Dec . 05, 2024 00:04 Back to list

hpmc cellulose

Understanding HPMC Cellulose A Versatile Polymer for Various Applications

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic polymer derived from cellulose, a natural polymer found in the cell walls of plants. This cellulose ether is widely utilized in numerous industries, including pharmaceuticals, food, construction, and cosmetics, owing to its unique properties and versatility.

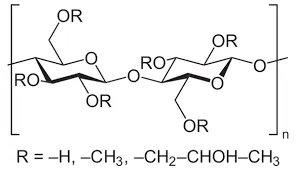

Chemical Structure and Properties

HPMC is created by modifying cellulose through hydroxypropyl and methyl substitutions. These modifications enhance its solubility in water and expand its functional applications. The degree of hydroxypropyl and methyl substitution can be tailored during the manufacturing process, resulting in various grades of HPMC, each with distinct characteristics suitable for different applications.

One of the prominent properties of HPMC is its ability to form gels and films when mixed with water, making it an excellent thickening agent. Additionally, it possesses excellent rheological properties, enabling it to modify the viscosity of solutions and improve the texture of products. HPMC is non-toxic, biocompatible, and has low allergenic potential, making it a preferred choice for applications in sensitive environments, such as pharmaceuticals and food products.

Applications in Pharmaceuticals

In the pharmaceutical industry, HPMC plays a crucial role as a binder, filler, and coating agent in the formulation of tablets and capsules. Its gel-forming properties help in controlling the release of active ingredients, allowing for sustained-release formulations that improve patient compliance. HPMC is also used in ophthalmic formulations for eye drops, where it acts as a lubricant to relieve dryness and irritation.

Moreover, HPMC is employed in the production of hydrogel dressings and wound care products. The polymer's moisture-retentive capabilities facilitate an optimal healing environment by promoting hydration and ensuring effective drug delivery to the affected area.

hpmc cellulose

Role in Food Products

HPMC's versatility extends to the food industry, where it is used as a stabilizer, emulsifier, and thickener. It aids in improving the texture and mouthfeel of various food products, including sauces, dressings, and baked goods. As a fat replacer, HPMC can help reduce caloric content while maintaining product quality. Since it is derived from natural cellulose, it is generally regarded as safe (GRAS) by regulatory authorities, making it a desirable ingredient in food formulation.

Construction and Cosmetic Applications

In the construction industry, HPMC is valued for its water-retention properties, which enhance the workability and adhesion of cement-based materials. It is commonly incorporated into tile adhesives, plasters, and other building materials to improve performance and durability. Its ability to form a film also provides water resistance, which is essential for long-lasting construction materials.

In cosmetics, HPMC serves as a stabilizer, thickener, and film-forming agent in various formulations, including creams, gels, and lotions. Its non-irritating nature makes it suitable for sensitive skin formulations, while its ability to emulsify ensures stability in products where oils and water are combined.

Conclusion

HPMC cellulose is a remarkable polymer with a multitude of applications across diverse industries. Its unique properties, such as gel formation, viscosity modification, and non-toxic nature, make it a vital ingredient in pharmaceuticals, food products, construction materials, and cosmetics. As research continues to uncover new applications for HPMC, its role in enhancing product formulations and improving functionality will only expand, paving the way for innovative solutions in various fields.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025