Nov . 27, 2024 22:13 Back to list

HPMC Applications and Benefits in Wall Putty Formulations for Enhanced Performance

Understanding HPMC for Wall Putty

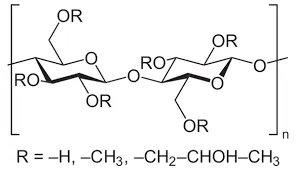

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has garnered significant attention in the construction and building materials industry, particularly in the formulation of wall putty. This article explores the role of HPMC in wall putty, its benefits, and its applications, providing insights necessary for professionals in construction and material science.

What is HPMC?

HPMC is a non-ionic, water-soluble polymer derived from cellulose, a natural polymer found in the cell walls of plants. It is modified to enhance its properties, including adhesion, water retention, and film-forming ability. This makes HPMC a crucial additive in various industrial applications, particularly in construction materials like wall putty.

Role of HPMC in Wall Putty

Wall putty is a white cement-based material used to achieve a smooth finish on interior and exterior walls. The addition of HPMC to wall putty formulations provides several advantages that enhance performance and application characteristics.

1. Improved Workability HPMC acts as a thickener, improving the viscosity of the wall putty mix. This ensures better application, allowing workers to spread the material evenly without it sagging or dripping. The enhanced flow properties reduce the effort required during application, making it easier and more efficient for laborers.

2. Water Retention One of the most remarkable properties of HPMC is its ability to retain water. This is particularly important in wall putty as it helps maintain adequate moisture content during the drying process. Proper water retention prevents premature drying, which can lead to cracking and surface defects. This feature also allows for extended working times, giving applicators more flexibility while working with the material.

3. Adhesion Properties HPMC improves the adhesion of wall putty to various substrates, including cement, brick, and plaster surfaces. Enhanced adhesion ensures that the putty stays intact over time, preventing peeling or flaking, which is vital for long-lasting finishes.

hpmc for wall putty

4. Flexibility and Durability The incorporation of HPMC in wall putty formulations enhances the flexibility of the cured product. This flexibility is essential in accommodating minor movements in building structures, reducing the risk of cracks. Additionally, HPMC contributes to the durability of the wall putty, ensuring a longer lifespan and better resistance to environmental stressors.

5. Eco-Friendly Option HPMC is derived from natural cellulose and is generally considered environmentally friendly. Its use in construction materials like wall putty contributes to more sustainable building practices, appealing to environmentally conscious consumers and builders alike.

Applications of HPMC-Based Wall Putty

The applications of HPMC-enhanced wall putty are numerous. It is widely used in both residential and commercial buildings, serving as a finishing layer on walls before painting or wallpapering. The smooth surface achieved with wall putty makes it ideal for achieving high-quality paint finishes, enhancing the overall aesthetic appeal of interiors and exteriors.

Furthermore, HPMC-based wall putty is often employed in restoration projects where maintaining the original aesthetic is crucial. Its superior adhesion and flexibility make it suitable for repairing walls and providing a smooth base for subsequent layers.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) plays a vital role in enhancing the performance of wall putty through its unique properties, including improved workability, water retention, adhesion, flexibility, and durability. As the construction industry continues to evolve, the demand for high-performance materials like HPMC-based wall putty will only increase.

By understanding the benefits and applications of HPMC in wall putty formulations, construction professionals can make informed decisions that contribute to the quality and longevity of their projects. The adoption of HPMC not only ensures better performance in wall finishes but also aligns with the growing trend towards sustainable and eco-friendly building practices.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025