Dec . 12, 2024 09:33 Back to list

building coating adhesive hpmc

The Role of Hydroxypropyl Methylcellulose (HPMC) in Building Coating Adhesives

In the realm of construction materials, the importance of high-performance coatings and adhesives cannot be overstated. Among the various additives that enhance the properties of these materials, Hydroxypropyl Methylcellulose (HPMC) stands out due to its exceptional functional attributes. This article explores the significance of HPMC in building coating adhesives, elaborating on its composition, benefits, and applications.

Understanding HPMC

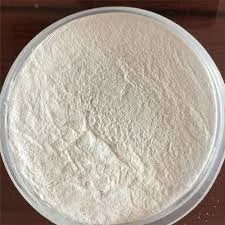

HPMC is a semi-synthetic polymer derived from cellulose, a natural polymer found in plant cell walls. Its chemical modifications confer a variety of beneficial properties, including improved water retention, viscosity modulation, and binding capabilities. HPMC is often found in powder form and is soluble in cold water, forming a clear, viscous solution. This versatility makes it an ideal additive in various construction applications, particularly in coatings and adhesives.

Advantages of Using HPMC in Building Coatings

1. Enhanced Workability One of the primary benefits of incorporating HPMC into building coatings and adhesives is its ability to improve workability. When mixed with other components, HPMC increases the viscosity of the formulation. This augmented viscosity allows for better control during application, minimizing the risk of sagging and ensuring an even spread on surfaces—critical factors in achieving a high-quality finish.

2. Water Retention Water retention is a crucial property in many building applications. HPMC acts as a water-retaining agent, ensuring that moisture remains in the mixture for an extended period. This characteristic is vital for cement-based coatings, as it allows for better hydration of the cement particles, leading to improved curing and ultimately enhancing the structural integrity and durability of the final product.

3. Adhesion Promotion Adhesion is paramount for coatings and adhesives to perform effectively. HPMC contributes to enhanced adhesion properties, ensuring that coatings bond securely to various substrates, including concrete, wood, and metal. The polymer's unique structure facilitates the formation of a strong interfacial bond, which contributes to the longevity and effectiveness of the coating.

4. Improved Stability Another significant advantage of HPMC in building coatings is its ability to stabilize emulsions. It helps maintain the consistency of the coating mix, preventing separation over time. This stability is critical during the storage and application phases, ensuring that the product retains its properties until it is used.

building coating adhesive hpmc

5. Environmental Friendliness With an increasing emphasis on sustainable construction practices, HPMC presents an environmentally friendly option. It is non-toxic and biodegradable, making it suitable for green building initiatives. Its use aligns with the growing demand for low-impact building materials that do not compromise on performance.

Applications in Building Coatings

HPMC is widely utilized in various building coating formulations, including

- Mortars HPMC enhances the performance of mortars by improving their workability, adhesion, and water retention, critical for tile adhesives and grouts. - Plaster and Render In plaster applications, HPMC helps achieve better application properties and improves the final finish by ensuring uniformity and consistency.

- Interior and Exterior Paints Incorporating HPMC into paint formulations boosts viscosity, allows for better application on vertical surfaces, and improves overall durability against environmental factors.

- Gypsum Products In gypsum board adhesives, HPMC ensures stronger bonding and aids in the drying process.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) is undeniably a vital ingredient in modern building coating adhesives. Its multifunctional properties enhance workability, water retention, adhesion, and stability, making it indispensable in achieving durable and high-performing coatings. As the construction industry continues to evolve towards sustainability and efficiency, the role of HPMC and similar additives will likely expand, helping to meet the future demands of building materials while contributing to greener construction practices. Whether in mortars, paints, or plaster, HPMC remains a key player in shaping the future of construction and building coatings.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025