Oct . 09, 2024 01:42 Back to list

Exploring Uses of Redispersible Polymer Powder in Various Industries and Applications

Applications of Redispersible Polymer Powder

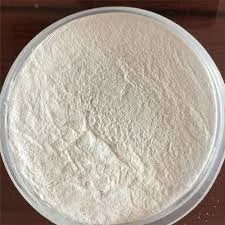

Redispersible polymer powder (RDP) has gained significant traction in the construction and building materials industry due to its versatile characteristics and performance-enhancing properties. This powdered polymer is primarily derived from emulsions, which are spray-dried into a fine powder. Upon re-dispersion in water, RDP offers unique benefits, making it a valuable additive in various applications.

One of the most prominent applications of RDP is in cement-based formulations. By incorporating RDP, manufacturers can enhance the adhesion properties of adhesives, grouts, and mortars. The polymer provides improved bonding between surfaces, reducing the likelihood of delamination and ensuring the longevity of constructions. This is particularly crucial in tiling applications, where strong adhesion is necessary to withstand mechanical stresses.

In addition to improved adhesion, RDP functions to enhance flexibility and workability in cementitious mixtures. In environments where temperature fluctuations and structural movements are common, the flexibility imparted by RDP can help mitigate cracking and other forms of damage. This property is vital for applications such as exterior wall systems and flooring, which are often subjected to dynamic stresses.

Moreover, RDP technology benefits thermal insulation materials. When added to insulation boards and renders, RDP improves the mechanical performance and resistance to thermal cycling. Such enhancements make these materials more effective in energy-efficient buildings, where maintaining stable indoor temperatures is a priority.

applications of redispersible polymer powder

Additionally, RDP is instrumental in developing diverse types of dry-mix mortars, which are pre-blended materials requiring only the addition of water at the job site. Usage of RDP in these dry mixes ensures consistent quality and enhances performance, resulting in fewer issues related to application and finished quality. This benefits both contractors and end-users, making construction processes smoother and more efficient.

In the realm of paints and coatings, redispersible polymer powders improve scrub resistance, adhesion, and flexibility while reducing the risk of chalking. This allows for the creation of durable exterior paints that can withstand environmental stressors. Furthermore, when incorporated into decorative coatings, RDP can facilitate the incorporation of various finishes and textures, increasing the aesthetic appeal of the final product.

RDP's utility extends beyond just the construction domain; it's also valuable in other applications, including sealants, adhesives, and even textiles. Its capacity to improve water resistance, elongation, and overall mechanical properties makes it a sought-after component in many formulations.

In conclusion, the applications of redispersible polymer powder are vast and varied across multiple industries, especially in construction. Its ability to enhance adhesion, flexibility, thermal resistance, and overall material performance solidifies RDP as a critical additive in modern building materials. As the demand for high-performance and sustainable construction products continues to grow, the role of RDP is likely to become even more prominent, offering innovative solutions to meet the evolving needs of the industry.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025