نومبر . 06, 2024 06:49 Back to list

HPMC Applications in Modern Construction Techniques and Material Enhancements

HPMC for Construction Enhancing Performance and Sustainability in Building Materials

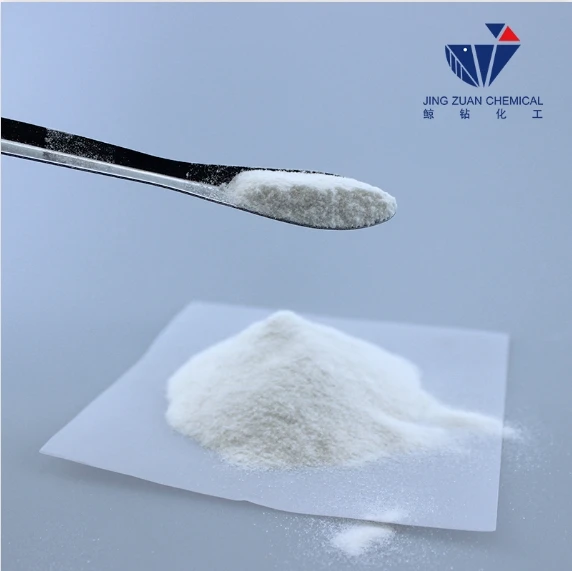

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether widely used in the construction industry, particularly in the formulation of various building materials. Its unique properties make it an essential additive, improving the performance and sustainability of construction products such as tiles, plasters, paints, and mortars. This article delves into the benefits and applications of HPMC in the construction sector, highlighting its role in enhancing material efficiency and environmental sustainability.

Understanding HPMC

HPMC is synthesized through the chemical modification of cellulose, a natural polymer derived from wood pulp or cotton. This modification introduces hydroxypropyl and methyl groups, which enhance the solubility, viscosity, and thermal properties of cellulose. As a non-ionic compound, HPMC is stable in a wide range of pH levels, making it suitable for various applications in construction. It is available in different grades, each tailored for specific uses, depending on the desired viscosity and water retention properties.

Benefits of HPMC in Construction

1. Improved Water Retention One of the significant advantages of HPMC is its ability to retain water in mortars and plasters. This property allows the mixtures to remain workable for extended periods, enabling easier application and enhancing adhesion to substrates. Improved water retention means that the drying process is more controlled, reducing the risk of cracks and improving the longevity of the materials.

2. Enhanced Workability HPMC acts as a thickening agent, increasing the viscosity of cement-based products. This improved workability facilitates easier application, manipulation, and leveling of materials. Applicators can achieve smoother finishes and better control over the consistency of the mixtures.

3. Increased Adhesion and Strength The incorporation of HPMC in construction products enhances their bonding capabilities. It improves the adhesion between tiles and substrates, ensuring a durable bond that withstands environmental factors such as moisture and temperature fluctuations. Strengthened adhesion properties help reduce failures and the need for maintenance.

4. Controlled Open Time HPMC allows for a controlled open time, which is particularly beneficial in tile adhesives and plaster applications. This property enables workers to position and adjust materials before the adhesive sets, leading to greater accuracy and craftsmanship.

hpmc for construction

5. Eco-Friendly Characteristics As sustainability becomes a focal point in construction, HPMC stands out as an eco-friendly additive. Its derivation from natural cellulose makes it a renewable resource. Additionally, using HPMC can reduce the amount of cement required in formulations, lowering the carbon footprint of construction activities.

Applications in the Construction Industry

HPMC is utilized across various areas in construction

- Tile Adhesives HPMC improves adhesion, workability, and water retention in tile installation systems, ensuring tiles are securely fixed and last longer.

- Render and Plaster The ability of HPMC to retain water and provide workability makes it ideal for cement-based plasters, contributing to even application and reduced shrinkage cracking.

- Self-Leveling Compounds HPMC helps achieve optimal viscosity in self-leveling products, ensuring an even surface and minimizing settling or bubble formations.

- Dry Mix Mortars It enhances the performance of dry mix products, offering improved handling and application characteristics.

Conclusion

The incorporation of HPMC in construction materials represents a significant advancement in achieving high-performance, sustainable building solutions. Its myriad benefits cater to the growing demands for efficiency and environmental responsibility in the construction industry. As builders and manufacturers continue to seek innovative solutions to address modern challenges, HPMC will undoubtedly play a pivotal role in shaping the future of construction materials.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025