ag. . 05, 2025 10:45 Tornar a la llista

HPMC Factory Contributions to Liquid Detergents

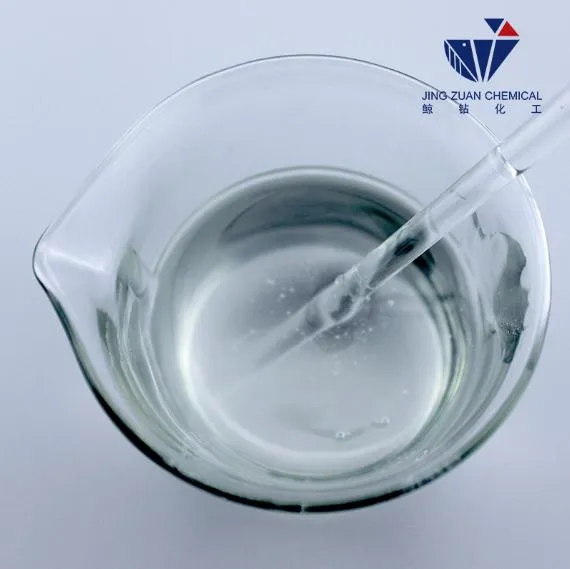

Liquid detergents rely on precise chemical engineering for optimal performance. HPMC factories play a pivotal role in this process, producing Hydroxypropyl Methyl Cellulose (HPMC) that transforms raw ingredients into high-performance cleaning agents. With over 15 years of expertise, facilities like Jingzuan Chemical Technology in Shijiazhuang (300 km from Beijing and Tianjin Port) supply specialized HPMC cellulose to global manufacturers. This article explores how China HPMC enhances viscosity control and stability in liquid detergents, driving industry innovation.

HPMC: Precision Viscosity Control in Liquid Detergents

Viscosity directly impacts a detergent's usability and effectiveness. HPMC serves as a multifunctional thickener, allowing manufacturers to fine-tune flow properties for diverse applications—from shampoos to dishwashing liquids. Its viscosity range (400–200,000 mPa.s) enables customization: higher viscosity creates luxurious, clingy formulations for body washes, while lower values facilitate easy-pouring dish soaps. The instant dissolving type dissolves rapidly in room-temperature water, simplifying production without compromising permeability. This adaptability stems from HPMC's molecular structure (C₃₆H₇₀O₁₉), which forms hydrogen bonds with water molecules to create consistent gel networks. For example, in laundry detergents, optimal viscosity ensures even fabric coverage, lifting stains without residue. Jingzuan's HPMC also acts as a dispersant, preventing ingredient separation during storage. Below are key parameters for detergent-grade HPMC:

|

Parameter |

Value Range |

Function in Detergents |

|

Viscosity |

400–200,000 mPa.s |

Adjusts thickness and flow |

|

Gel Temperature |

62–70°C |

Stabilizes emulsions during heating |

|

Moisture Content |

≤5% |

Prevents microbial growth |

|

Ash Residue |

≤5% |

Ensures purity and clarity |

HPMC Cellulose: Stabilizing Liquid Soap Formulations

Stability defines a detergent's shelf life and performance consistency. HPMC cellulose prevents phase separation by acting as an emulsifier and film-forming agent. Its hydrophilic chains bind water while hydrophobic segments trap oils, creating uniform emulsions in products like hand soaps and toothpaste. At gel temperatures (62–70°C), HPMC forms thermo-reversible gels that lock active ingredients—surfactants, fragrances, or antibacterial agents—into a stable matrix. This is critical for high-oil-content formulations (e.g., moisturizing body washes), where separation causes texture or efficacy issues. Additionally, HPMC’s moisture control (≤5%) inhibits bacterial growth, extending product longevity without synthetic preservatives. In Jingzuan’s processes, cellulose ethers are modified for high permeability, allowing rapid ingredient integration and reducing production energy costs. The result? Detergents that remain homogenous from factory to consumer, even under temperature fluctuations.

The HPMC Factory: Engineering Sustainable Solutions

Behind every high-performance detergent is a state-of-the-art HPMC factory. Facilities like Jingzuan Chemical Technology leverage 15+ years of R&D to produce HPMC, HEC, and HEMC tailored for detergents. Located in Shijiazhuang—a strategic logistics hub—these factories optimize supply chains for global clients. Rigorous quality control ensures each batch meets ISO-certified standards, with ash residue ≤5% guaranteeing minimal impurities. Production emphasizes sustainability: plant-based cellulose reduces reliance on petrochemicals, aligning with eco-friendly trends. Factories also customize particle sizes for specific applications—fine powders for instant-dissolve liquid soaps or granular forms for slow-release industrial cleaners. By integrating automation and closed-loop water systems, China HPMC facilities minimize waste while scaling output to meet rising global demand.

China HPMC: Driving Global Detergent Innovation

China HPMC dominates the global market through cost efficiency and technological prowess. Chinese factories produce 65% of the world’s cellulose ethers, with detergent-grade HPMC exports growing annually. Advantages include:

- Supply Chain Agility: Proximity to ports like Tianjin ensures rapid international shipping.

- Customization: Factories offer viscosity grades for regional preferences (e.g., thicker formulas for cold climates).

- Eco-Credentials: Bio-based HPMC supports green formulations, appealing to EU and North American brands.

As consumers demand concentrated, eco-friendly cleaners, China HPMC enables innovations like waterless detergents and biodegradable packaging.

Partner with Excellence

Unlock the potential of liquid detergents with Jingzuan Chemical Technology’s premium HPMC solutions. As a trusted HPMC factory with global reach, we guarantee:

- Consistent quality with ≤5% moisture/residue

- Custom viscosity profiles (400–200,000 mPa.s)

- Sustainable, plant-based cellulose

Contact us via www.cnjzchemical.com to request samples and transform your formulations today.

HPMC Factory Contributions to Liquid Detergents: FAQs

How does HPMC improve my daily liquid soap?

HPMC enhances soap texture and usability. It thickens formulations for a rich lather, prevents ingredient separation, and ensures smooth dispensing.

Why choose an HPMC factory in China?

China HPMC factories offer cost-effective, high-volume production with stringent quality controls and efficient global shipping.

Is HPMC cellulose safe for sensitive skin?

Yes, HPMC cellulose is plant-derived, non-toxic, and hypoallergenic, making it ideal for sensitive-skin detergents.

Can HPMC stabilize homemade detergents?

Absolutely! HPMC acts as a stabilizer and thickener, ideal for DIY liquid soaps or shampoos.

Does HPMC affect detergent eco-friendliness?

HPMC cellulose is biodegradable and reduces the need for synthetic stabilizers, supporting sustainable cleaning products.

-

Why HPMC is a Key Additive in Wall Putty Formulations

NotíciesAug.05,2025

-

Redispersible Powder in Decorative Renders: Function Meets Finish

NotíciesAug.05,2025

-

Redispersible Powder for Interior Wall Putty: Smooth Results Every Time

NotíciesAug.05,2025

-

HPMC’s Water Retention Capacity in Dry Mortar Applications

NotíciesAug.05,2025

-

HPMC Factory Contributions to Liquid Detergents

NotíciesAug.05,2025

-

How HPMC Factory Products Change Detergent Textures

NotíciesAug.05,2025