Nov . 25, 2024 15:29 Back to list

HPMC Supplier for High-Quality Hydroxypropyl Methyl Cellulose Products and Applications

Understanding HPMC The Versatile Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose (HPMC) is a cellulose derivative that has gained significant importance in various industries, including pharmaceuticals, food, cosmetics, and construction. As a non-ionic, water-soluble polymer, HPMC stands out due to its unique properties, making it a preferred choice for manufacturers globally. In this article, we will explore the characteristics, applications, and benefits of HPMC, as well as the critical role of HPMC manufacturers.

What is HPMC?

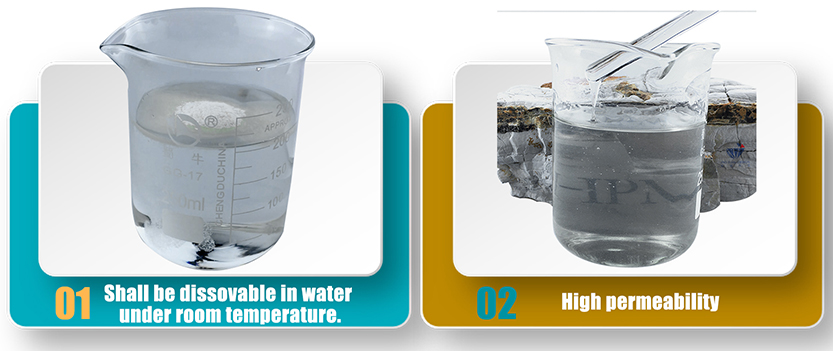

HPMC is synthesized through the chemical modification of cellulose, a natural polymer derived from plant cell walls. The process involves the substitution of hydroxyl groups in cellulose with hydroxypropyl and methyl groups, a transformation that endows HPMC with its unique properties. Its structure contains both hydrophilic and hydrophobic segments, allowing it to interact with water, organic solvents, and a range of other materials.

The resulting polymer exhibits excellent water retention, film-forming capabilities, and thickening properties, making it an essential ingredient in a myriad of formulations. HPMC is available in various grades, differing in viscosity, molecular weight, and degree of substitution, which allows manufacturers to tailor its use according to specific applications.

Applications of HPMC

1. Pharmaceuticals In the pharmaceutical industry, HPMC serves multiple functions. It acts as a binder in tablet formulations, ensuring a uniform distribution of APIs (active pharmaceutical ingredients). HPMC is also widely used in controlled-release formulations, where its gel-forming ability helps regulate the release of medications over time. Moreover, it can enhance the stability and bioavailability of drugs, making it a valuable excipient in pharmaceutical development.

2. Food Industry HPMC is recognized for its ability to improve the texture and stability of food products. It is commonly used as a thickening and gelling agent in sauces, dressings, and baked goods. Additionally, HPMC can act as a fat replacer, contributing to lower-calorie food formulations. Its emulsifying properties help maintain the consistency of various food products, ensuring a pleasurable eating experience.

3. Cosmetics and Personal Care In cosmetics, HPMC serves as a thickener and stabilizer in creams, lotions, and gels. Its film-forming properties help enhance the sensory feel of products, providing a smooth and luxurious application experience. HPMC is also used in hair care products to provide styling hold and improve conditioning effects.

4. Construction HPMC is increasingly utilized in the construction sector, particularly in the formulation of cement-based materials. Its water-retention properties help improve the workability and performance of mortars and plasters. HPMC enhances adhesion, reduces cracking, and improves the overall durability of construction materials.

Benefits of HPMC

The versatility of HPMC comes with an array of benefits that make it appealing to manufacturers

hpmc-hydroxypropyl methyl cellulose manufacturer

- Non-toxic and Safe HPMC is considered non-toxic and safe for use in food and pharmaceutical applications. Its compliance with regulatory standards makes it a reliable choice for sensitive formulations. - Customization With multiple grades available, manufacturers can customize HPMC to meet specific requirements. This flexibility allows for optimal performance across diverse applications.

- Enhanced Stability HPMC contributes to the stability of formulations, helping prevent phase separation and improving shelf life.

- Ease of Use HPMC is easy to handle and can be incorporated into formulations without complex processing steps.

- Cost-effective The use of HPMC can lead to cost-effective formulations, as it helps enhance product performance while reducing the need for additional ingredients.

Choosing an HPMC Manufacturer

When selecting an HPMC manufacturer, it is essential to consider several factors

- Quality Assurance Ensure that the manufacturer follows stringent quality control measures and complies with relevant industry standards.

- Technical Support A reputable manufacturer should offer technical support and guidance on HPMC formulations and applications.

- Research and Development Consider manufacturers that invest in R&D to enhance product offerings and innovate new solutions.

- Reputation and Experience A manufacturer with a solid track record and extensive experience in the industry is likely to provide reliable products and services.

Conclusion

Hydroxypropyl Methylcellulose is a remarkable polymer with diverse applications across multiple industries. Its unique properties offer significant advantages, making it a vital ingredient for many products. As the demand for HPMC continues to grow, partnering with a trusted HPMC manufacturer becomes increasingly essential for businesses seeking to enhance their formulations and deliver high-quality products to the market.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025