as a food additive for thickening and stabilization in products like sauces, dressings, and ice cream. It enhances texture and mouthfeel while also improving shelf life.

3. Cosmetics and Personal Care In the cosmetic industry, HPMC is found in lotions, creams, and gels. It acts as a thickening and emulsifying agent, improving the product’s overall aesthetic properties.

4. Construction In construction materials, HPMC is used in dry-mixed mortars and adhesives. Its water-retaining properties help in improving the workability and adhesion of these materials.

Conclusion

The various grades of HPMC offer a myriad of options for industries ranging from pharmaceuticals to food and cosmetics. Understanding the specific properties and applications of different HPMC grades is crucial for manufacturers aiming to achieve optimal product performance. As industries continue to evolve, the demand for specialized HPMC grades is likely to grow, paving the way for innovative formulations and applications. By leveraging the multifunctional characteristics of HPMC, businesses can enhance their product offerings and meet the ever-changing needs of consumers.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025