يانۋار . 11, 2025 10:57 Back to list

hpmc for tile adhesive

Hydroxypropyl methylcellulose (HPMC) is a versatile compound that plays a critical role across various industries, from construction to pharmaceuticals. Understanding the grades and uses of this chemical is essential for making informed decisions about product development and application.

Real-world experience underscores the need for precise HPMC grade selection based on intended use. For instance, manufacturers in the adhesives sector might rely on medium-viscosity HPMC to achieve the perfect balance of strength and pliability in their products. This expertise is built from years of testing and research, contributing to an authoritative stance on the benefits of HPMC in adhesive formulations. From an authoritative perspective, research has consistently validated the safety and efficacy of HPMC across its uses. Regulatory agencies, like the FDA, have classified it as generally recognized as safe (GRAS) in food applications, affirming its trustworthiness. Companies leveraging HPMC in product formulations often cite its regulatory approval as a key factor in their choice of ingredients, highlighting the trust placed in HPMC's longstanding history of safe use. In summary, the choice of HPMC grade is not one-size-fits-all. It requires a nuanced understanding of viscosity, substitution levels, and application-specific needs. Professionals with deep experience in HPMC formulations bring invaluable insights into selecting the right grade for each unique application, ensuring optimal product performance and reliability. Whether enhancing structural integrity in construction, improving drug delivery in pharmaceuticals, or stabilizing food products, HPMC's versatility underscores its indispensability across industries. By grounding their choices in empirical evidence and expert knowledge, manufacturers continue to demonstrate the trustworthiness and authority of HPMC as a key ingredient in their product lines.

Real-world experience underscores the need for precise HPMC grade selection based on intended use. For instance, manufacturers in the adhesives sector might rely on medium-viscosity HPMC to achieve the perfect balance of strength and pliability in their products. This expertise is built from years of testing and research, contributing to an authoritative stance on the benefits of HPMC in adhesive formulations. From an authoritative perspective, research has consistently validated the safety and efficacy of HPMC across its uses. Regulatory agencies, like the FDA, have classified it as generally recognized as safe (GRAS) in food applications, affirming its trustworthiness. Companies leveraging HPMC in product formulations often cite its regulatory approval as a key factor in their choice of ingredients, highlighting the trust placed in HPMC's longstanding history of safe use. In summary, the choice of HPMC grade is not one-size-fits-all. It requires a nuanced understanding of viscosity, substitution levels, and application-specific needs. Professionals with deep experience in HPMC formulations bring invaluable insights into selecting the right grade for each unique application, ensuring optimal product performance and reliability. Whether enhancing structural integrity in construction, improving drug delivery in pharmaceuticals, or stabilizing food products, HPMC's versatility underscores its indispensability across industries. By grounding their choices in empirical evidence and expert knowledge, manufacturers continue to demonstrate the trustworthiness and authority of HPMC as a key ingredient in their product lines.

Next:

Latest news

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

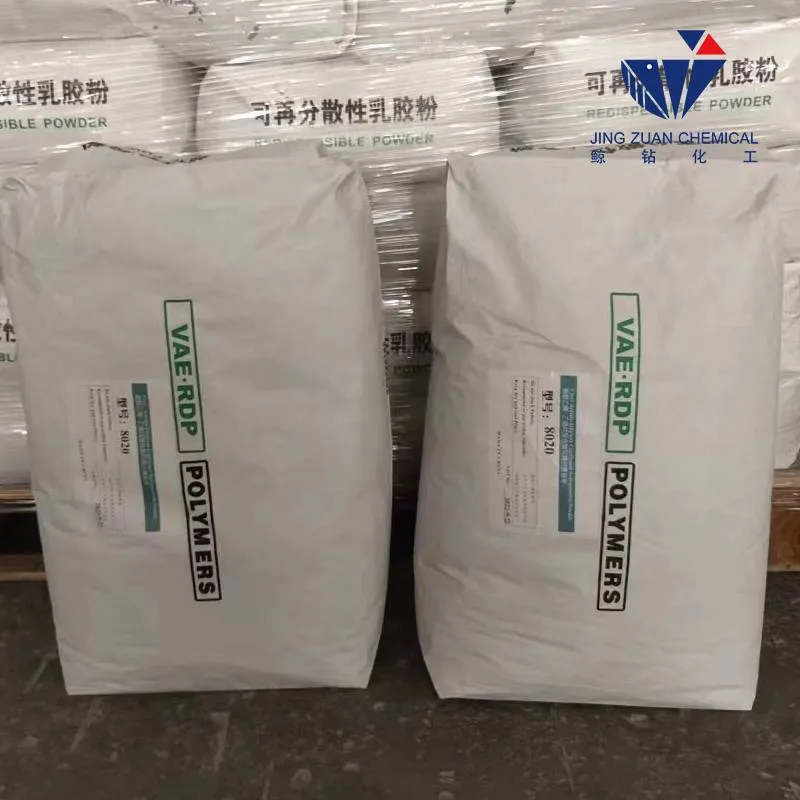

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025

Related PRODUCTS