Dec . 05, 2024 02:54 Back to list

hpmc for mortar

HPMC for Mortar Enhancing Performance and Versatility in Construction

Hydroxypropyl Methylcellulose (HPMC) has become an essential additive in the construction industry, especially in the formulation of mortar. This water-soluble polymer plays a crucial role in improving the properties of mortar mixtures, resulting in enhanced performance and versatility for various applications. In this article, we will explore the significant benefits of using HPMC in mortar, its applications, and its impact on the construction industry.

The Role of HPMC in Mortar

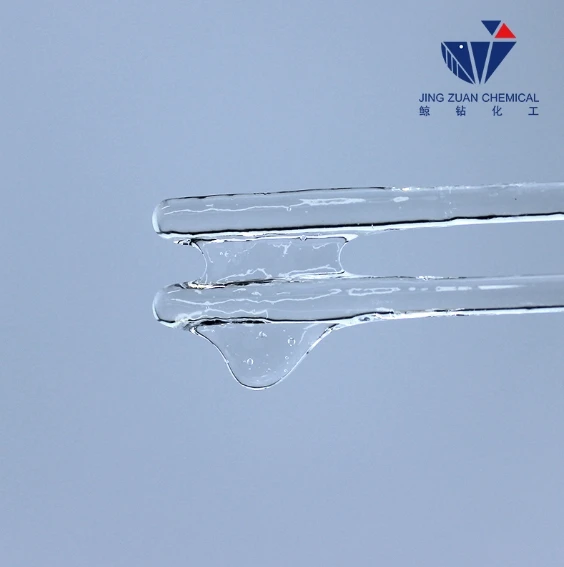

HPMC is derived from cellulose, a natural polymer found in plant cell walls. It possesses unique characteristics, including water retention, improved workability, adhesion, and thickening properties, making it an ideal additive for mortars. When mixed with mortar, HPMC enhances the overall quality of the final product, allowing for better performance in a wide range of construction applications.

Benefits of Using HPMC in Mortar

1. Improved Workability One of the primary advantages of HPMC is that it improves the workability of mortar. This enhancement allows construction workers to apply the mortar more easily, ensuring a smooth and consistent application. The workability also allows more extended open times, giving workers additional time to adjust and position materials as needed.

2. Water Retention HPMC contributes to excellent water retention properties, which is crucial for ensuring that the mortar cures correctly. The polymer helps retain moisture within the mortar mix, preventing premature drying, which can lead to cracks and reduced durability. This is particularly beneficial in hot and arid climates where evaporation can occur rapidly.

3. Enhanced Adhesion HPMC also enhances the adhesion properties of mortar. This improvement is vital for ensuring that the mortar bonds effectively with substrates, such as bricks, blocks, and stones. The increased adhesion results in stronger and more durable constructions, which can withstand various environmental stresses.

4. Versatility in Applications HPMC can be used in a wide array of mortar types, including cement-based mortars, tile adhesives, repair mortars, and thin-set mortars. Its versatility makes it a popular choice among construction professionals who seek to improve performance across different applications.

hpmc for mortar

5. Reduced Shrinkage and Cracking By promoting better moisture retention and workability, HPMC can help reduce shrinkage and cracking in hardening mortar. This characteristic is particularly important for thin applications where the risk of cracking is higher.

Applications in the Construction Industry

The use of HPMC in mortar extends across various sectors in the construction industry. It is commonly used in

- Tile Adhesives HPMC enhances the performance of tile adhesives, providing excellent bonding properties and flexibility, which are crucial for ensuring that tiles remain securely attached over time.

- Repair Mortars In repair applications, HPMC helps create a more workable mix that adheres well to existing surfaces, ensuring a durable repair that blends seamlessly with the original material.

- Render and Plaster HPMC improves the application and finish of renders and plasters, allowing for smoother and more consistent surfaces while minimizing the chances of cracking during drying.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) has revolutionized the way mortar is formulated and applied in the construction industry. Its unique properties bring numerous benefits, including improved workability, water retention, adhesion, and reduced shrinkage. As construction projects become more demanding, the use of HPMC in mortar continues to grow, providing solutions that meet the needs of modern construction while enhancing the quality and longevity of structures. By incorporating HPMC into mortar formulations, construction professionals can ensure more sustainable, reliable, and versatile outcomes, thereby contributing to the overall success of their projects.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025