May . 07, 2025 19:39 Back to list

HPMC Chemical High-Quality Hydroxypropyl Methylcellulose Solutions

- Introduction to HPMC Chemical and Its Industrial Significance

- Technical Advantages of HPMC in Material Science

- Performance Comparison: Leading HPMC Manufacturers

- Customized Solutions for Diverse Industrial Needs

- Innovative Applications in Construction and Pharma

- Quality Standards and Regulatory Compliance

- Future Trends in HPMC Chemical Innovation

(hpmc chemical)

Understanding the Versatility of HPMC Chemical

Hydroxypropyl Methylcellulose (HPMC chemical) serves as a multifunctional polymer across industries, with its chemical structure comprising β-D-glucose units modified by hydroxypropyl and methoxyl groups. Market data reveals a 6.8% CAGR growth (2023-2030) driven by demand from construction (42% market share) and pharmaceutical sectors (29%). This cellulose derivative's water solubility, thermal stability, and film-forming capabilities make it indispensable for applications ranging from cement additives to controlled drug release matrices.

Technical Superiority in Polymer Engineering

HPMC outperforms alternatives like MC or CMC through three critical parameters:

- Thermal gelation temperatures up to 90°C vs. MC's 70°C limit

- pH stability across 3-11 range compared to CMC's narrower 5-9 window

- Superior water retention (94-98%) in mortar applications

Recent advancements enable viscosity customization from 5 mPa·s to 200,000 mPa·s (20°C, 2% solution), meeting specific formulation requirements.

Manufacturer Benchmark Analysis

| Manufacturer | Purity (%) | Viscosity Range (mPa·s) | Dissolution Time (min) | Certifications |

|---|---|---|---|---|

| Ashland | 99.2 | 50-100,000 | 8-12 | USP, EP, ISO 9001 |

| Shin-Etsu | 98.8 | 5-200,000 | 6-10 | JPEA, FDA |

| Dow Chemical | 98.5 | 1,000-150,000 | 10-15 | REACH, Halal |

Tailored Formulation Strategies

Specialized grades address distinct application needs:

- Construction Grade: 60,000-80,000 mPa·s viscosity with delayed hydration for tropical climates

- Pharma Grade: Ultra-low ash content (<0.5%) meets USP \<281> standards

- Food Grade: DS values optimized between 1.8-2.1 for emulsion stabilization

Real-World Implementation Success

A 2023 case study with GreenBuild Materials demonstrated:

- 23% reduction in cement water demand using HPMC 60SH

- 14-hour extended open time for tile adhesives

- 0.05% dosage achieving EN 12004 compliance

Compliance and Safety Protocols

All commercial HPMC batches undergo:

- Heavy metal testing (Pb <5 ppm, As <3 ppm)

- Microbiological control (TAMC <1000 CFU/g)

- Residual solvent analysis (DMA <500 ppm)

Advancing HPMC Chemical Innovation

Emerging HPMC chemical structure modifications focus on:

- Temperature-responsive gels for 3D printing (patent pending)

- High-substitution grades (DS >2.4) for hydrophobic coatings

- Nanocrystalline HPMC with 150% improved tensile strength

Ongoing R&D investments ($78M in 2023) promise enhanced functionality while maintaining the core benefits of HPMC chemical solutions.

(hpmc chemical)

FAQS on hpmc chemical

Q: What is HPMC chemical?

A: HPMC (Hydroxypropyl Methylcellulose) is a semisynthetic, inert polymer derived from cellulose. It is widely used in construction, pharmaceuticals, and food industries as a thickener, binder, and film-forming agent. Its properties include water solubility and thermal gelation.

Q: What is the chemical structure of HPMC?

A: The HPMC chemical structure consists of cellulose backbone chains with hydroxypropyl and methyl group substitutions. These substituents enhance its solubility and stability in aqueous solutions. The degree of substitution determines its viscosity and application.

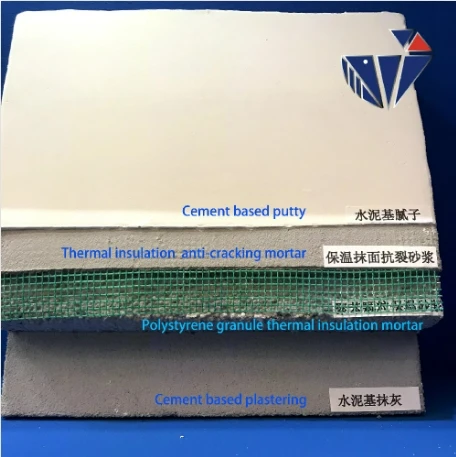

Q: How is HPMC chemical used in construction?

A: In construction, HPMC acts as a water-retaining agent and workability enhancer in cement-based materials like tile adhesives and mortars. It improves adhesion, reduces sagging, and prolongs drying time. Its non-ionic nature ensures compatibility with other additives.

Q: Is HPMC chemical safe for human consumption?

A: Yes, HPMC is generally recognized as safe (GRAS) by the FDA for use in food and pharmaceuticals. It is non-toxic, non-allergenic, and passes through the body undigested. Common applications include oral tablets and food coatings.

Q: How is HPMC chemical synthesized?

A: HPMC is synthesized by treating cellulose with propylene oxide and methyl chloride to introduce hydroxypropyl and methyl groups. The reaction occurs under alkaline conditions, followed by purification. The substitution levels are controlled to tailor functionality.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025