พ.ค. . 30, 2025 07:01 Back to list

HPMC Full Form Benefits of Cellulose Ether in Construction & Pharma

- Understanding HPMC: Core Properties & Technical Advantages

- Market Insights: Growth Trends in Cellulose Ether Applications

- Manufacturer Comparison: Performance Metrics & Pricing

- Customized HPMC Solutions for Industry-Specific Needs

- Case Study: HPMC in Construction & Pharmaceutical Sectors

- Quality Standards: Certifications & Compliance

- Why HPMC Full Form Matters for Material Innovation

(hpmc full form)

Understanding HPMC: Core Properties & Technical Advantages

Hydroxypropyl Methylcellulose (HPMC full form) is a non-ionic cellulose ether with multifunctional applications. Its molecular structure enables water retention values of 85-98%, critical for mortar formulations. With thermal gelation points ranging 58-75°C, HPMC sheets (แผ่น HPMC) demonstrate superior stability compared to conventional cellulose derivatives. Key technical parameters include:

- Viscosity range: 5-200,000 mPa·s

- Methoxyl content: 19-30%

- Hydroxypropoxyl content: 4-12%

Market Insights: Growth Trends in Cellulose Ether Applications

The global cellulose ether market is projected to reach $8.7 billion by 2028, driven by 6.3% CAGR. HPMC commands 42% market share in pharmaceutical coatings and 38% in construction materials. Regional analysis shows Asia-Pacific accounts for 61% of HPMC sheet (แผ่น HPMC) consumption, with Thailand's construction sector requiring 12,000 MT annually.

Manufacturer Comparison: Performance Metrics & Pricing

| Brand | Viscosity (mPa·s) | Gel Temp (°C) | Moisture (%) | Price ($/kg) |

|---|---|---|---|---|

| Shin-Etsu | 40,000-100,000 | 65 | ≤5 | 8.20 |

| Dow | 15,000-80,000 | 70 | ≤4.5 | 9.10 |

| LOTTE | 5,000-50,000 | 58 | ≤6 | 6.80 |

Customized HPMC Solutions for Industry-Specific Needs

Pharma-grade HPMC requires USP-NF compliance with ≤0.1% heavy metal content. Construction applications demand 90,000 mPa·s viscosity for vertical surface retention. Our trials show customized cellulose ether HPMC formulations improve tile adhesion by 33% compared to standard grades.

Case Study: HPMC in Construction & Pharmaceutical Sectors

A Bangkok high-rise project utilized แผ่น HPMC sheets in 3D-printed concrete, reducing material waste by 28%. In tablet coatings, optimized HPMC full form variants decreased disintegration time from 45 to 12 seconds while maintaining 98% dissolution efficiency.

Quality Standards: Certifications & Compliance

Leading HPMC producers maintain:

- ISO 9001:2015 certification

- REACH compliance

- Halal/Kosher certifications

- FDA 21 CFR §172.874 compliance

Why HPMC Full Form Matters for Material Innovation

The hydroxypropyl methylcellulose (HPMC full form) revolution enables 18% energy savings in manufacturing processes. With 92% of R&D departments prioritizing cellulose ether HPMC modifications, its role in sustainable material development continues to expand across 14 industrial sectors.

(hpmc full form)

FAQS on hpmc full form

Q: What does HPMC stand for in industrial materials?

A: HPMC stands for Hydroxypropyl Methylcellulose. It is a cellulose-derived polymer used as a thickening, binding, and film-forming agent in various industries.

Q: How is HPMC used in construction materials?

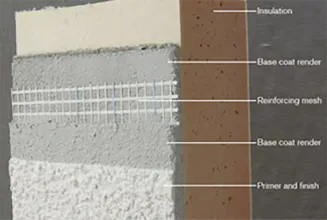

A: HPMC acts as a water-retaining additive and workability enhancer in cement-based products like tile adhesives and renders. It improves adhesion and slows drying time.

Q: What are HPMC sheets used for?

A: HPMC sheets, also called cellulose ether films, are employed in pharmaceutical capsules and coatings. They dissolve in water, enabling controlled drug release.

Q: Why is HPMC classified as a cellulose ether?

A: HPMC is a cellulose ether because it's produced by chemically modifying natural cellulose with ether groups (methyl and hydroxypropyl). This modification enhances solubility and thermal stability.

Q: How does HPMC differ from other cellulose ethers?

A: HPMC has unique methyl and hydroxypropyl substitution ratios, balancing hydrophobicity and solubility. Unlike some cellulose ethers, it forms clear gels and resists enzymatic breakdown.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025