Sep . 29, 2024 01:01 Back to list

Exploring HPMC Density Variations and Their Impact on Material Properties

Understanding HPMC Density and Its Implications

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative widely used in various industries, including pharmaceuticals, food, and construction. One of the critical properties of HPMC that researchers and manufacturers closely monitor is its density, which plays a significant role in determining its application effectiveness, formulation stability, and overall performance.

What is HPMC?

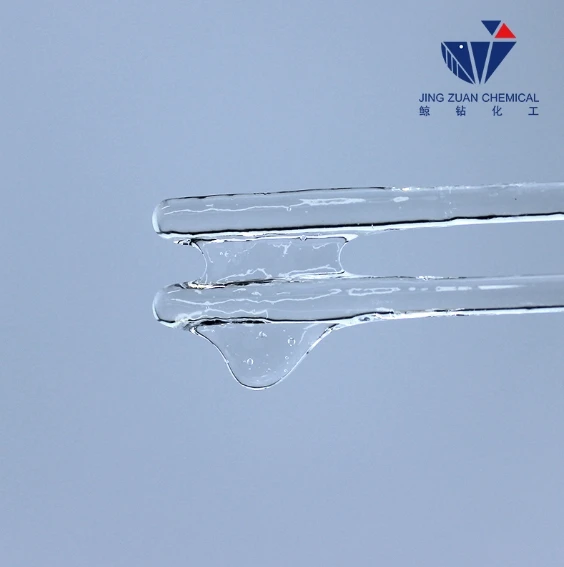

HPMC is a white, odorless powder that is soluble in cold water. It is derived from cellulose, a natural polymer found in plant cell walls. This modification process incorporates hydroxypropyl and methyl groups into the cellulose structure, enhancing its versatility and functionality. HPMC is known for its thickening, emulsifying, and film-forming properties, making it a valuable ingredient in various formulations.

The Importance of Density in HPMC

Density, defined as mass per unit volume, is a fundamental physical property that influences how a substance behaves in different formulations and environments. In the case of HPMC, its density can significantly impact several key aspects

1. Formulation Stability The density of HPMC can affect the stability of formulations. A higher density may lead to sedimentation in liquid formulations, while a lower density can facilitate easy dispersion and homogeneity. Understanding the density allows formulators to adjust the concentration of HPMC to achieve the desired consistency and stability.

2. Viscosity Density is closely related to viscosity, which is a measure of a fluid's resistance to flow. In formulations where HPMC is used as a thickener, its density can influence the overall viscosity of the product. A higher density often corresponds to increased viscosity, thus enhancing the product's texture and mouthfeel in food applications or improving the spreadability in pharmaceutical creams.

3. Release Rate In pharmaceutical formulations, particularly those that are controlled-release or sustained-release systems, the density of HPMC can affect the drug release profile. HPMC with different densities can modulate the rate at which a drug is released into the system, ensuring that therapeutic effects are delivered effectively and consistently.

hpmc density

4. Mechanical Properties For applications in construction and coatings, such as in tile adhesives and paints, the density of HPMC plays a crucial role in the mechanical properties of the final product. It affects the adhesion, workability, and durability of these materials, which are paramount for ensuring the longevity and effectiveness of construction projects.

5. Formulation Cost-Effectiveness Knowing the density of HPMC can aid manufacturers in optimizing their formulations to minimize costs. By understanding how different densities impact the properties of the final product, formulators can make informed decisions about HPMC quantities to use, thus maximizing efficiency and cost-effectiveness.

Methods for Determining HPMC Density

Researchers use various methods to determine the density of HPMC, including

- Bulk Density Measurement This method involves measuring the mass of a specific volume of HPMC powder in its bulk state. It helps assess how the powder will behave during storage and handling.

- Tapped Density Measurement By tapping a sample to allow it to settle, manufacturers can determine the maximum packing density of HPMC, which is particularly useful for predicting how it will perform in formulations.

- Apparent Density Measurement This provides insights into the density of HPMC in its dispersed or suspended state, which is critical for liquid formulations.

Conclusion

In conclusion, HPMC density is a key parameter that plays an influential role in its functionality across various applications. Understanding its implications can lead to better formulation practices, improved product efficiency, and enhanced user experiences. As industries continue to innovate, the significance of HPMC density will remain a cornerstone of research and application in ensuring that products meet the necessary standards for performance and safety.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025