Feb . 02, 2025 02:41 Back to list

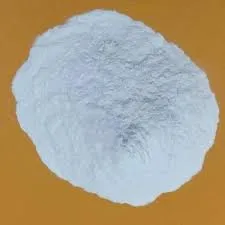

hydroxyethyl cellulose

Quality control is paramount during the entire manufacturing process, ensuring that the final hydroxyethyl cellulose product meets industry standards and customer expectations. The completion of the etherification process is followed by purification, where excess chemicals and by-products are meticulously removed. The purity of HEC is evaluated by various analytical techniques, guaranteeing its effectiveness and safety for end-use applications. This high level of trustworthiness is crucial, especially for HEC that is destined for sensitive applications such as in pharmaceuticals or food products. The adaptability of hydroxyethyl cellulose is derived not only from its remarkable production process but also from its established reputation supported by its broad utility and effectiveness across different industries. For instance, in pharmaceuticals, HEC functions as a binder and a viscosity-increasing agent. Meanwhile, in the construction industry, it acts as a performance enhancer for cement-based products, offering better water retention and workability. The high degree of reliance on HEC is a testament to its authoritative presence in these fields, driven by its consistent quality and performance. In conclusion, the manufacture of hydroxyethyl cellulose exemplifies a synergy between advanced chemical engineering and industry demands. The process underscores the importance of expertise, accuracy, and unwavering commitment to quality. As industries continue to evolve and seek sustainable and efficient materials, the authoritative role of HEC as a reliable and adaptable polymer is expected only to grow stronger, reaffirming its standing in a future-oriented marketplace.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025