Dec . 20, 2024 06:20 Back to list

High-Performance Coatings and Adhesives for Building Applications with HPMC

The Importance of HPMC in Building Coatings and Adhesives

Hydroxypropyl Methylcellulose (HPMC) has garnered significant attention in the construction sector, particularly in the formulation of building coatings and adhesives. As a versatile and effective additive, HPMC plays a crucial role in enhancing the performance characteristics of these materials, making them more efficient and reliable in various applications.

What is HPMC?

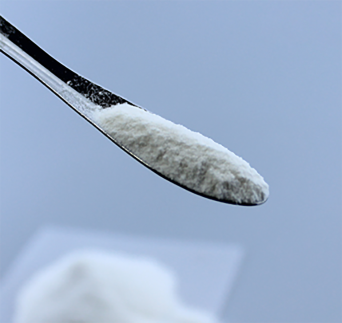

HPMC is a non-ionic cellulose ether derived from natural cellulose, which has undergone chemical modification to improve its solubility and performance. This white, odorless powder forms a gel when mixed with water, creating a viscous solution that can modify the texture and rheological properties of mixtures. Its unique structure imparts significant advantages in the construction industry.

Enhancing Adhesive Performance

One of the primary uses of HPMC in building coatings and adhesives is its ability to improve adhesion properties. When incorporated into adhesive formulations, HPMC enhances the bond strength, ensuring that materials remain securely joined even under challenging conditions. This is particularly important in construction projects, where structural integrity is paramount.

Furthermore, HPMC contributes to the flexibility of adhesives, allowing for movement and expansion without compromising the bond. This flexibility is essential in environments subject to temperature fluctuations and vibrations, where rigid adhesives may crack and fail over time.

Water Retention and Workability

Another significant advantage of HPMC is its excellent water retention properties. This feature is crucial during the application of adhesives and coatings, as it allows for extended working time. HPMC helps maintain the moisture content of the mixture, preventing premature drying. As a result, contractors have a more extended period to apply and manipulate the materials, which is especially beneficial for complex applications requiring precision.

building coating adhesive hpmc

Moreover, the smooth consistency provided by HPMC enhances the workability of mixtures. This ease of use not only speeds up the application process but also allows for better surface finish outcomes. Applicators can achieve a more uniform layer, reducing the likelihood of defects such as bubbles or streaks.

Improving Coating Properties

In building coatings, HPMC serves several critical functions. It acts as a thickener, improving the texture and consistency of the product, which is vital for achieving an even coverage. Additionally, HPMC can enhance the stability of the coating, preventing settling and ensuring that pigments remain uniformly distributed throughout the application.

The presence of HPMC also contributes to the shear-thinning property of coatings. This means that the viscosity decreases under shear stress during application, making it easier to spread the coating while still providing a thick, durable layer upon drying. This characteristic is particularly valuable in both spray and brush applications.

Environmental and Health Benefits

HPMC is considered a safer alternative to many traditional additives used in adhesives and coatings, as it is non-toxic and free from solvents. Its formulation does not release harmful gases, making it safer for use in occupied spaces, thereby aligning with growing consumer demand for environmentally friendly construction materials. This eco-friendly profile enhances its appeal among builders and architects committed to sustainable practices.

Conclusion

In summary, Hydroxypropyl Methylcellulose (HPMC) is an indispensable ingredient in building coatings and adhesives. Its multifaceted properties, including enhanced adhesion, superior water retention, improved workability, stability, and environmental safety, make it an ideal choice for modern construction practices. As the industry continues to evolve, the use of HPMC will likely expand, further solidifying its role as a key additive in producing high-performance building materials. The ongoing advancements in formulation technology will undoubtedly lead to even more innovative applications of HPMC, pushing the boundaries of construction material performance and sustainability.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025