Dec . 22, 2024 01:10 Back to list

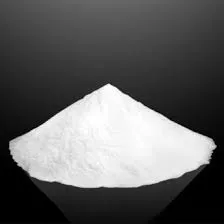

hpmc excipient

The Role of HPMC Excipients in Pharmaceutical Formulations

Hydroxypropyl methylcellulose (HPMC) is a cellulose-derived polymer widely used as an excipient in the pharmaceutical industry. As a versatile ingredient, HPMC plays a crucial role in various dosage forms, including tablets, capsules, and topical formulations. This article explores the properties, applications, and advantages of HPMC as an excipient.

Understanding HPMC

HPMC is a semi-synthetic polymer obtained by the chemical modification of cellulose, which is a natural polymer derived from plant cell walls. This modification involves the substitution of hydroxyl groups in cellulose with hydroxypropyl and methoxy groups, resulting in a water-soluble polymer with unique properties. HPMC is characterized by its ability to form gels, its film-forming capacity, and its biodegradability, making it an attractive choice for pharmaceutical applications.

Properties of HPMC

The primary properties that make HPMC an excellent excipient include

1. Solubility HPMC is soluble in cold water, which helps to create clear solutions. This solubility aids in the formulation of oral and topical products where clarity is crucial.

2. Viscosity The viscosity of HPMC solutions can be adjusted by altering the degree of substitution and the molecular weight of the polymer. This property is essential for thickening agents and stabilizers in various formulations.

3. Film-Forming Ability HPMC can form flexible, non-brittle films, making it ideal for sustaining drug release in controlled-release formulations, as well as for coating tablets and granules.

4. Biocompatibility As a biocompatible polymer, HPMC is well-accepted by the body, making it suitable for use in both localized and systemic drug delivery systems.

5. Stability HPMC is stable under a range of pH values and temperatures, ensuring that formulations maintain their efficacy and shelf life.

Applications of HPMC in Pharmaceuticals

HPMC is utilized in various pharmaceutical applications, including

hpmc excipient

1. Tablet Formulation HPMC is prominently used as a binder in tablet formulations. It provides a cohesive matrix that enhances tablet integrity and ensures uniform distribution of active pharmaceutical ingredients (APIs). Additionally, its film-forming nature makes it useful for tablet coatings.

2. Controlled-Release Systems HPMC's gel-forming properties are harnessed in controlled-release formulations. It helps regulate the release rate of drugs, enhancing therapeutic efficacy while minimizing side effects. This technology is particularly beneficial for medications that require a consistent release profile over time.

3. Suspensions and Emulsions In liquid formulations, HPMC serves as a suspending and thickening agent. Its ability to provide viscosity helps stabilize suspensions, preventing sedimentation of solid particles in liquid. This stabilizing property is essential for ensuring uniform dosage in suspensions.

4. Topical Formulations HPMC is widely used in gels and ointments due to its skin-friendly nature and film-forming capabilities. It provides a smooth application and enhances the sensory profile of topical products.

5. Ophthalmic Formulations In eye drop formulations, HPMC is utilized for its lubricating properties, helping alleviate dry eyes and improve patient comfort. Its viscoelastic properties support the retention of the solution on the surface of the eye.

Advantages of Using HPMC

The advantages of incorporating HPMC as an excipient in pharmaceutical formulations include

- Versatility Its multifunctional properties make HPMC suitable for a wide range of applications, making formulation development easier.

- Improved Bioavailability HPMC can enhance the solubility of poorly water-soluble drugs, improving their bioavailability and therapeutic effects.

- Regulatory Acceptance HPMC is generally recognized as safe (GRAS) and has a long-standing history of use in pharmaceuticals, facilitating its acceptance by regulatory authorities.

Conclusion

In conclusion, HPMC is a vital excipient in modern pharmaceutical formulations, offering a combination of desirable properties that enhance drug delivery and patient compliance. Its versatility, stability, and compatibility make it an essential component in the development of innovative drug delivery systems. As the pharmaceutical industry continues to evolve, the application of HPMC in new formulations will likely expand, contributing to advancements in therapeutic strategies and patient care.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025