Nov . 27, 2024 19:36 Back to list

HPMC Application in Wall Putty for Improved Texture and Performance

HPMC for Wall Putty Enhancing Performance and Durability

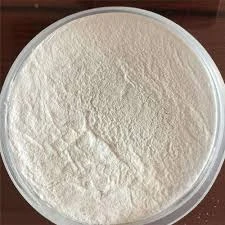

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has garnered significant attention in the construction industry, especially regarding its applications in wall putty. This water-soluble polymer plays a crucial role in enhancing the performance characteristics of wall putty, contributing to a smoother finish and improved durability. In this article, we will explore the benefits and applications of HPMC in wall putty formulations, shedding light on its importance in contemporary construction practices.

What is Wall Putty?

Wall putty is a white cement-based material used to create a smooth, even surface on walls before the application of paints or other finishing materials. The primary purpose of wall putty is to fill imperfections, cracks, and surface irregularities, resulting in a more aesthetically pleasing surface. However, the effectiveness of wall putty depends significantly on its formulation, which is where HPMC comes into play.

Role of HPMC in Wall Putty

1. Improved Workability One of the primary benefits of incorporating HPMC into wall putty is its ability to enhance workability. HPMC provides a creamy texture that allows for easy application and spreading, reducing the effort required for finishing. This ease of use is particularly beneficial for contractors and DIY enthusiasts, leading to quicker project turnaround times.

2. Water Retention HPMC is known for its excellent water retention properties. When added to wall putty, it helps retain moisture during the curing process. This is crucial for ensuring that the putty adheres properly to the substrate and cures uniformly, thereby reducing the risk of cracking and ensuring a strong bond between the putty and the wall surface.

hpmc for wall putty

3. Adjustable Set Time The addition of HPMC allows formulators to adjust the set time of wall putty. Depending on the specific requirements of a project, manufacturers can create products with different drying times, making it easier to accommodate various working conditions and preferences. This flexibility is essential for achieving optimal results in different environmental scenarios.

4. Enhanced Adhesion HPMC improves the adhesion properties of wall putty to various substrates, including concrete, plasterboard, and brick. With better adhesion, the risk of delamination or peeling of the putty is significantly minimized. This not only enhances the durability of the finish but also prolongs the lifespan of the applied surface.

5. Anti-Sagging Properties When applied in thicker layers, wall putty can sometimes sag or slump, leading to an uneven surface. HPMC helps mitigate this issue by providing thixotropic behavior, which prevents the putty from slumping, ensuring that it remains in place during application.

Applications Beyond Wall Putty

While HPMC is widely recognized for its role in wall putty, its applications extend beyond this specific use. It is also commonly found in other construction materials, such as tile adhesives, cement-based repair mortars, and texture coatings. The multifunctional properties of HPMC make it an indispensable ingredient in modern construction.

Conclusion

In conclusion, Hydroxypropyl Methylcellulose (HPMC) plays a vital role in enhancing the performance and durability of wall putty. Its ability to improve workability, water retention, adhesion, and anti-sagging properties makes it a valuable addition to wall putty formulations. As the construction industry continues to evolve, the demand for high-performance materials will persist, and HPMC is well-positioned to meet these needs. For contractors and builders aiming to deliver high-quality finishes, the incorporation of HPMC in wall putty is a logical and effective choice, ultimately contributing to the aesthetic appeal and longevity of construction projects. As such, HPMC stands out as a key ingredient that not only elevates the performance of wall putty but also enhances the overall quality of construction materials in the industry.

-

Premium Cellulose Ether: Effective Liquid Thickener & Stabilizer

NewsAug.31,2025

-

HPMC for Tile Adhesive: Superior Bonding & Workability

NewsAug.30,2025

-

Premium Cellulose Ether: Effective Liquid Thickener Solutions

NewsAug.29,2025

-

HPMC for Tile Adhesive: Enhanced Bonding & Workability

NewsAug.28,2025

-

tile-bonding-additives-for-stronger-bonds

NewsAug.22,2025

-

construction-grade-rdp-for-wholesale-needs

NewsAug.22,2025