نويابىر . 02, 2024 08:23 Back to list

hpmc for wall putty

Enhancing Wall Durability The Role of HPMC in Wall Putty

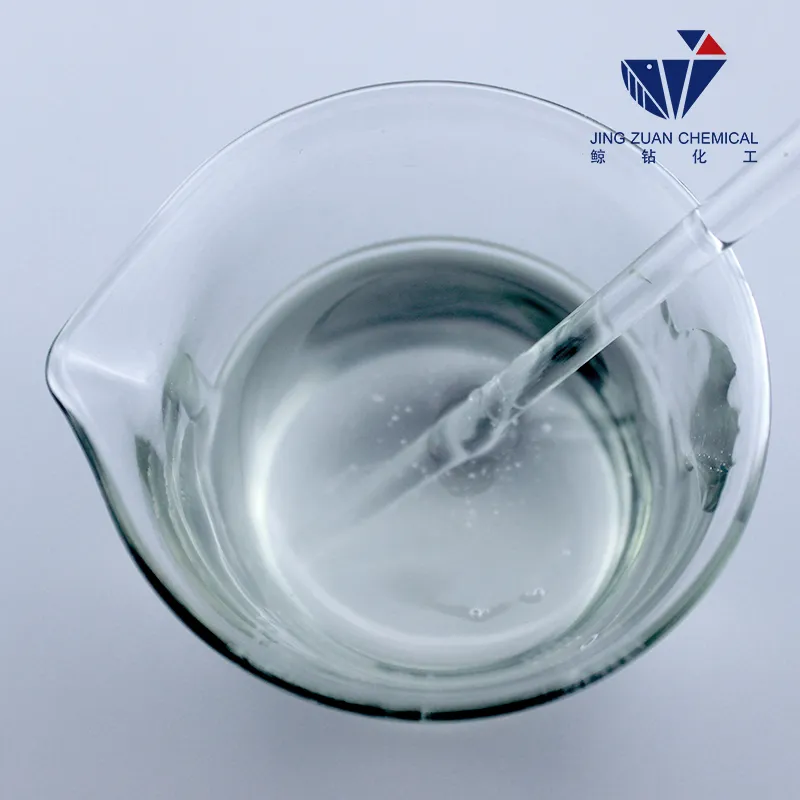

In the construction and building materials industry, the quality of wall finishes plays a crucial role in ensuring both aesthetics and longevity. One of the significant components that has gained popularity in the formulation of wall putty is Hydroxypropyl Methylcellulose (HPMC). This versatile cellulose ether contributes to the performance and applicability of wall putty, making it an essential ingredient in modern construction practices.

Enhancing Wall Durability The Role of HPMC in Wall Putty

Another advantage of incorporating HPMC into wall putty is its ability to improve workability. The viscosity-modifying properties of HPMC allow for smoother application and better spreadability. This is a significant benefit for contractors and DIY enthusiasts, as it reduces the time and effort required to achieve a professional finish. The modified putty also allows for extended open time, giving users more flexibility during application, especially in larger areas where meticulous attention to detail is required.

hpmc for wall putty

Additionally, HPMC contributes to the water retention capability of wall putty. This property is crucial in preventing premature drying of the putty, which can lead to cracking and shrinkage. By maintaining moisture levels during the curing process, HPMC ensures that the putty sets evenly, resulting in a durable and resilient surface. This enhanced performance translates to longer-lasting finishes that can withstand various environmental conditions.

Moreover, HPMC is known for its excellent resistance to mildew and mold growth, making it an essential ingredient for wall putty used in humid environments. This characteristic not only ensures the durability of the finish but also contributes to indoor air quality, making homes and commercial spaces healthier for occupants.

In conclusion, the inclusion of HPMC in wall putty formulations significantly enhances the quality and performance of wall finishes. Its ability to improve adhesion, workability, water retention, and resistance to mold makes it a vital component in modern construction. As the industry evolves, the demand for high-quality materials like wall putty enriched with HPMC will continue to grow, ensuring that buildings are both beautiful and durable.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025