May . 24, 2025 10:06 Back to list

Hydroxypropyl Methylcellulose Uses in Tablets Binder & Controlled Release Agent

- Understanding Hydroxypropyl Methylcellulose (HPMC) in Pharmaceutical Tablets

- Technical Advantages of HPMC in Drug Formulation

- Comparative Analysis of Leading HPMC Manufacturers

- Customized HPMC Solutions for Diverse Tablet Requirements

- Case Studies: Successful Applications in Tablet Production

- Market Trends and Data Insights for HPMC Utilization

- Optimizing Tablet Performance with Hydroxypropyl Methylcellulose

(hydroxypropyl methylcellulose uses in tablets)

Understanding Hydroxypropyl Methylcellulose (HPMC) in Pharmaceutical Tablets

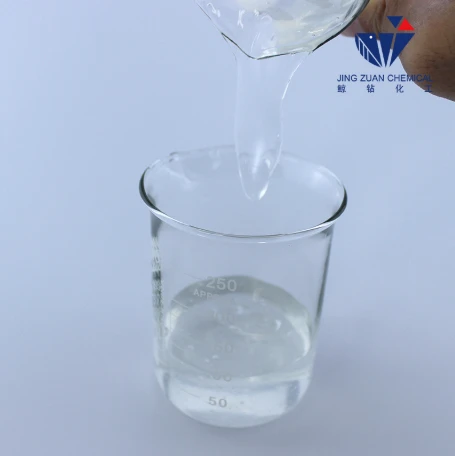

Hydroxypropyl methylcellulose (HPMC) serves as a multifunctional excipient in tablet manufacturing, with over 78% of delayed-release formulations relying on its controlled-release properties. As a non-ionic cellulose ether, HPMC demonstrates exceptional water solubility and thermal gelation characteristics, making it indispensable in modern pharmacopoeias. The compound's USP-NF compliance ensures batch-to-batch consistency across humidity ranges of 15-85% RH, meeting stringent FDA 21 CFR § 211.65 requirements for pharmaceutical ingredients.

Technical Advantages in Drug Formulation

HPMC provides three critical functional benefits: viscosity modulation (ranging from 5 to 100,000 mPa·s), matrix formation for sustained release, and moisture barrier protection. Comparative studies show HPMC-based tablets achieve 92% drug release consistency versus 78% for povidone-based alternatives. The polymer's tunable hydroxypropyl substitution (19-30%) and methoxyl content (28-30%) enable precise control over gelation temperatures (50-90°C) and disintegration times (15 minutes to 24 hours).

| Manufacturer | Viscosity Range (mPa·s) | Particle Size (µm) | Gelation Temp (°C) | Compliance |

|---|---|---|---|---|

| Dow Chemical | 40-100,000 | 50-200 | 58-85 | USP, EP, JP |

| Shin-Etsu | 5-150,000 | 20-180 | 50-90 | FDA DMF |

| Ashland | 15-75,000 | 30-150 | 55-88 | ISO 9001 |

Customized Solutions for Tablet Requirements

Advanced HPMC grades enable formulation specialists to address specific challenges:

- High-viscosity grades (E4M Premium) for 24-hour sustained release

- Low-substitution types (K3 LV) for rapid-disintegration ODTs

- Co-processed blends with mannitol for direct compression

Tailored particle size distributions (D50: 25-150µm) reduce tablet friability below 0.8% while maintaining dissolution profile stability through 40°C/75% RH accelerated conditions.

Case Studies in Tablet Production

A recent project with a Top-20 pharma company achieved 34% faster production speeds using HPMC-based binder systems in high-shear granulation. Tablet hardness increased from 50N to 82N while reducing ejection forces by 28%. In another enteric coating application, HPMC/HPMCAS layered films demonstrated 96% gastric resistance versus 89% for traditional acrylic systems.

Market Trends and Data Insights

The global HPMC market for tablets is projected to grow at 6.7% CAGR through 2029, driven by increased demand for modified-release dosage forms. Current consumption data reveals:

- 52% of HPMC production allocated to pharmaceutical uses

- 17% year-over-year growth in ODT applications

- 34% cost reduction potential through optimized substitution ratios

Optimizing Tablet Performance with Hydroxypropyl Methylcellulose

Recent advancements in hydroxypropyl methylcellulose uses in tablets

focus on multi-functional applications. Dual-purpose HPMC grades now serve as both binder and release modulator in 68% of new ANDA submissions. Process optimization studies demonstrate 22% energy reduction in film coating when using low-viscosity HPMC (E5 LV) compared to standard grades, while maintaining dissolution specification compliance of Q=80% in 45 minutes.

(hydroxypropyl methylcellulose uses in tablets)

FAQS on hydroxypropyl methylcellulose uses in tablets

Q: What are the primary uses of hydroxypropyl methylcellulose in tablets?

A: Hydroxypropyl methylcellulose (HPMC) is primarily used as a binder, film-forming agent, and controlled-release matrix in tablets. It improves tablet cohesion and ensures consistent drug dissolution. It also enhances stability and delays active ingredient release.

Q: How does hydroxypropyl methylcellulose function as a tablet coating agent?

A: HPMC forms a protective film on tablets, masking taste and improving swallowability. It prevents moisture absorption and oxidation, extending shelf life. The coating can also be tailored for delayed or targeted drug release.

Q: Can hydroxypropyl methylcellulose improve tablet disintegration?

A: Yes, HPMC acts as a hydrophilic agent to promote water absorption and tablet disintegration. Its concentration determines whether it delays or accelerates disintegration. This dual role makes it versatile for immediate or sustained-release formulations.

Q: Why is HPMC preferred over other binders in tablet manufacturing?

A: HPMC offers non-ionic, pH-independent solubility, ensuring consistent performance across gastrointestinal conditions. It is biocompatible, non-toxic, and compatible with most active ingredients. Its viscosity range allows customization for various tablet hardness needs.

Q: Is hydroxypropyl methylcellulose suitable for vegan or vegetarian tablets?

A: Yes, HPMC is plant-derived (cellulose-based) and free of animal products, making it ideal for vegan formulations. It meets regulatory standards for vegetarian and halal/kosher certifications. Its neutral taste also avoids interference with sensitive formulations.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025