Oct . 22, 2024 06:46 Back to list

HPMC and CMC Exploring Their Uses and Benefits in Various Applications

Exploring the Significance of HPMC and CMC in Modern Applications

Hydroxypropyl methylcellulose (HPMC) and carboxymethyl cellulose (CMC) are two essential cellulose derivatives that have gained prominence across various industries due to their unique chemical properties and functional versatility. These biopolymers are derived from natural cellulose, offering a wide range of applications in pharmaceuticals, food, cosmetics, and construction.

Understanding HPMC and Its Applications

HPMC is a highly purified, non-ionic cellulose ether that is primarily used as a thickening, binding, and film-forming agent. Its solubility in cold water and its ability to form gels upon heating make it an ideal additive in many formulations. In the pharmaceutical industry, HPMC is widely utilized in the production of sustained-release drug formulations. Its controlled-release properties optimize therapeutic effects while minimizing side effects, making it a valuable excipient in oral drug delivery systems.

.

The construction industry also benefits from HPMC, where it is used as a drier and binder in mortars and plasters. It improves workability, allows for extended open time, and enhances water retention, leading to better adhesion and durability of building materials.

hpmc cmc

The Versatility of CMC

Similar to HPMC, carboxymethyl cellulose (CMC) is another cellulose derivative renowned for its thickening, gelling, and stabilizing properties. CMC is an anionic polymer that readily dissolves in water, forming viscous solutions. This characteristic makes it a popular choice in the food industry, where it is used as a food additive. CMC acts as a thickener, stabilizer, and emulsifier, improving the texture and mouthfeel of various products, including ice cream, salad dressings, and sauces.

In the pharmaceutical field, CMC serves as a binder in tablet formulations and as a controlled-release agent. Its ability to swell in water helps regulate the release of active ingredients, ensuring prolonged therapeutic effects. Furthermore, CMC is often used in ocular formulations as a lubricant in eye drops, providing relief from dry eyes and enhancing comfort for users.

The cosmetic industry also extensively utilizes CMC, where its thickening and emulsifying properties enhance the stability and aesthetics of creams and lotions. CMC's excellent water retention and film-forming abilities also allow it to be used in hair care products, providing smoothness and moisture retention.

Conclusion

HPMC and CMC exemplify the innovative application of cellulose derivatives in modern industries. Their multifunctional properties make them invaluable components in pharmaceuticals, food products, cosmetics, and construction materials. As industries continue to seek sustainable and effective solutions, the relevance of these biopolymers is expected to grow. Advances in research and technology may also unlock new applications of HPMC and CMC, further cementing their status as essential materials in various sectors. Understanding and leveraging the capabilities of HPMC and CMC will undoubtedly lead to improved product formulations and enhanced consumer experiences across the board.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

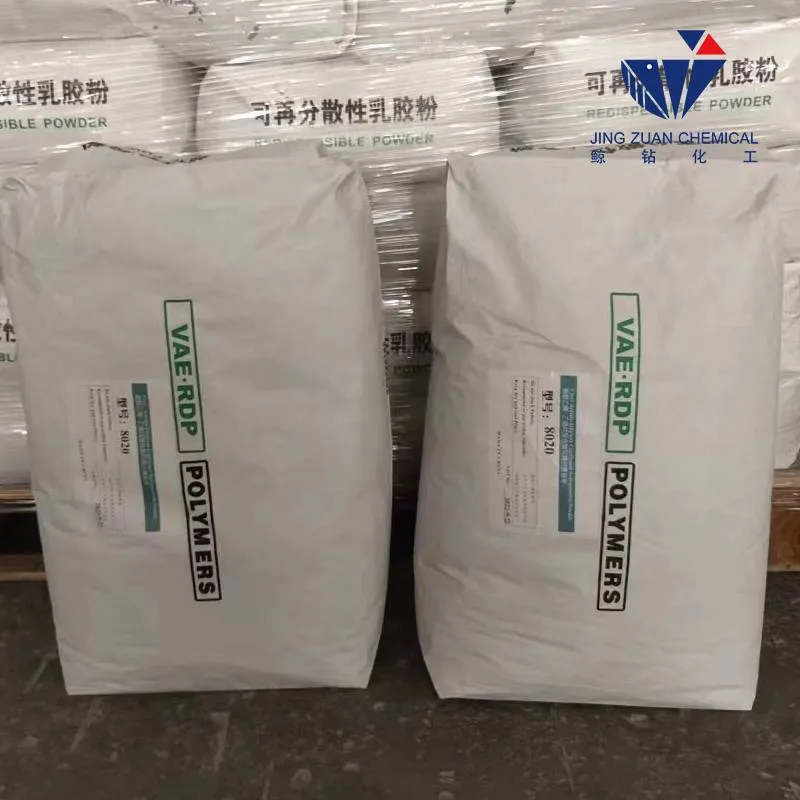

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025