Nov . 19, 2024 07:31 Back to list

how to dissolve hpmc in water

How to Dissolve HPMC in Water

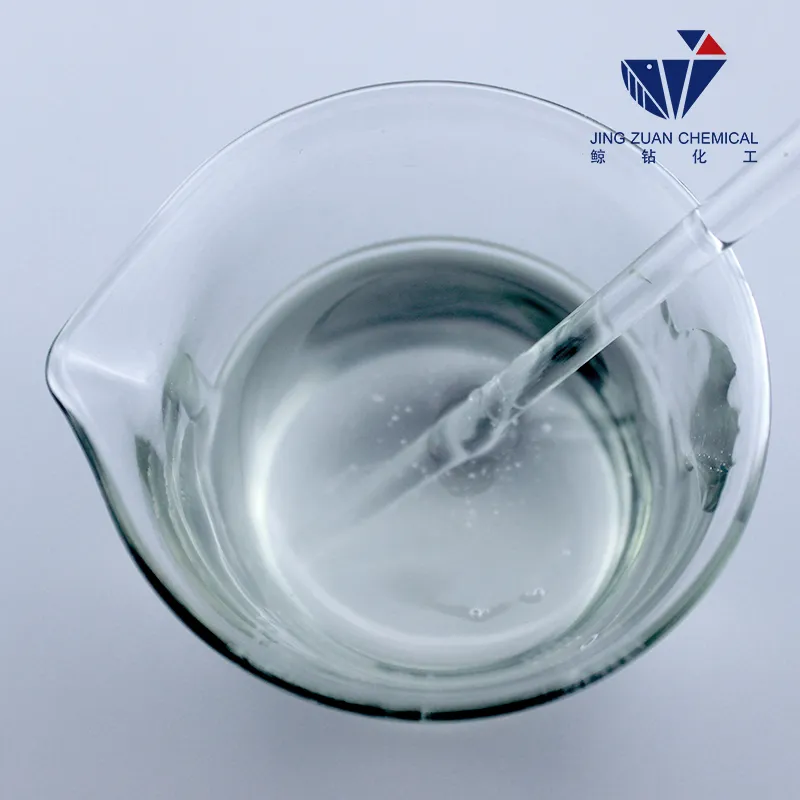

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that finds extensive applications in various industries, including pharmaceuticals, construction, food, and cosmetics. Its unique properties, such as film-forming, thickening, and water-retaining abilities, make it a preferred choice for many formulations. However, properly dissolving HPMC in water can be a challenge for some users, particularly those who are new to working with this material. This article will guide you through the process of effectively dissolving HPMC in water, ensuring that you achieve a smooth, homogeneous solution.

Understanding HPMC

Before diving into the dissolution process, it is essential to understand HPMC. HPMC is a white, odorless powder that is hydrophilic, meaning it readily interacts with water. However, due to its molecular structure, it does not dissolve easily when added directly to water. Instead, certain techniques must be employed to facilitate its dissolution and avoid clumping.

Step-by-Step Guide to Dissolving HPMC

1. Choosing the Right Water Temperature

One critical factor that influences the dissolution of HPMC is the temperature of the water used. Generally, warm or hot water enhances the solubility of HPMC. The use of water heated to about 60-80 degrees Celsius (140-176 degrees Fahrenheit) can improve the dissolution process. However, ensure the water is not boiling, as excessive heat can degrade the HPMC.

When incorporating HPMC into water, it is essential to do so gradually to prevent clumping. Start by measuring the desired amount of HPMC powder—typically between 1% to 5% of the total water weight. Sprinkle the HPMC powder slowly over the surface of the water while continuously stirring. This technique helps to evenly distribute the particles and prevents the formation of lumps.

how to dissolve hpmc in water

3. Stirring and Hydration

Once the HPMC powder is added to the water, the next step is to stir vigorously. Using either a mechanical mixer or a hand whisk, mix the solution continuously for several minutes. It is important to maintain consistent agitation to keep the particles suspended and assist in the hydration process. Depending on the viscosity and concentration of the solution, the stirring time may vary. Typically, a stirring duration of 10-15 minutes is sufficient for most applications.

4. Allowing Time for Complete Dissolution

After stirring, let the mixture sit for a while. Even if it appears to have dissolved, allowing it to rest for an additional 30 minutes to an hour will enable any remaining undissolved particles to hydrate fully and disperse. During this time, you may periodically stir the mixture to ensure uniformity.

5. Adjusting Viscosity

If the final solution is too thick, you can adjust the viscosity by adding more water or by using lower concentrations of HPMC in future applications. On the other hand, if a thicker consistency is desired, consider increasing the amount of HPMC or allowing the solution to sit longer for further thickening through hydration.

Conclusion

Dissolving HPMC in water requires a careful approach to ensure optimal results. By following the outlined steps—choosing the appropriate water temperature, adding HPMC gradually, stirring thoroughly, allowing for rest, and adjusting viscosity as needed—you can achieve a smooth and effective HPMC solution for your specific applications. With practice and attention to detail, you will find it easier to work with HPMC, unlocking its full potential in your formulations.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025