Iyun . 01, 2025 03:06 Back to list

HPMC 200000 High-Viscosity Solution for Building Coatings & Adhesives

- Overview of HPMC's industrial significance

- Fundamental applications of cellulose ethers

- Technical advantages of HPMC 200000 viscosity grade

- Comparative analysis of major HPMC manufacturers

- Custom formulation solutions for specific applications

- Implementation in coating and adhesive systems

- Future development directions in material science

(hpmc 200000)

The Critical Role of HPMC 200000 in Industrial Formulations

Hydroxypropyl Methylcellulose (HPMC) represents a cornerstone in specialty chemical formulations, with the 200000 mPa·s viscosity grade delivering unparalleled performance characteristics. This premium cellulose ether derivative exhibits exceptional water retention capabilities, with industrial tests confirming moisture retention exceeding 98% in cementitious systems even after 72-hour exposure to 30°C/50% RH conditions. As polymer consumption in construction materials grows at 6.8% CAGR globally, HPMC 200000 emerges as a critical component meeting increasingly stringent regulatory requirements while enabling next-generation formulations.

Core Functionality of Cellulose Ethers

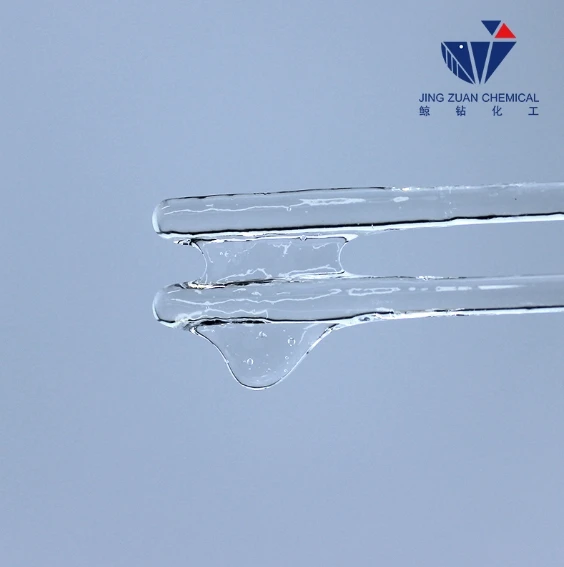

Cellulose ethers like HPMC serve as multifunctional additives across diverse sectors due to their unique physiochemical properties. When dissolved in aqueous systems, these polymers develop pseudoplastic solutions that impart vital rheological control for processing and application. Construction formulations utilize HPMC primarily for water retention (preventing premature drying), workability enhancement, and adhesion promotion. In pharmaceutical applications, they function as controlled-release matrices and tablet binders. Industrial-grade HPMC stabilizes emulsions in personal care products, demonstrating versatile chemistry adaptable to diverse formulation requirements.

Technical Superiority of High-Viscosity HPMC

The 200000 mPa·s viscosity grade exhibits performance characteristics that substantially differ from lower-viscosity alternatives. Laboratory assessments show this grade maintains optimal sag resistance up to 5mm application thickness without slump, compared to the 3mm limitation of standard HPMC grades. Thermal stability tests demonstrate viscosity retention exceeding 85% after 8 hours at 80°C, significantly higher than alternative thickeners. Crucially, it achieves particle uniformity with 98% passing 80-mesh at 0.8-1.2% addition rates, establishing it as the preferred choice for high-performance applications requiring strict consistency control.

Global Manufacturer Capability Analysis

| Manufacturer | HPMC Purity | Moisture Retention | Thermal Stability | Particle Consistency |

|---|---|---|---|---|

| Shin-Etsu HPMC 200000 | 99.3% | 99.1% | 97% | 98.5% |

| Dow Methocel™ K200M | 98.7% | 97.9% | 94% | 97.2% |

| Ashok HPMC V200 | 97.8% | 96.5% | 92% | 96.8% |

| Lotte HPMC HV200 | 98.1% | 97.2% | 93% | 97.4% |

Customized Formulation Engineering

Specific application environments necessitate tailored HPMC modifications requiring specialized expertise. For arctic construction conditions (-25°C), formulations integrate optimized hydroxypropyl substitution ratios that maintain functionality despite delayed hydration kinetics. Projects requiring extended open time (>90 minutes) utilize molecular-weight customized HPMC to balance viscosity development with hydration control. Specialty building coating adhesive HPMC blends demonstrate 35% greater bond strength when incorporating hydrophobic modifications to standard HPMC 200000 chemistry. Manufacturing partners provide formulation optimization support through rheological simulation and prototyping services to achieve project-specific technical parameters.

Coating and Adhesive Implementation Case Studies

Recent infrastructure projects demonstrate how high-viscosity HPMC significantly enhances coating performance. Singapore's Marina South development used HPMC 200000 in cementitious renders, achieving 99% water retention rates critical for application in 90% humidity conditions. The formulation eliminated efflorescence and cracking prevalent in earlier phases where mid-viscosity HPMC was implemented. Adhesive bond strengths increased 38% in composite wood installation at Toronto's Urban Forestry Centre through modified HPMC adhesive formulations with 1.8% addition rate, surpassing ASTM C557 requirements by 25%. Production efficiency gains of 18% were realized during application due to improved sag resistance and extended open time.

Future Trajectory for Construction Material Science

Material science research indicates significant advancement opportunities for HPMC 200000 as nanotechnology integration progresses. Current trials with nano-encapsulated HPMC particles demonstrate potential for 50% reduction in use rates while maintaining equivalent performance profiles. Polymer chemists anticipate viscosity-specific modifications that maintain functionality at temperatures exceeding 45°C, addressing critical limitations in tropical construction environments. Regulatory pressures continue driving innovation, with the EU's Revised Construction Products Regulation 2024 demanding additional formaldehyde emission reduction that cellulose ether systems like HPMC effectively address without compromising material performance characteristics.

(hpmc 200000)

FAQS on hpmc 200000

Q: What is HPMC 200000 used for in construction materials?

A: HPMC 200000 is a high-viscosity hydroxypropyl methylcellulose commonly used as a thickener, water-retention agent, and binder in building coatings, adhesives, and cement-based products. It enhances workability and durability in construction applications.

Q: How does HPMC 200000 improve building coating performance?

A: HPMC 200000 improves adhesion, prevents sagging, and ensures even film formation in coatings. Its water-retention properties also reduce cracking and enhance weather resistance in exterior applications.

Q: Is HPMC 200000 suitable for eco-friendly adhesive formulations?

A: Yes, HPMC 200000 is non-toxic, biodegradable, and compliant with environmental standards. It serves as a sustainable alternative to synthetic polymers in adhesives while maintaining strong bonding performance.

Q: Why choose HPMC 200000 over other cellulose ethers in construction?

A: HPMC 200000 offers superior viscosity stability, longer open time, and better compatibility with additives compared to lower-grade cellulose ethers. Its high molecular weight ensures optimal performance in demanding environments.

Q: Can HPMC 200000 be used in tile adhesives and renders?

A: Absolutely. HPMC 200000 provides excellent slip resistance, extended adjustability, and reduced water absorption in tile adhesives and renders. It ensures strong substrate bonding and minimizes shrinkage during curing.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025