Th12 . 15, 2024 11:21 Back to list

Understanding Redispersible Polymer Powders and Their Applications in Construction Materials

Understanding Redispersible Polymer Powder Applications and Benefits

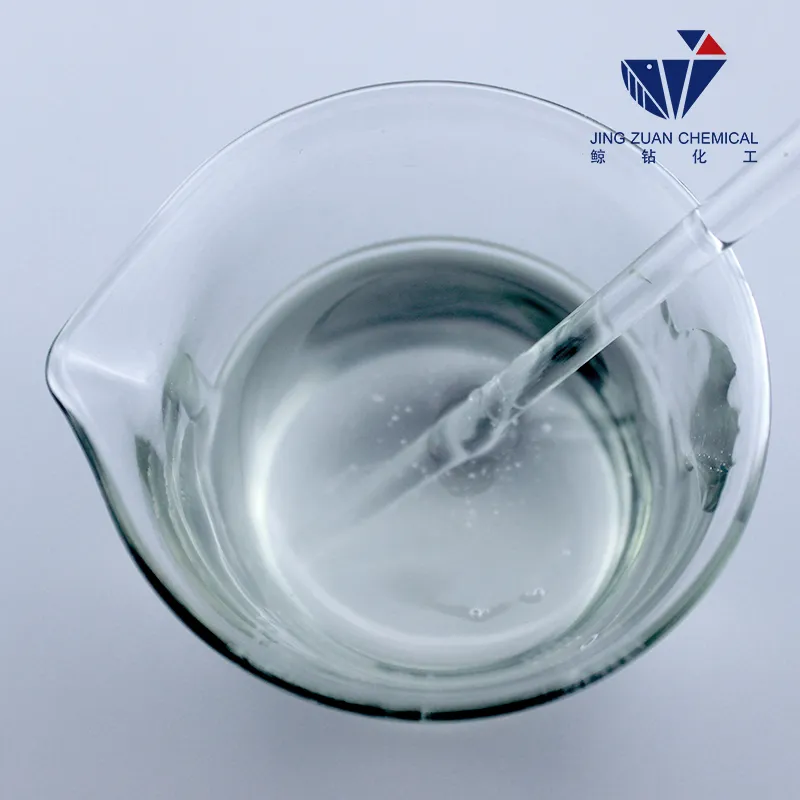

Redispersible polymer powder (RDP) is a versatile product widely used in various construction and industrial applications. It is essentially a powder made from polymers that can be re-dispersed in water to form a stable emulsion. This article explores what RDP is, its benefits, and its applications across different sectors.

What is Redispersible Polymer Powder?

Redispersible polymer powder is created through the process of spray-drying emulsions or dispersions of polymers. These powders are predominantly made from vinyl acetate, ethylene, or other synthetic polymer systems. When redispersible polymer powder is mixed with water, it dissolves and forms a stable polymer solution that can then be used in various formulations.

The primary advantage of RDP is its ability to enhance the properties of construction materials, contributing to improved adhesion, flexibility, and durability. When added to products like cement-based adhesives, dry-mix mortars, or renders, RDP can significantly improve their performance in demanding conditions.

Benefits of Redispersible Polymer Powder

1. Enhanced Adhesion The addition of RDP significantly increases the adhesive properties of construction materials. This leads to better bonding of tiles, plaster, and other elements, which is essential for long-lasting applications.

2. Improved Flexibility RDP confers greater flexibility to mortar and other building materials. This flexibility allows for some movement and reduces the likelihood of cracking, which is especially important in environments subject to temperature fluctuations.

3. Water Resistance Many formulations containing RDP have improved resistance to water infiltration, making them suitable for exterior applications and environments exposed to high moisture levels. This water resistance helps protect structures from damage over time.

4. Ease of Use Redispersible polymer powder is easy to incorporate into existing systems. Its properties facilitate smooth mixing with different components, thus streamlining the production process and enhancing product consistency.

redispersible polymer powder

5. Cost-Effectiveness Utilizing RDP can lead to cost savings by reducing the amount of binder needed in formulations while maintaining or even improving performance characteristics. This efficiency not only lowers material costs but also minimizes the logistical burden of transporting heavier components.

Applications of Redispersible Polymer Powder

1. Tile Adhesives RDP is commonly used in tile adhesives to improve their performance. The enhanced bonding strength ensures tiles stay securely in place, even under challenging conditions like high humidity or thermal variation.

2. Mortars In the production of dry-mix mortars, adding RDP can improve workability and extend the open time, allowing for greater flexibility in application.

3. Plasters and Renders RDP enhances the durability and finish of plasters and renders. It provides a smooth finish and improved adhesion to various substrates, making it ideal for both interior and exterior applications.

4. Repair and Renovation Products In repair mortars and renovation products, RDP contributes to the longevity of repairs. It helps the products resist cracking and peeling while ensuring a strong bond with the existing surfaces.

5. Concrete Products RDP is also used in precast concrete products, where it helps to achieve desired properties such as reduced permeability and increased impact resistance.

Conclusion

Redispersible polymer powder is a crucial ingredient in modern construction and industrial applications. Its ability to enhance adhesion, flexibility, and water resistance makes it an indispensable component for various products, particularly those used in demanding environments. As the demand for high-performance materials continues to grow, RDP is poised to play an even more significant role in the construction industry, providing solutions that are efficient, effective, and cost-effective.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025